DriveSystem

Maintenance

ServicingtheTracks

ServiceInterval:Aftertherst8hours—Checkand

adjustthetracktension.

Aftertherst50hours—Checkandadjustthe

tracktension.

Every50hours—Checkandadjustthetrack

tension.

Beforeeachuseordaily—Cleanthetracksand

checkforexcessivewearandpropertension.

CleaningtheTracks

1.Parkthemachineonalevelsurfaceandengage

theparkingbrake.

2.Withthebucketinstalledandangleddownward,

loweritintothegroundsothatthefrontofthe

tractionunitliftsoffthegroundafewcentimeters

(inches).

3.Shutofftheengineandremovethekey.

4.Usingawaterhoseorpressurewasher,remove

dirtfromeachtracksystem.

Important:Ensurethatyouusehigh-pressure

watertowashonlythetrackarea.Donotuse

ahigh-pressurewashertocleantherestofthe

tractionunit.Donotusehighpressurewater

betweenthedrivesprocketandthetractionunitor

youmaydamagethemotorseals.High-pressure

washingcandamagetheelectricalsystemand

hydraulicvalvesordepletegrease.

Important:Ensurethatyoufullycleanthe

roadwheels,frontwheel,rearwheel,anddrive

sprocket.Theroadwheelsshouldrotatefreely

whenclean.

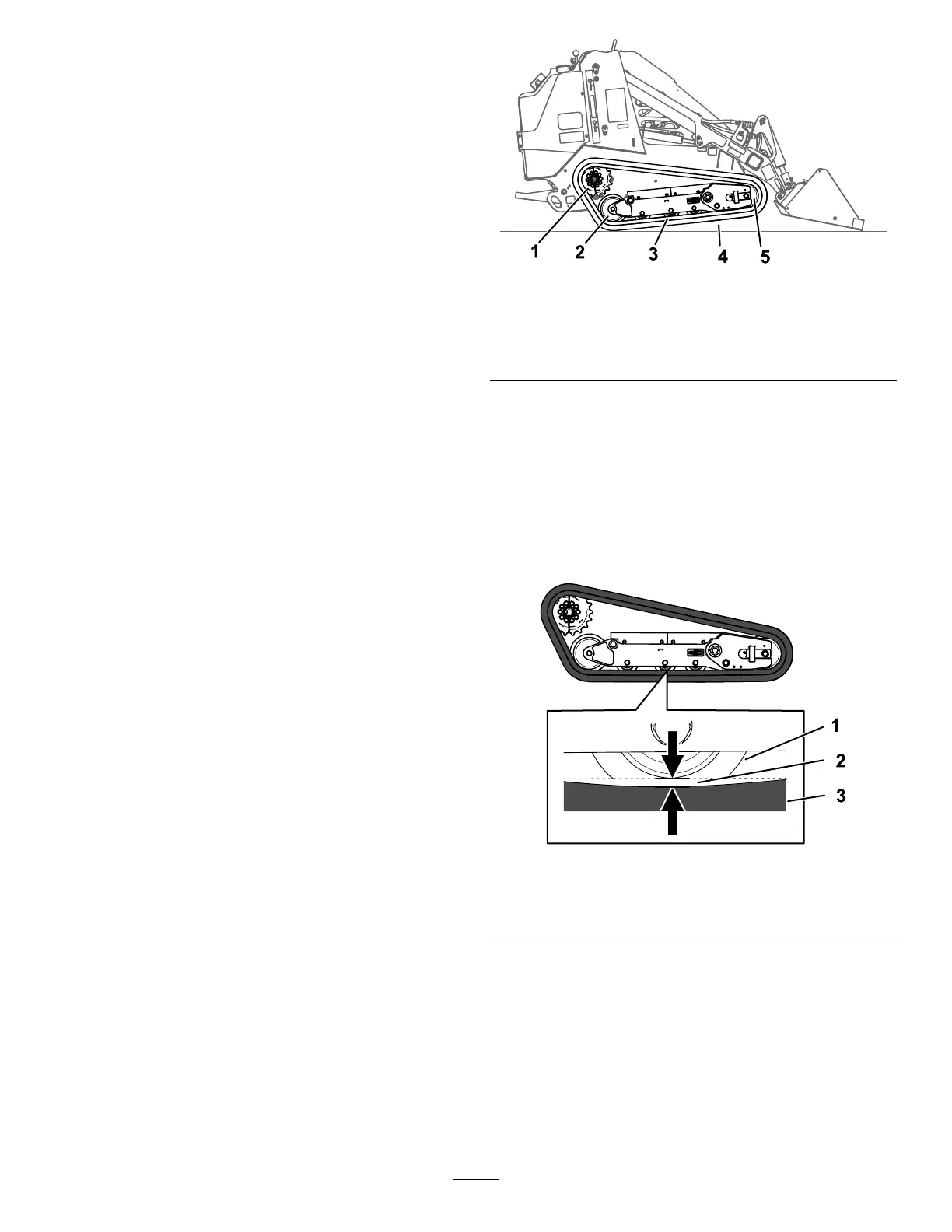

g366284

Figure54

1.Sectionaldrivesprocket

4.Track

2.Rearwheel5.Frontwheel

3.Roadwheel(4)

CheckingandAdjustingtheTrack

Tension

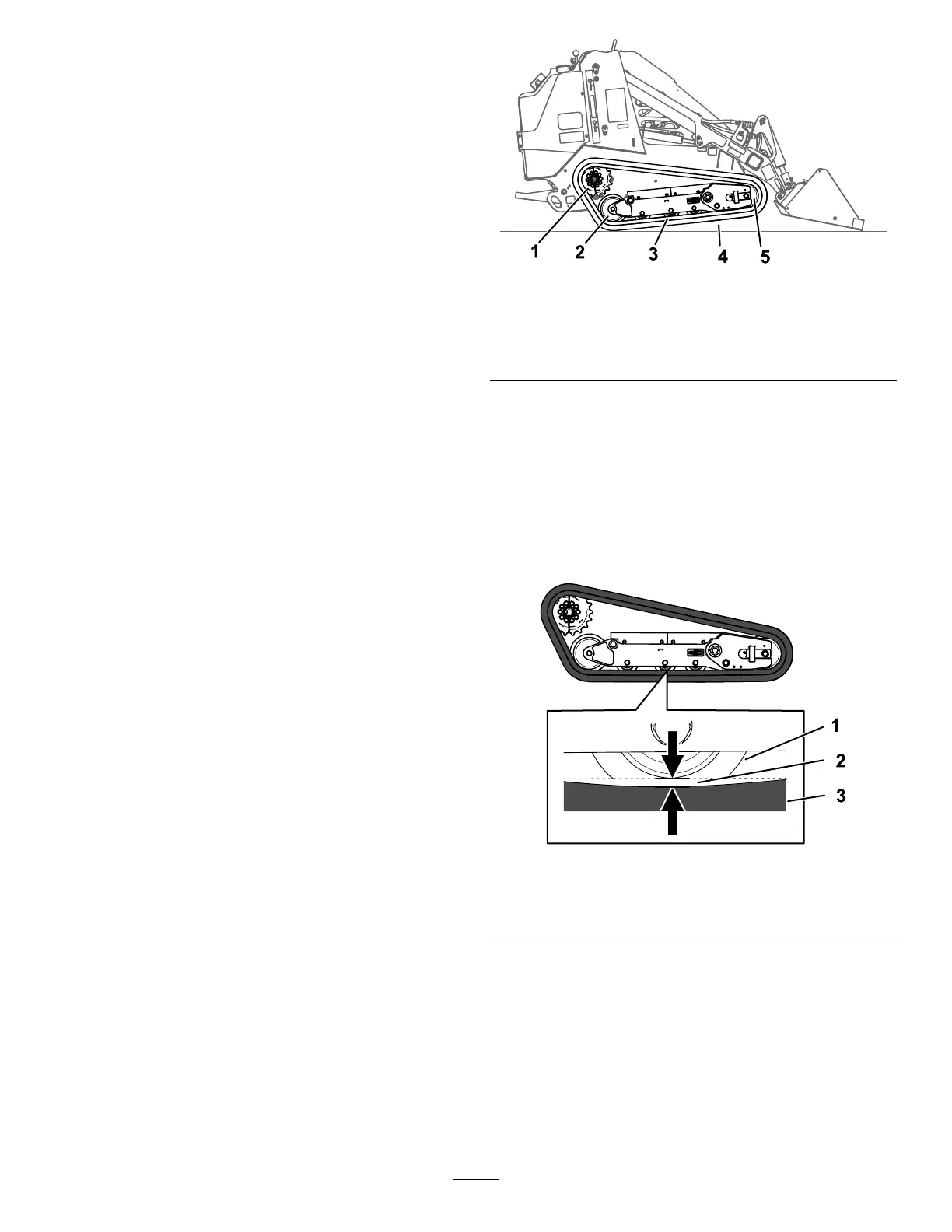

Lift/support1sideofthemachineandusingthe

weightofthetrack,verifythatthegapbetweenthe

bottomofthelipoftheroadwheelandthetrackis

13mm(1/2inch).Ifitisnot,adjustthetracktension

usingthefollowingprocedure.

g366296

Figure55

1.Roadwheel3.Track

2.13mm(1/2inch)gap

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Raisethesideofthemachinethatyouare

adjustingsothatthetrackisofftheground.

41

Loading...

Loading...