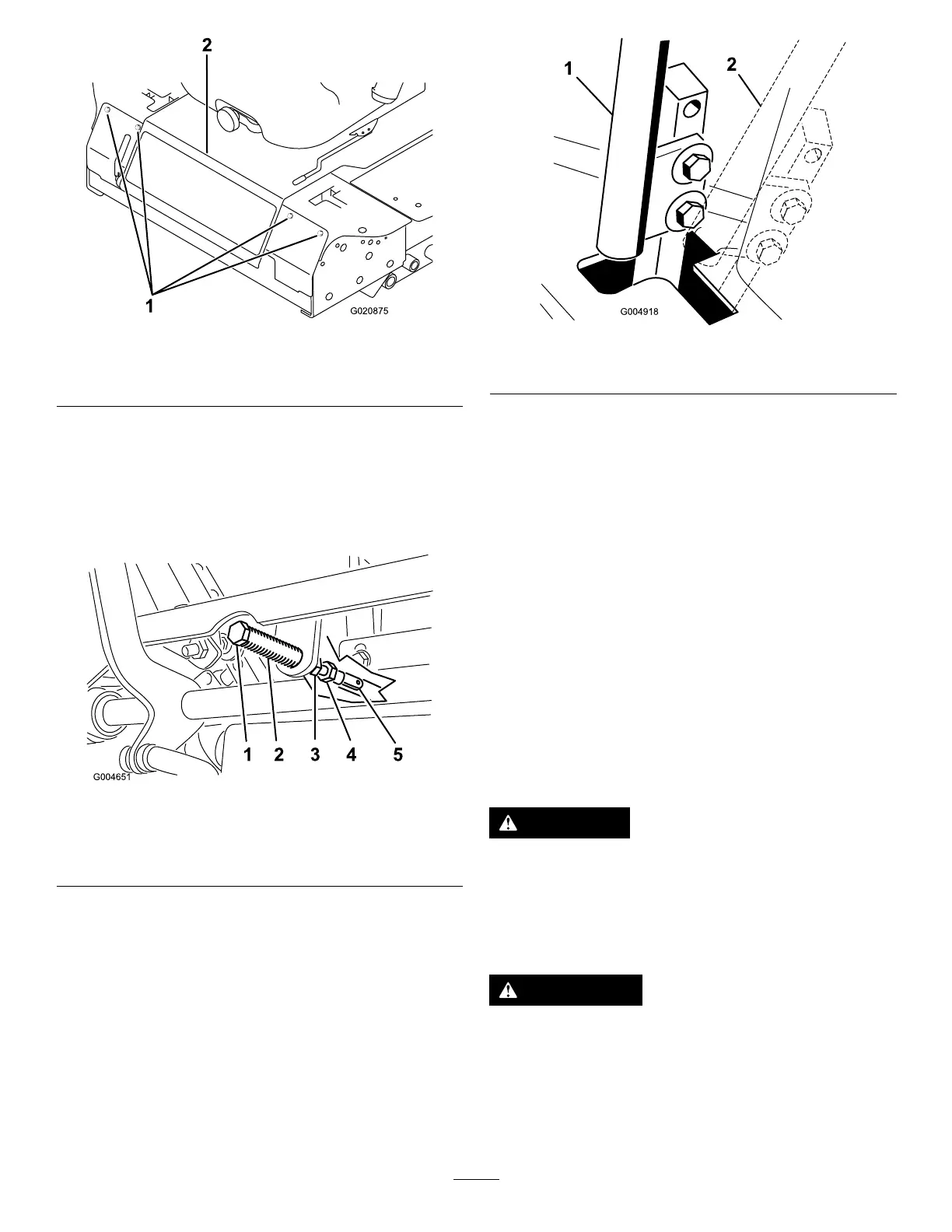

Figure52

1.Bolt

2.Controlpanel

4.MovethecontrollevertotheNEUTRALpositionbut

notlocked(Figure54).

5.Pulltheleverbackuntiltheclevispin(onanarm

abovethepivotshaft)contactstheendoftheslot(just

beginningtoputpressureonthespring)asshownin

Figure53.

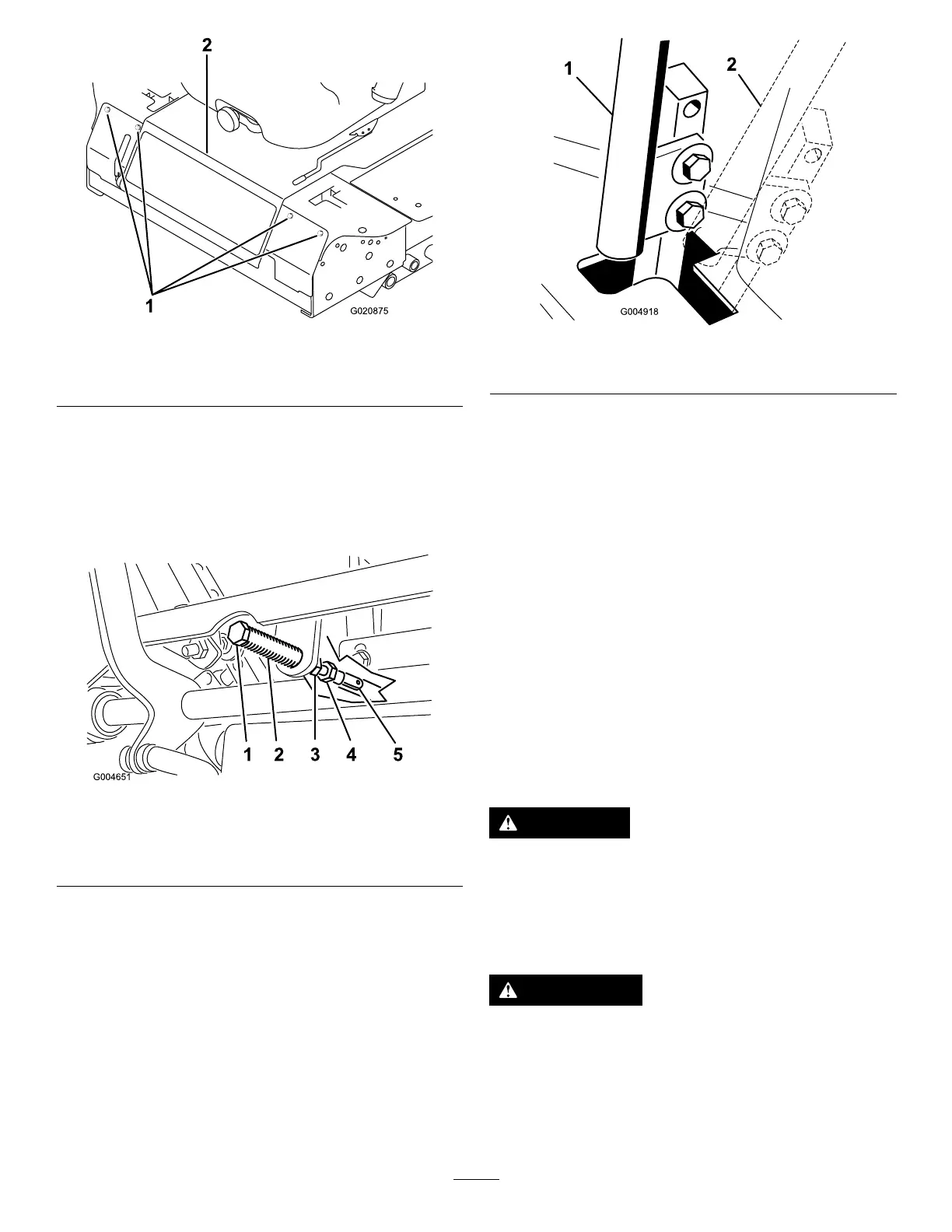

Figure53

1.Clevispin

4.Adjustmentbolt

2.Slot

5.Yoke

3.Jamnut

6.Checkwherethecontrolleverisrelativetonotchinthe

console(Figure54).

Note:Thecontrollevershouldbecentered,allowing

levertopivotoutwardtotheNEUTRAL-LOCKposition.

Figure54

1.NEUTRALposition2.NEUTRAL-LOCKposition

7.Ifadjustmentisneeded,loosenthenutandjamnut

againsttheyoke(Figure53).

8.Applyingslightrearwardpressureonthe

motion-controllever,turntheheadoftheadjustment

boltintheappropriatedirectionuntilthecontrollever

iscenteredintheNEUTRAL-LOCKposition(Figure53).

Note:Rearwardpressureontheleverkeepsthepin

attheendoftheslotandallowtheadjustmentboltto

movethelevertotheappropriateposition.

9.Tightenthenutandjamnut(Figure53).

10.Repeatsteps4through9fortheothercontrollever.

11.Installthefrontpanel.

AdjustingtheTractionDrive

forNeutral

Makethisadjustmentwiththedrivewheelsturning.

DANGER

Mechanicalorhydraulicjacksmayfailtosupport

themachineandcauseaseriousinjury.

•Usejackstandswhensupportingthemachine.

•Donotusehydraulicjacks.

WARNING

Theenginemustberunningtoperformthis

adjustment.Contactwithmovingpartsorhot

surfacesmaycausepersonalinjury.

Keephands,feet,face,clothing,andotherbody

partsawayfromrotatingparts,mufer,andother

hotsurfaces.

46

Loading...

Loading...