Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Every200hours

•Cleantheowmeter(Moreoftenwhenusingwettablepowders).

Yearly

•Calibratetheowmeter.

CleaningtheFlowmeter

ServiceInterval:Every200hours

1.Thoroughlyrinseanddraintheentirespraying

system.

2.Removetheowmeterfromthesprayerandush

itwithcleanwater.

3.Removetheretainerringontheupstreamside

(

Figure11).

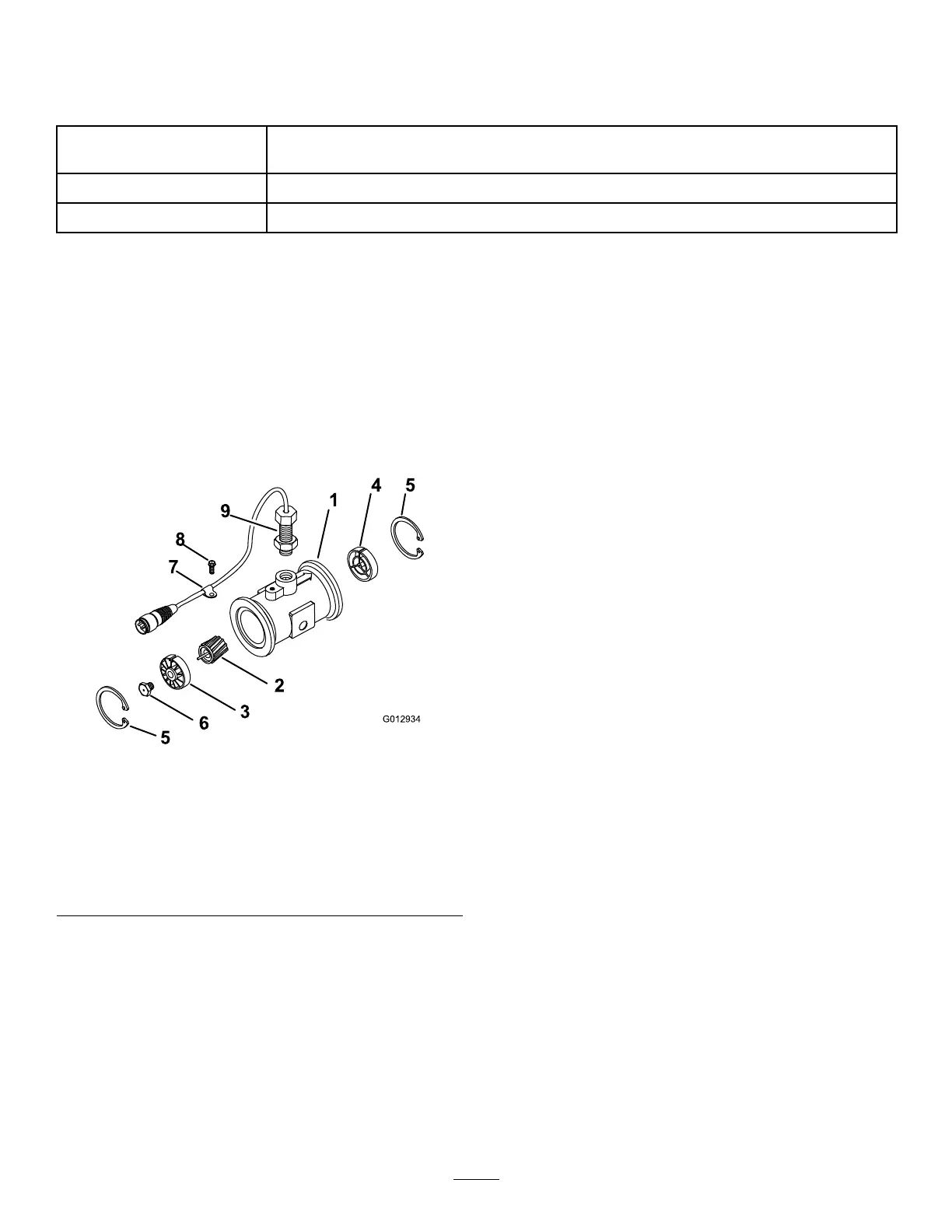

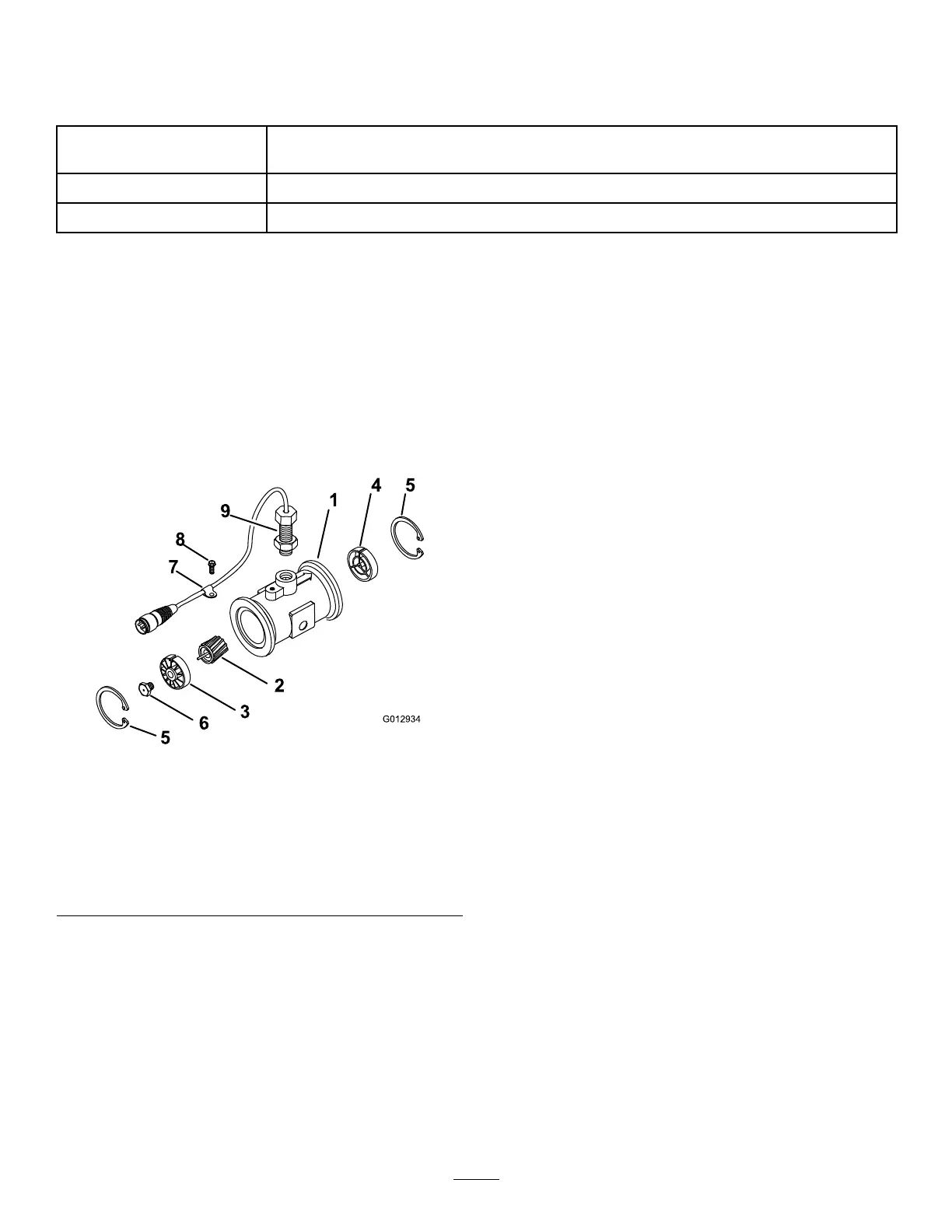

Figure11

1.Modiedangedbody

6.Turbinestudassembly

2.Rotorormagnetassembly

7.Cableclamp

3.Huborbearingassembly8.Threadscrew

4.Hubassembly(with

keywayup)

9.Sensorassembly

5.Retainerring10.Flow-reducingsleeve

4.Cleantheturbineandtheturbinehubtoremove

metallingsandanywettablepowders.

5.Inspecttheturbinebladesforwear.

Note:Holdtheturbineinyourhandandspinit.

Itshouldspinfreelywithverylittledrag.Ifitdoes

notspinfreely,replaceit.

6.Assembletheowmeter.

7.Installthesensoruntilitgentlytouchesthebottom

ofthehousing.

8.Carefullytightenthesensorretainingnuts.

9.Usealowpressure(5psior50kPa)airjettoensure

thattheturbinespinsfreely.Ifitdoesnotspinfreely,

loosenthehexstudonthebottomoftheturbine

hubby1/16ofaturnuntiltheturbinespinsfreely.

ProgrammingtheConsole

Computer

Withthecontrollerpoweroff,pressandholdtheCE

buttonandmovethepowerswitchontheconsole

computertotheOnposition.

Note:TurningthepowerswitchtotheOffpositionor

disconnectingtheconsolecablesdoesnoterasethedata

storedintheconsolecomputermemory.

Important:Thecalibrationguresgivenare

guidelinesonly;youshouldperformcalculationsfor

yourparticularmachineandsprayingapplication

situationandconditions.

Note:RefertoFigure9andthe

KeypadReferenceTable(page8)forthedescriptionand

functionofthekeysontheconsolecomputer.

Toprogramthecomputerconsole,refertoInitially

ProgrammingtheConsoleComputerintheOperation

section.

Note:Allthedataisretainedwhenyouturnthepower

switchtotheOffposition.

CalculatingtheBoomCalData

ThesettingsintheProControlXPareautomaticallyset

tothedefaultsettings.However,youcanchangethe

valuesifthenozzlespacinghaschanged.

CalculatetheBoomCalbymultiplyingthenumberof

spraytipsbythetipspacing.

Note:Boom1istheleftboom(fromtheoperating

position),Boom2isthecenterboom,andBoom3is

therightboom.

14

Loading...

Loading...