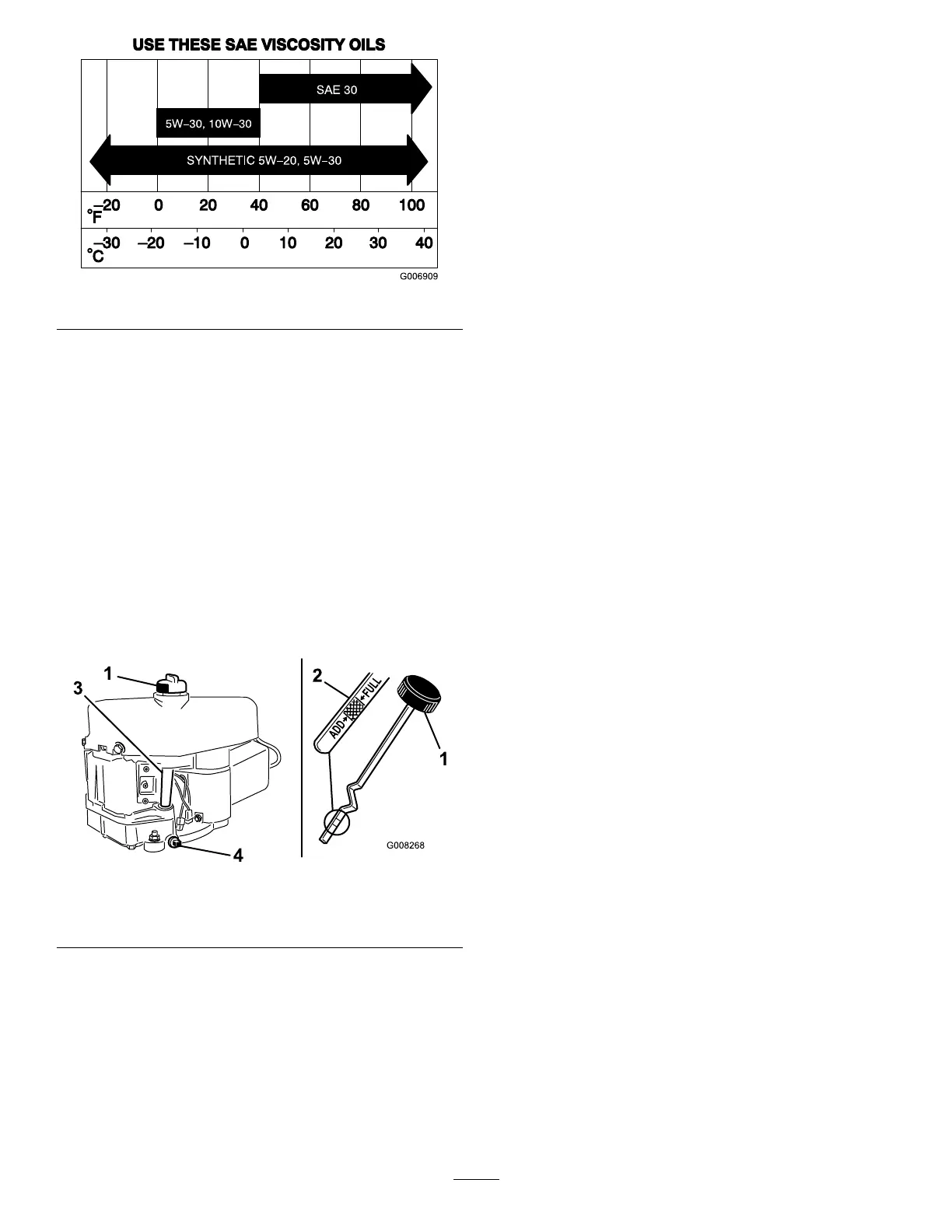

Figure22

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface.

2.Disengagetheblades(PTO).

3.Settheparkingbrake.

4.Stoptheengineandwaitforallmovingpartstostop.

5.Removetheignitionkey.

6.Openthehood.

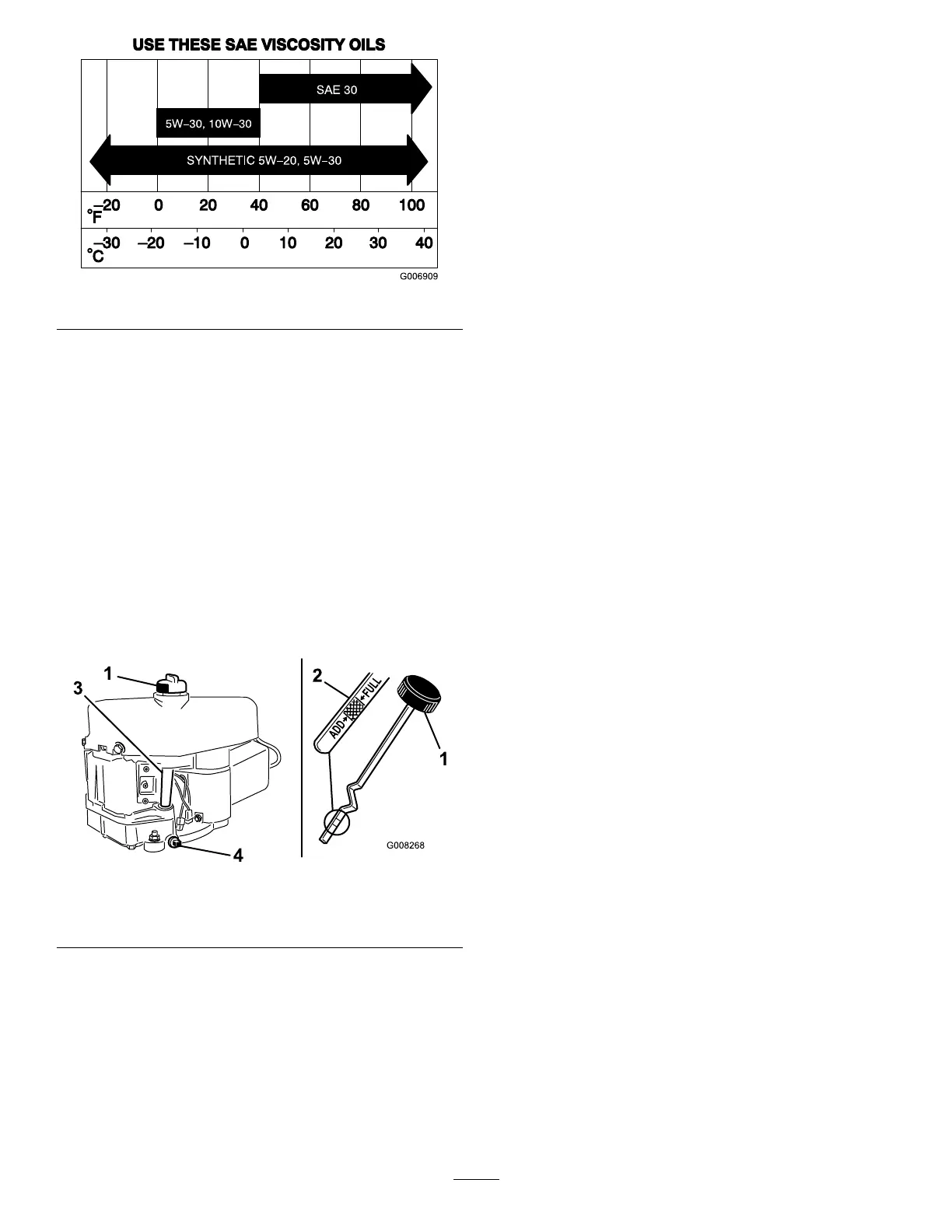

7.Cleanaroundthedipstick(Figure23)sothatdirt

cannotfallintothellerholeanddamagetheengine.

Figure23

1.Dipstick3.Fillertube

2.Metalend4.Drainplug

8.Unscrewthedipstickandwipethemetalendclean

(Figure23).

9.Screwthedipstickfullyontothellertube

(Figure23).

10.Unscrewthedipstickagainandlookatthemetal

end.Iftheengineoillevelislow ,slowlypouronly

enoughoilintothellertubetoraisetheleveltothe

Fullmarkonthedipstick.

Important:Donotoverllthecrankcasewith

engineoilandruntheengine;enginedamage

mayresult.

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours

Every50hours(Changeitmore

frequentlywhenoperatingthe

machineindustyordirtyconditions.)

1.Starttheengineandletitrunfor5minutes.

Note:Thiswarmstheoilsothatitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheothersidetoensurethattheoildrains

completely.

3.Disengagetheblades(PTO).

4.Settheparkingbrake.

5.Stoptheengineandwaitforallmovingpartstostop.

6.Removetheignitionkey.

7.Openthehood.

8.Placeapanbelowthedrainplug.

9.Removethedrainplugtoallowtheoiltodrain

(Figure23).

10.Whentheoilhasdrainedcompletely,insertthedrain

plugandtightenitsecurely.

Note:Recycletheusedengineoilproperly.

11.Cleanaroundthedipstickandunscrewthecap

(Figure23).

12.Slowlypourapproximately80%oftheengineoil

intothellertube(Figure23).

13.Checktheengineoillevel;refertosteps9and10of

CheckingtheEngineOilLevel.

ServicingtheSparkPlug

ServiceInterval:Every25hours—Checkthespark

plug.

Every100hours—Replacethespark

plug.

UseaChampionRC12YCorequivalentsparkplug.

Ensurethattheairgapbetweenthecenterandside

electrodesis0.030inch(0.76mm)beforeinstallingthe

sparkplug.Useasparkplugwrenchforremovingand

installingthesparkplugandagappingtoolorfeeler

gaugetocheckandadjusttheairgap.

RemovingtheSparkPlug

1.Disengagetheblades(PTO).

2.Settheparkingbrake.

24

Loading...

Loading...