- 7 -

- Do not use blades of a different size from those

stated in the machine specifications.

- If the blade gets stuck in the cut, release the running

button immediately, switch off the machine, open the

vice slowly, remove the part and check that the blade

or its teeth are not broken. If they are broken, change

the tool.

- Before carrying out any repairs on the machine,

consult the dealer.

5 ADJUSTING YOUR MACHINE

5.1 Blade tension assembly

The ideal tension of the blade is achieved rotating the

handwheel until it the microswitch, that actuates the

operation of the machine is actuated

WARNING: the position of this switch is factory set

during inspection, after having tightened the blade on

the lengthening values indicated by its manufacturer as

per specific dimensions set with the help of a special

instrument. When replacing the blade, if the

thickness and the width differ, it will be necessary to

correct the projection of the switch. For this purpose

we suggest to strictly select blades having the same

features as mounted originally.

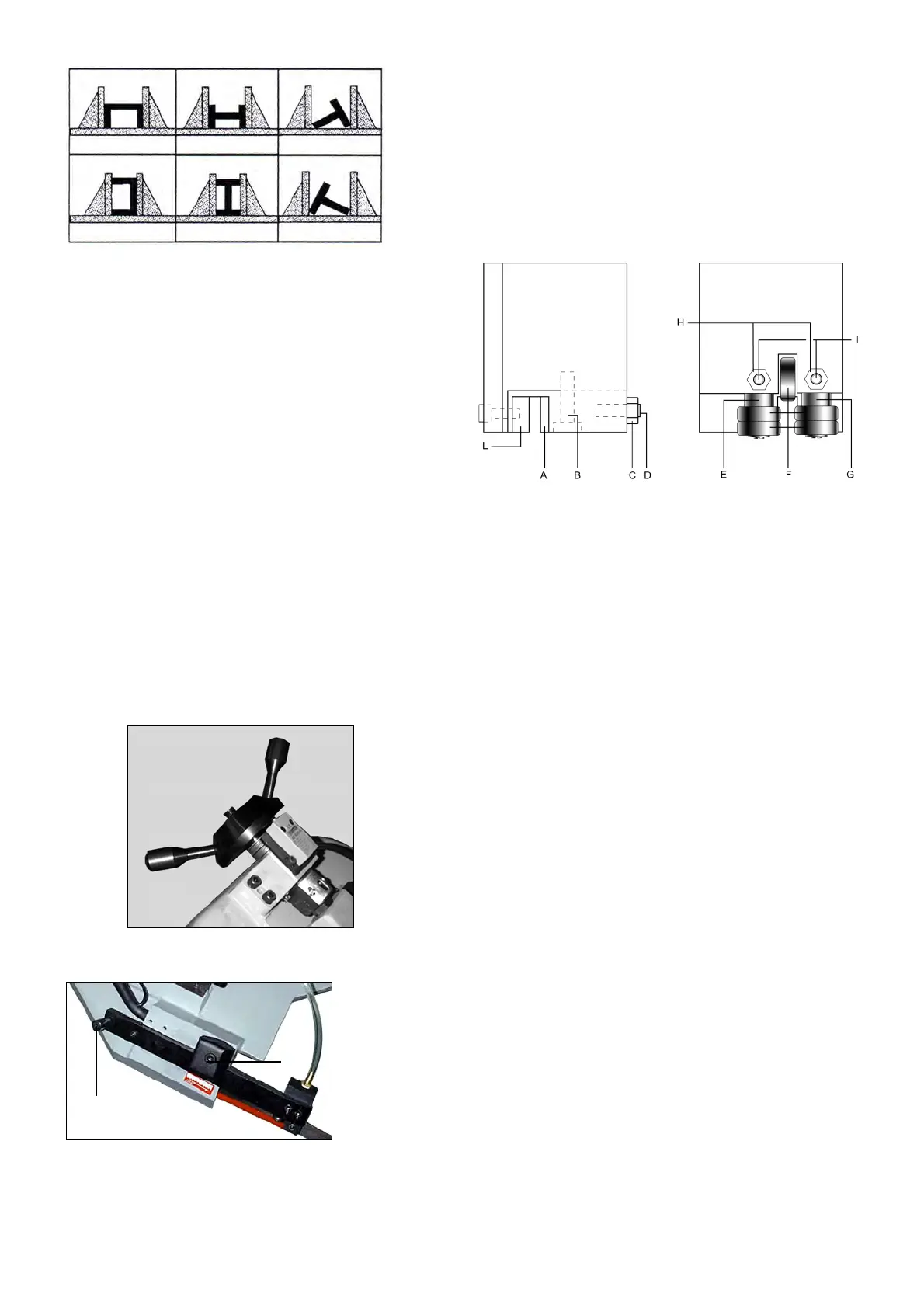

5.2 Adjusting the blade guide

- Disconnect the machine from the power source.

- Use a Hex. Wrench to loosen Hex. Socket screw (A)

on the square lock plate.

- Hold the handle (B) and slide blade guide block as

close as possible to the material without interfering

with the cut

- Tighten the Hex. Socket screw (A).

- Reconnect the machine to power source.

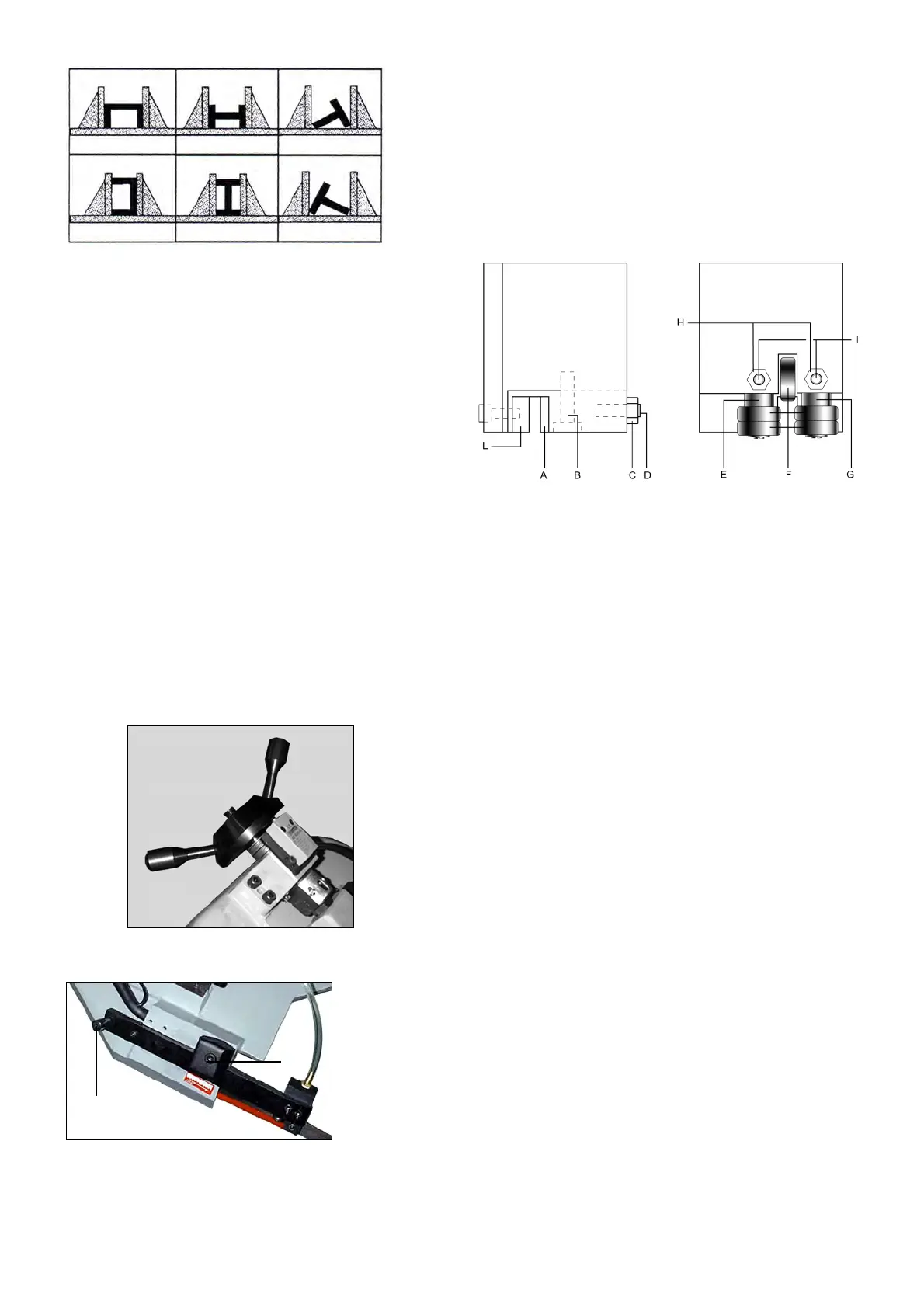

Blade guide blocks

The blade is guided by means of adjustable pads set in

place during inspection as per the thickness of the

blade with minimum play as shown in the figure.

In case the blade needs to be replaced, make sure to

always install 0.9mm thick blades for which the blade

guide pads have been adjusted. In the case of toothed

blades with different thicknesses adjustment should be

carried out as follows:

- Loosen nut (C), screw (B) and loosen dowel (D)

widening the passage between the pads.

- Loosen the nuts (H) and the dowels (I) and rotate the

pins (E - G) to widen the passage between the

bearings (F).

- To mount the new blade: place the pad (A) on the

blade, loosening the dowel, allow a play of 0.04 mm

for the sliding of the toothed blade, lock the relative

nut and screw (B), Rotate the pins (E - G) until the

bearings rest against the blade as indicated in the

figure and then secure the dowels (I) and nut (H).

- Make sure that between the blade and the upper

teeth of the pad (L) this is at least 0.2 - 0.3 mm of

play; if necessary, loosen the screws that fasten the

blocks and adjust accordingly.

BEFORE PERFORMING THE FOLLOWING

OPERATIONS, THE ELECTRIC POWER SUPPLY

AND THE POWER CABLE MUST BE COMPLETELY

DISCONNECTED.

5.3Changing the blade

To change the blade:

- Lift the saw arm.

- Loosen the blade with the handwheel, remove the

mobile blade-guard cover, open the flywheel guards

and remove the old blade from the flywheels and the

blade guide blocks.

- Assemble the new blade by placing it first between

the pads and then on the race of the flywheels,

paying particular attention to the cutting direction of

the teeth.

- Tension the blade and make sure it perfectly fits

inside the seat of the flywheels.

B

A

Loading...

Loading...