RemovingtheBlades

Replaceabladeifithitsanobject,ifthebladeisoutofbalance,

orifthebladeisbent.Toensureoptimumperformanceand

continuedsafetyconformanceofthemachine,usegenuine

Tororeplacementblades.Replacementbladesmadebyother

manufacturersmayresultinnonconformancewithsafety

standards.

1.Holdthebladeendusingaragorathicklypadded

glove.

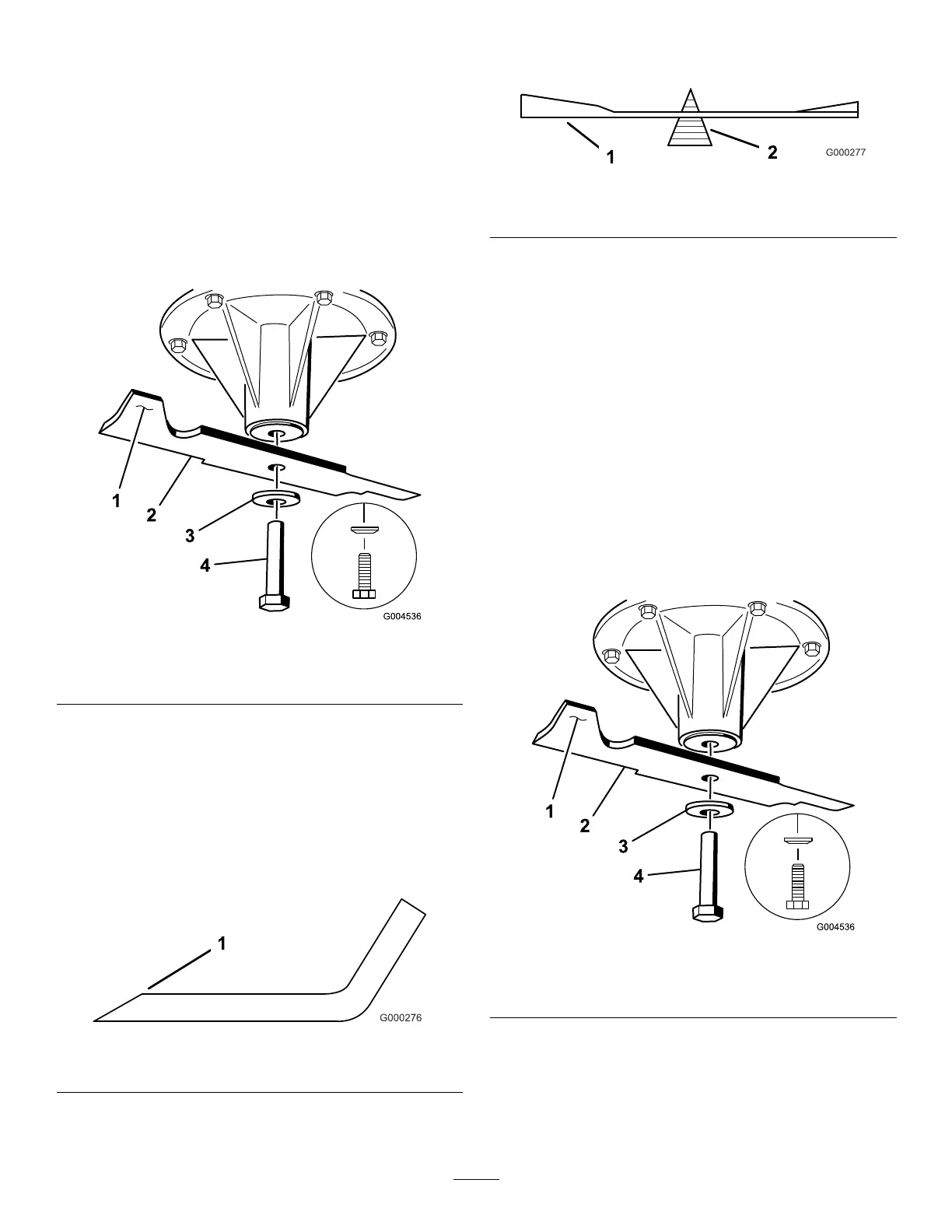

2.Removethebladebolt,curvedwasher,andbladefrom

thespindleshaft(Figure83).

Figure83

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure84).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsbalanceifyouremovethe

sameamountofmaterialfrombothcuttingedges.

Figure84

1.Sharpenattheoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure85).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalancedandreadytouse.

Figure85

1.Blade2.Balancer

3.Ifthebladeisnotbalanced,lesomemetalofftheend

ofthesailareaonly(Figure83).

4.Repeatthisprocedureuntilthebladeisbalanced.

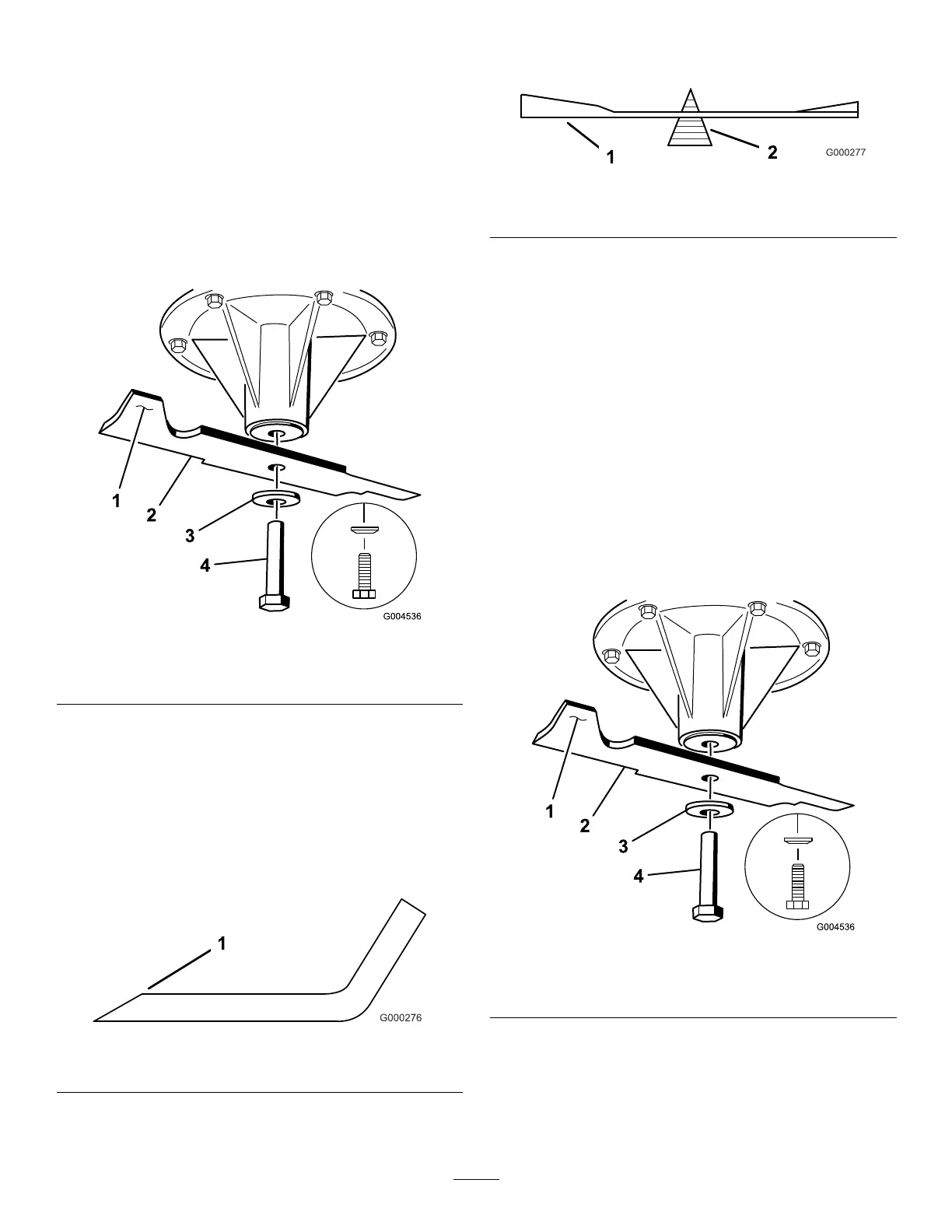

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure86).

Important:Thecurvedpartoftheblademust

pointupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthespringdiskandbladebolt(Figure86).

Note:Installthespring-diskconetowardthebolt

head.

3.Torquethebladeboltto115to150N∙m(85to

110ft-lb).

Figure86

1.Sailareaoftheblade3.Springdisk

2.Blade4.Bladebolt

57

Loading...

Loading...