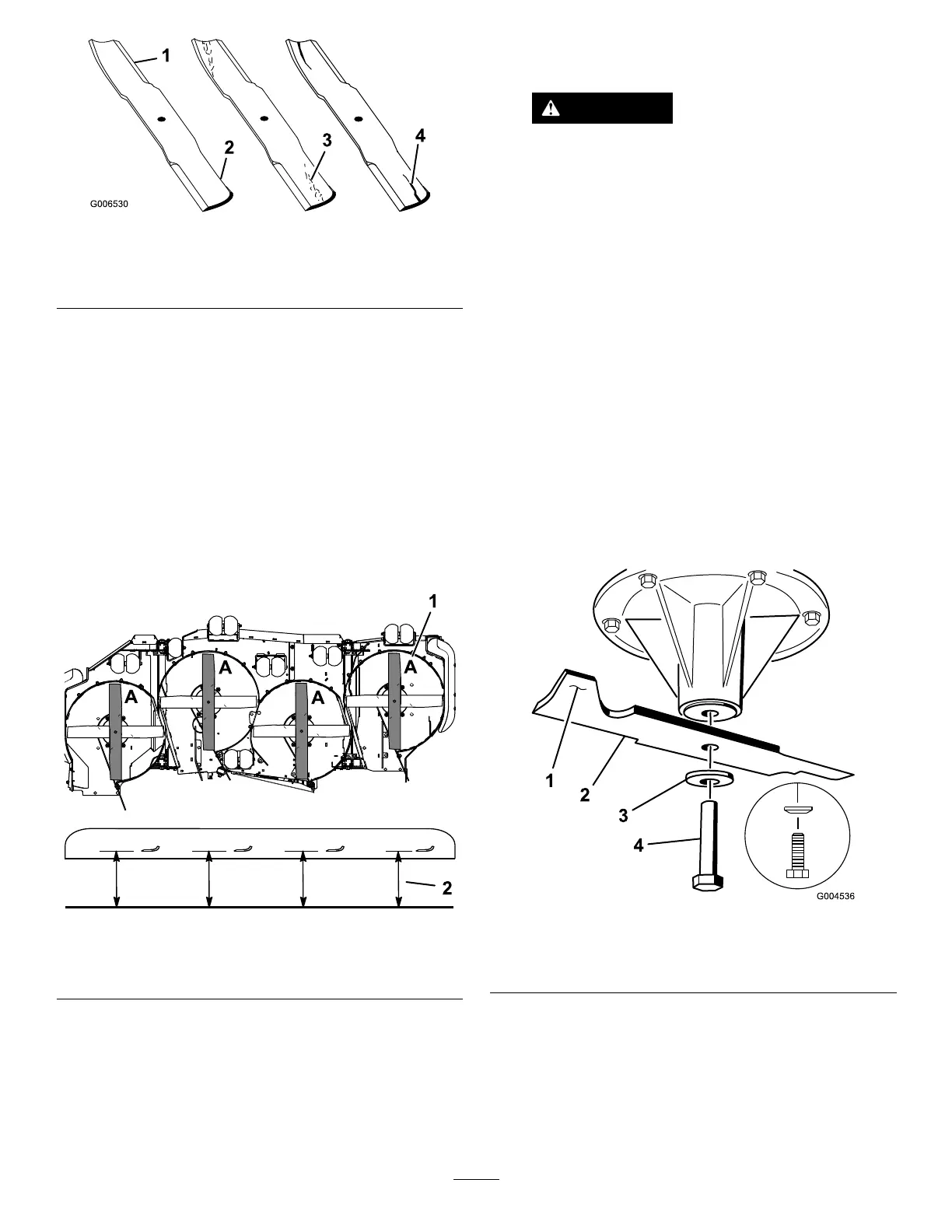

g006530

Figure76

1.Cuttingedge3.Wear/slotforming

2.Curvedarea4.Crack

CheckingforBentBlades

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Rotatethebladesuntiltheendsfaceforward

andbackward(Figure77).

4.Measurefromalevelsurfacetothecutting

edge,positionA,oftheblades(Figure77).

g243961

Figure77

1.PositionA

2.Measureherefromthe

bladetoahardsurface.

5.Rotatetheoppositeendsofthebladesforward.

6.Measurefromalevelsurfacetothecuttingedge

ofthebladesatthesamepositionasinstep4.

Note:Thedifferencebetweenthedimensions

obtainedinsteps4and5mustnotexceed3

mm(1/8inch).

Note:Ifthisdimensionexceeds3mm(1/8

inch),thebladeisbentandmustbereplaced.

DANGER

Abladethatisbentordamagedcould

breakapartandcouldseriouslyinjureor

killyouorbystanders.

•Alwaysreplacebentordamaged

bladewithanewblade.

•Neverleorcreatesharpnotchesin

theedgesorsurfacesofblade.

RemovingtheBlades

Replaceabladeifithitsanobject,ifthebladeisout

ofbalance,orifthebladeisbent.T oensureoptimum

performanceandcontinuedsafetyconformanceof

themachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturers

mayresultinnonconformancewithsafetystandards.

1.Holdthebladeendusingaragorathickly

paddedglove.

2.Removethebladebolt,curvedwasher,and

bladefromthespindleshaft(Figure78).

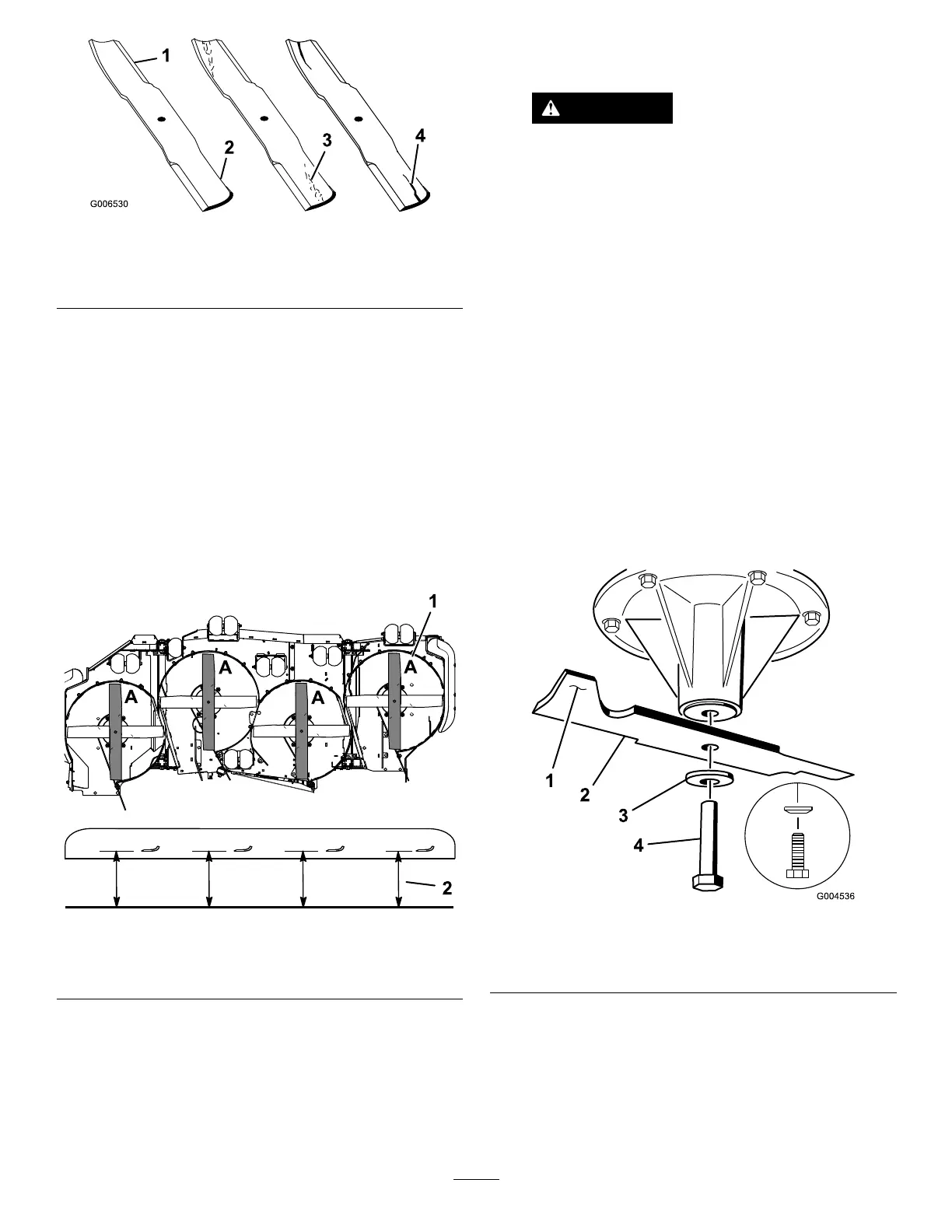

g004536

Figure78

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

60

Loading...

Loading...