PivotingtheFrontCuttingUnit

Down

1.Slowlylowerwingcuttingunitsuntilthecenterof

gravityshiftsandthecentercuttingunitrotates

downward.

2.Sitontheseat,starttheengine,andlowerthecenter

cuttingunituntilitisslightlyoffoftheoor.

3.Securetheheight-of-cutchainstotherearofthe

cuttingunit.

4.Pivotdampersupwardintopositionandsecurewith

clevispinandcotterpin.

AdjustingtheCuttingUnit

Pitch

MeasuringtheCuttingUnitPitch

Cuttingunitpitchisthedifferenceinheight-of-cutfrom

thefrontofthebladeplanetothebackoftheblade

plane.Tororecommendsabladepitchof1/4inch(6

mm).Thatisthebackofthebladeplaneis1/4inch(6

mm)higherthanthefront.

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthecuttingunittothedesiredheight-of-cut.

3.Rotate1bladesothatitpointsstraightforward.

4.Usingashortruler,measurefromtheoortothe

fronttipoftheblade.Rotatethebladetiptotherear

andmeasurefromtheoortothetipoftheblade.

5.Subtractthefrontdimensionfromtherear

dimensiontocalculatethebladepitch.

AdjustingtheFrontCuttingUnit

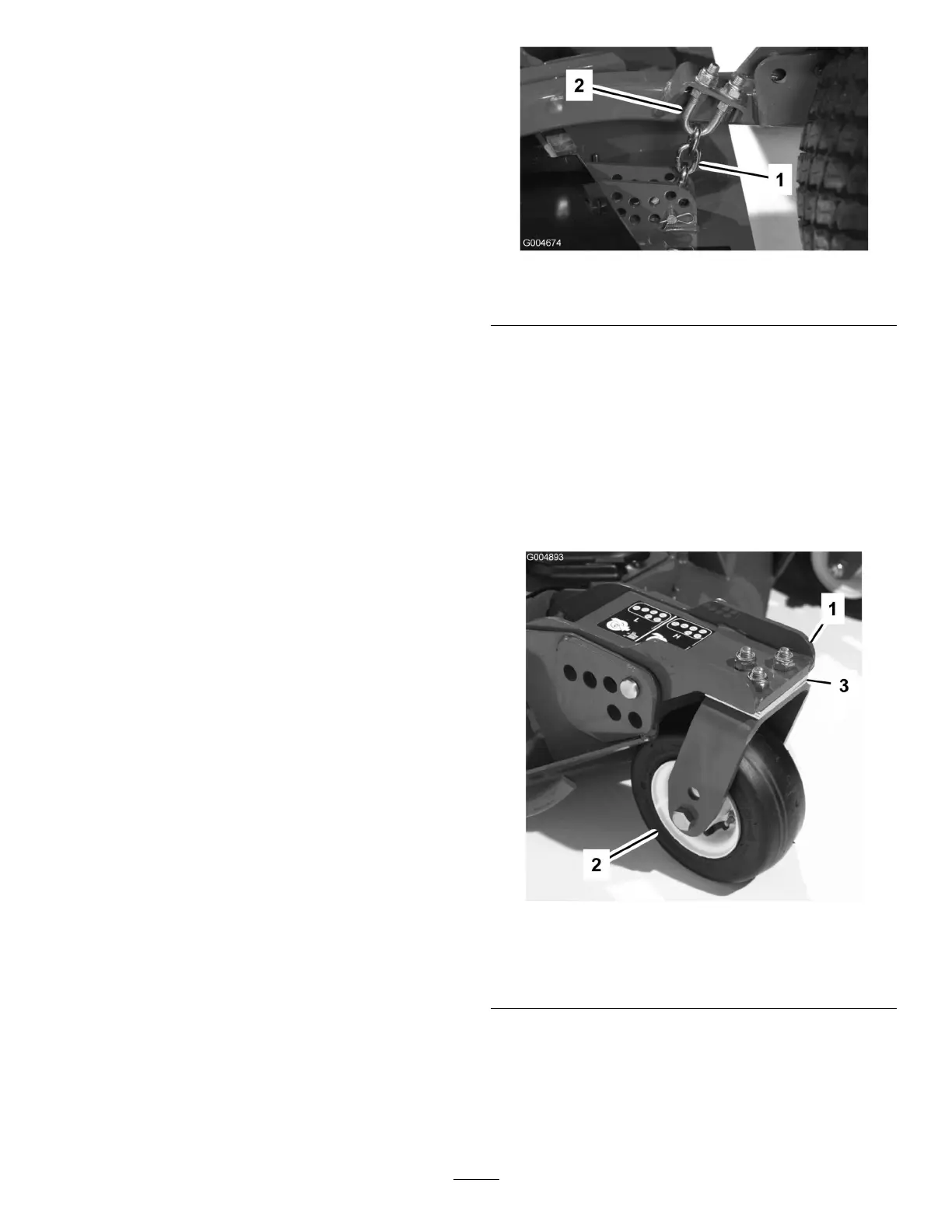

1.Loosenthejamnutsonthetoporbottomofthe

height-of-cutchainU-bolt(Figure76).

2.Adjusttheothersetofnutstoraiseorlowertherear

ofthecuttingunitandattainthecorrectcuttingunit

pitch.

3.Tightenthejamnuts.

Figure76

1.Height-of-cutchain

2.U-bolt

AdjustingtheWingCuttingUnits

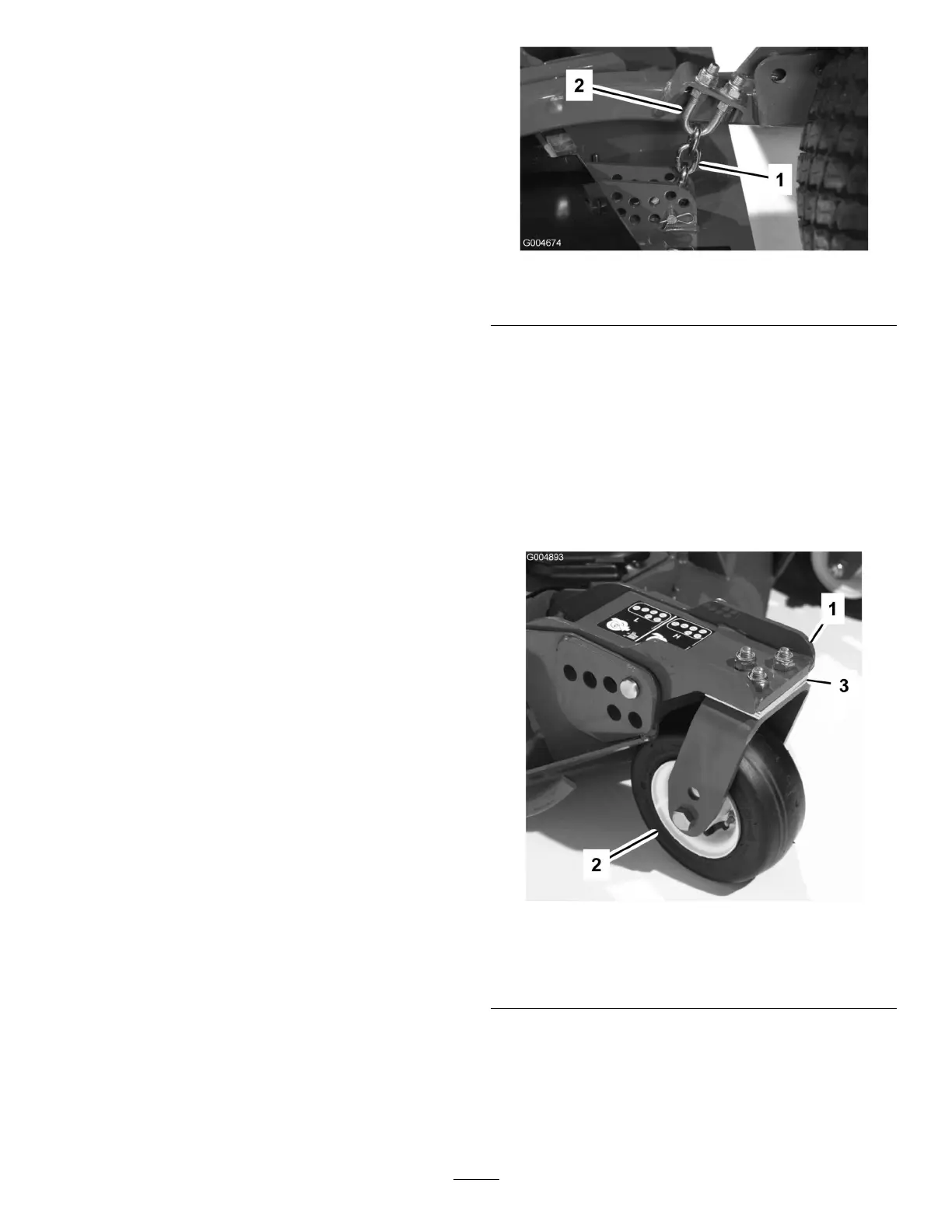

1.Removethecapscrewsandnutssecuringthecastor

armtothecastorfork(Figure77).

2.Repositiontheshims,asrequired,toraiseorlower

thecastorwheeluntilthecuttingunithasthecorrect

pitch.

3.Installthecapscrewsandnuts.

Figure77

1.Castorwheel4.Shims

2.Tensioningcap5.Axlemountingholes

3.Spacers

51

Loading...

Loading...