- 6 -

BLADE CUTTING DIRECTION

- Press trigger switch (J) to start operation.

- If cutting pipe with thin walls, reduce the saw arm

descent rate by adjusting the flow control valve (A)

- Press the emergency push button (K) down to shut

off all functions. To release the emergency push

button rotate the mushroom shaped button (K)

clock-wise. The button will pop up and then the

cutting cycle can be restarted.

- In general, start cuts by slightly turning hydraulic flow

control valve (A) counter-clockwise from 2 to 3 to

control the saw arm descent rate. If the arm

descends too quickly, turn the hydraulic flow

regulation valve (B) clockwise all the way back to stop

its descent. A saw arm dropping too quickly can

cause the blade to stall on the work piece and the

machine will shut off. Push down on emergency

push button (K) to immediately stop all machine

functions.

C1 C2

B. Auto cutting operation

- Close the hydraulic flow control valve (A) by turning

the valve clockwise all the way to the end.

- Raise the saw arm.

- Lift the spring knob (S) to release the pin from its slot.

This will free the fork handle (C). Move the handle

to the auto position (C2). Lift the spring knob (S)

and secure its pin into its slot.

- Use manual/auto selector (D) to select auto.

- Select cutting speed by turning speed selector (F).

Turtle is low speed, rabbit is high speed, and ‘O’ is

neutral.

- Turn main connect switch (G) to the ON position.

Check that the indicator light (H) is on.

- Load work piece and clamp it properly.

- Press start/reset button (E) to start machine. Check

that the blade is running in the correct direction.

- Slightly pull the saw arm down to get rid of air

bubbles from the hydraulic cylinder.

- Adjust hydraulic flow control valve (A) by slightly

turning the valve counter-clockwise to let saw arm

descend and start cutting.

- Press the emergency push button (K) down to shut

off all functions. To release the emergency shut off

rotate emergency push button (K) clock-wise. The

button will pop up and then the cutting cycle can be

restarted.

- In general, start cuts by slightly turning hydraulic flow

control valve (A) counter-clockwise from 2 to 3 to

control the saw arm descent rate. If the arm

descends too quickly, turn hydraulic flow regulation

valve (B) clockwise all the way back to stop its

descent. A saw arm dropping too quickly can cause

the blade to stall on the work piece and the machine

will shut off. Push down on emergency push button

(K) to immediately stop all machine functions.

-

4 ADVICE ON USING YOUR BANDSAW

4.1 Recommendations and advice for using the

machine

The machine has been designed to cut metal building

materials, with different shapes and profiles, used in

workshops, turner's shops and general mechanical

structural work,

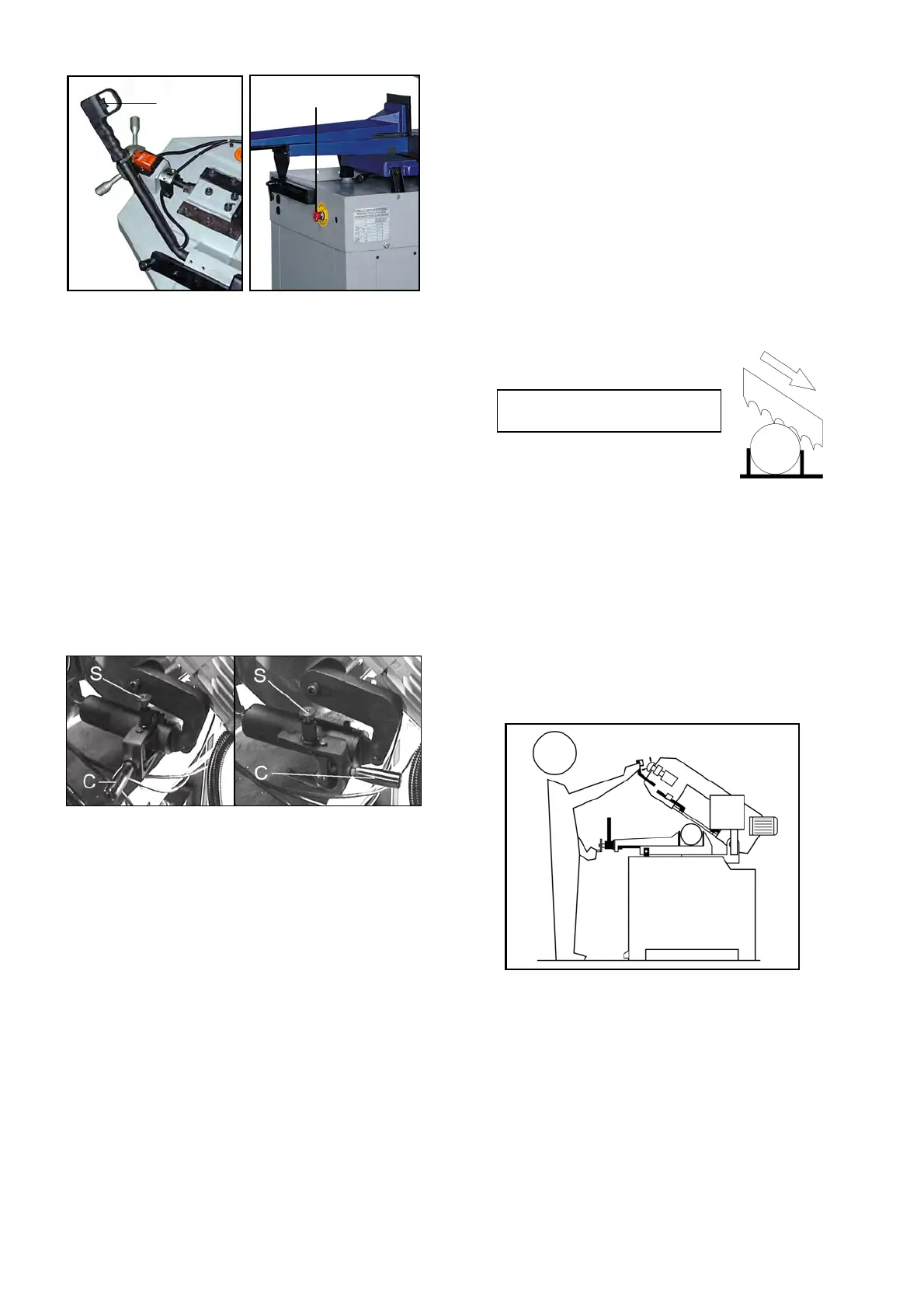

Only one operator is needed to use the machine, that

must stand as shown in the picture.

- Before starting each cutting operation, ensure that

the part is firmly clamped in the vice and that the end

is suitably supported.

- These figures below show examples of suitable

clamping of different section bars, bearing in mind the

cutting capacities of the machine in order to achieve a

good efficiency and blade durability.

K

J

Loading...

Loading...