- 9 -

requirements, using as reference the type SHELL

LUTEM OIL ECO. THE MINIMUM PERCENTAGE

OF OIL DILUTED IN WATER IS 8 - 10 %.

6.7 Oil disposal

The disposal of these products is controlled by strict

regulations. Please see the Chapter on "Machine

dimensions Transport - Installation" in the section

on Dismantling.

6.8 The gear box

The gear box requires periodic changing of oil. The

oil must be changed by the first 6 months of a new

machine and every year thereafter.

To change the gear box oil

- Disconnect the machine from the power source.

- Raise the saw arm to vertical position

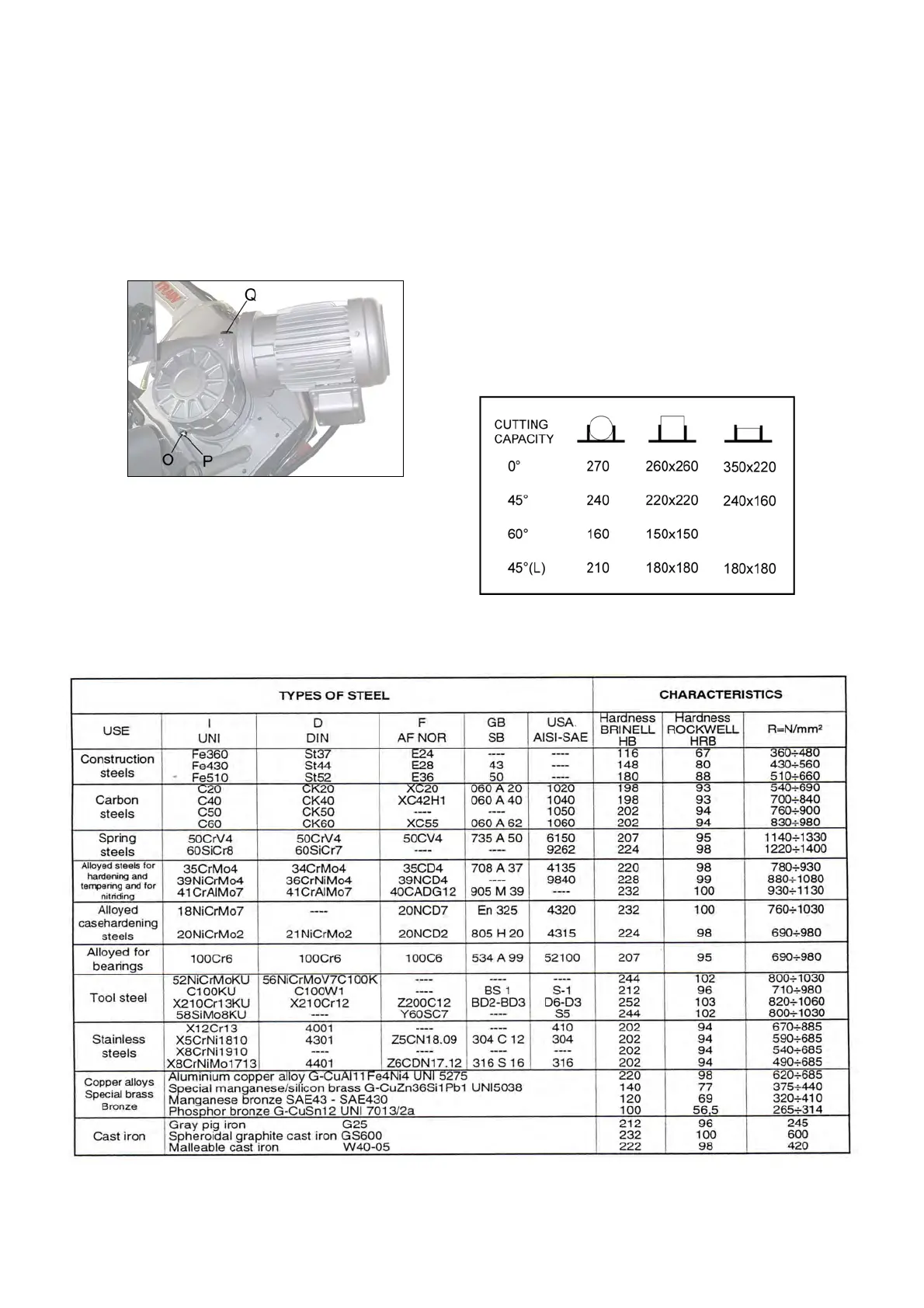

- Release the drain hold (O) to draw off gear oil by

loosening the hex socket screw (P).

- Replace the screw (P) after oil completely flows

off.

- Place the saw arm back to horizontal position.

- Fill Gear box with approximately .3 liter of gear oil

through the hole of the vent screw (Q)

For reference, use SHELL type gear oil or Mobile gear

oil #90.

6.9 Special maintenance

Special maintenance must be conducted by skilled

personnel. We advise contacting your nearest dealer

and/or importer. Also the reset of protective and safety

equipment and devices (of the reducer), the motor, the

motor pump, and other electrical components requires

special maintenance.

7 TECHNICAL CHARACTERISTICS

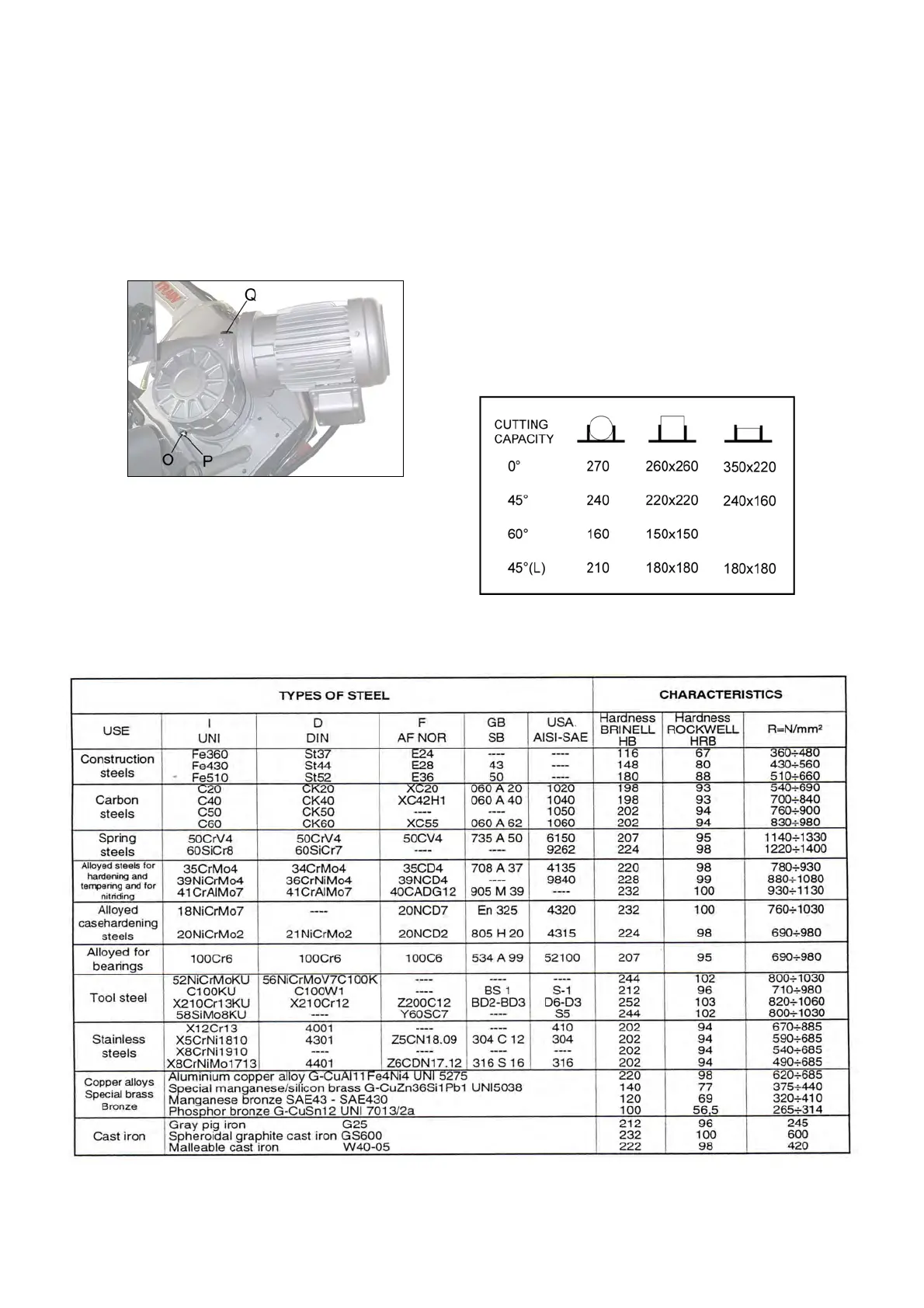

7.1 Table of cutting capacity and technical details

Loading...

Loading...