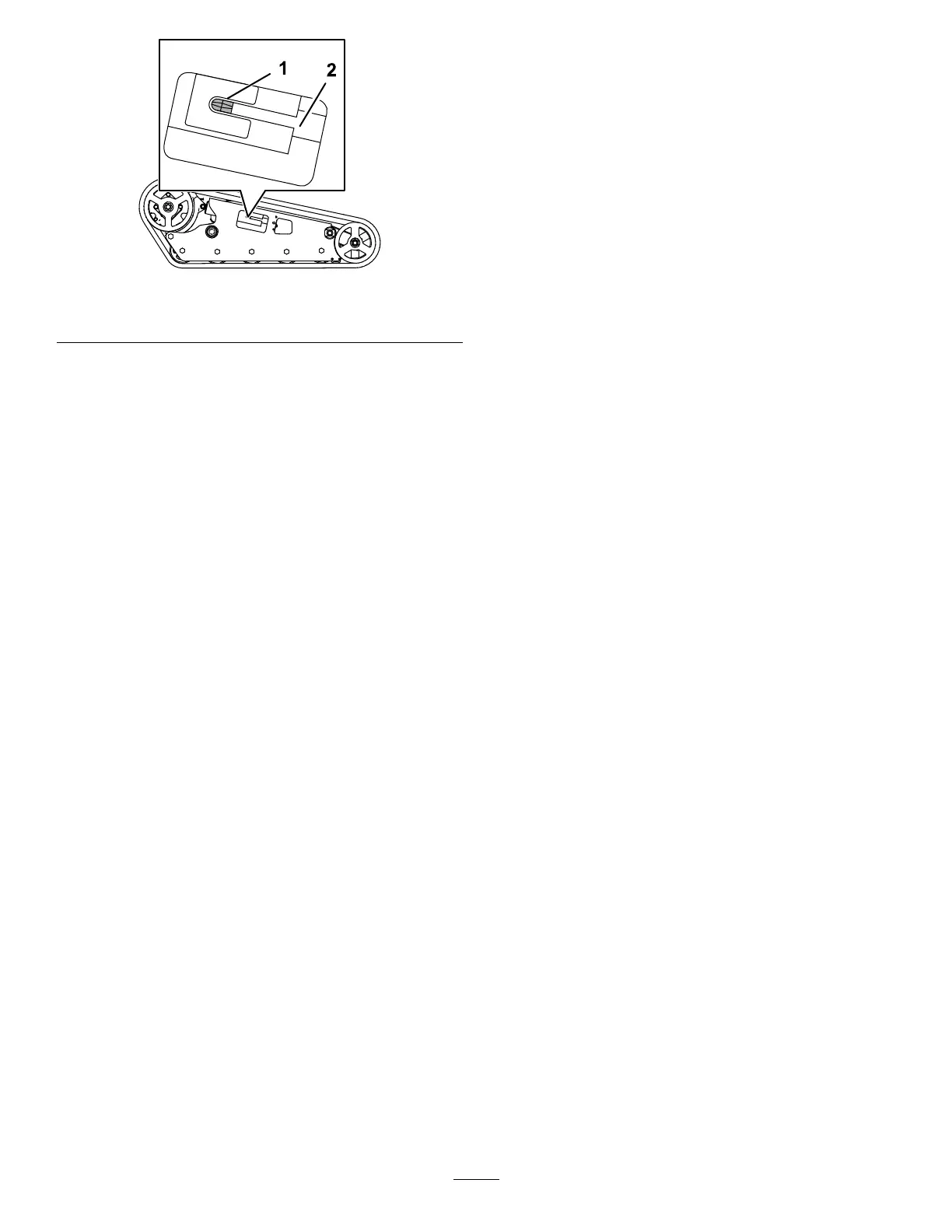

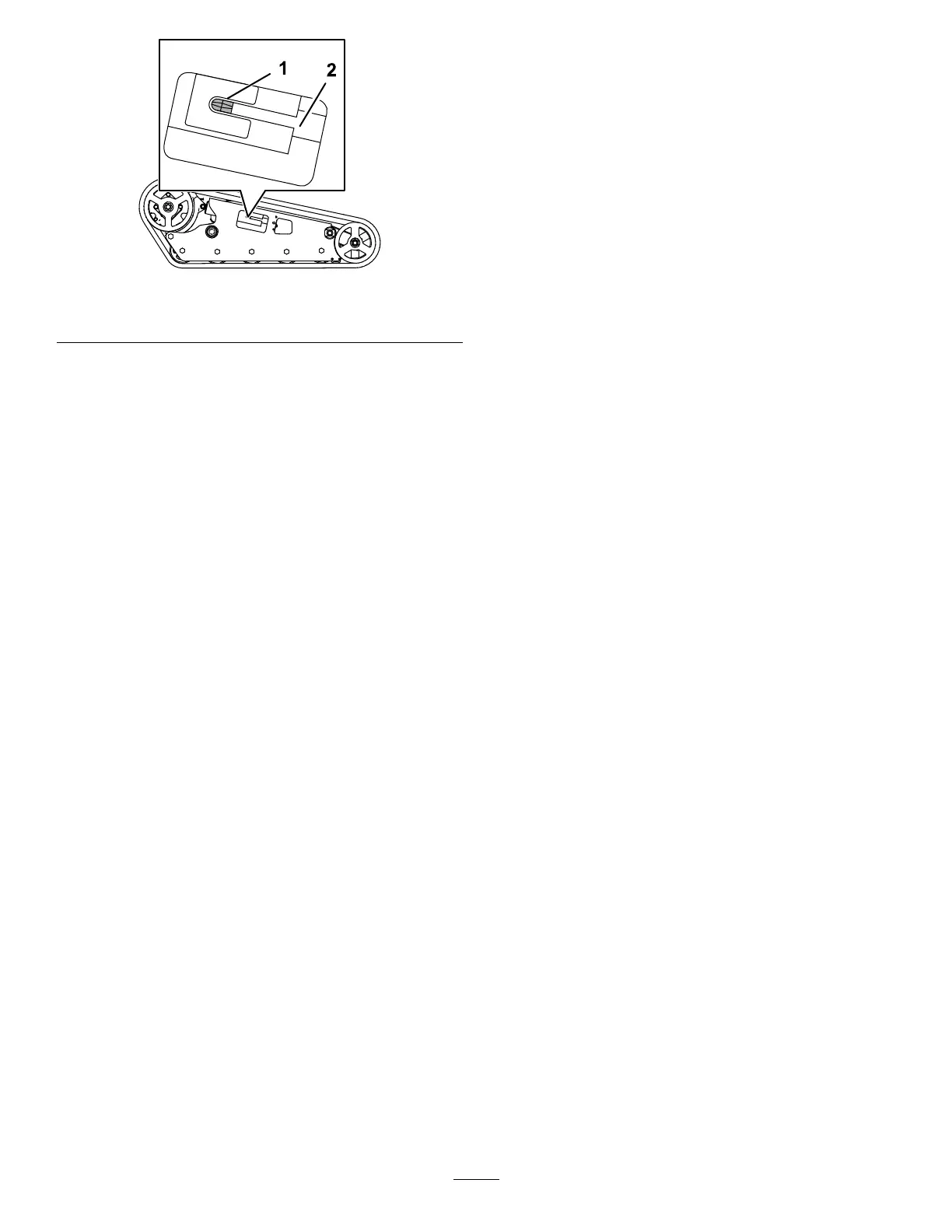

g203963

Figure67

1.Tensionnut2.Tensionscrew

16.Aligntheclosestnotchinthetensionscrewto

thelockingboltholeandsecurethescrewwith

thelockingboltandnut.

17.Torquetherearboltto108to122N∙m(80to

90ft-lb).

18.Lowerthemachinetotheground.

19.Repeattheproceduretoreplacetheothertrack.

20.Drivethemachine,thenparkthemachineona

levelsurface,engagetheparkingbrake,shutoff

theengine,andremovethekey.

21.Verifythatthetensionblockisbottomedout.

Note:Thetracktensionloosensaftersome

use.

22.Adjustthetracktensionsothatthetensionblock

alignswiththegreenguideonthedecaloris1.3

cm(1/2inch)awayfromtherearofthetension

tubeslot;refertoAdjustingtheTrackT ension

(page39).

CoolingSystem

Maintenance

CoolingSystemSafety

•Swallowingenginecoolantcancausepoisoning;

keepoutofreachfromchildrenandpets.

•Dischargeofhot,pressurizedcoolantortouching

ahotradiatorandsurroundingpartscancause

severeburns.

–Alwaysallowtheenginetocoolatleast15

minutesbeforeremovingtheradiatorcap.

–Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

ServicingtheCooling

System

ServiceInterval:Beforeeachuseordaily—Clean

thescreen,oilcooler,andfrontof

theradiator(moreoftenindirtyor

dustyconditions).

Beforeeachuseordaily—Checkthecoolant

levelintheexpansiontank.

Every100hours—Checkthecoolingsystem

hoses.

Yearly—Changetheenginecoolant(Authorized

ServiceDealeronly).

CleaningtheRadiatorScreen

ServiceInterval:Beforeeachuseordaily

Removeanybuildupofgrass,dirtorotherdebrisfrom

theradiatorscreenwithcompressedair.

CheckingtheEngine-Coolant

Level

Thecoolingsystemislledwitha50/50solutionof

waterandpermanentethylene-glycolantifreeze.

1.Parkthemachineonalevelsurface,lowerthe

loaderarms,engagetheparkingbrake,and

shutofftheengine.

2.Removethekeyfromthekeyswitchandallow

theenginetocool.

3.Checkthecoolantlevelintheexpansiontank

(Figure68).

Thecoolantlevelshouldbeatorabovethemark

onthesideofthetank.

43

Loading...

Loading...