- 8 -

- Assemble the mobile blade-guide end, the flywheel

guard, and fasten it with the relative knobs. Check

that the safety microswitch is activated otherwise

when electric connection will be restored the machine

will not start.

5.4 Adjusting the blade to the flywheels

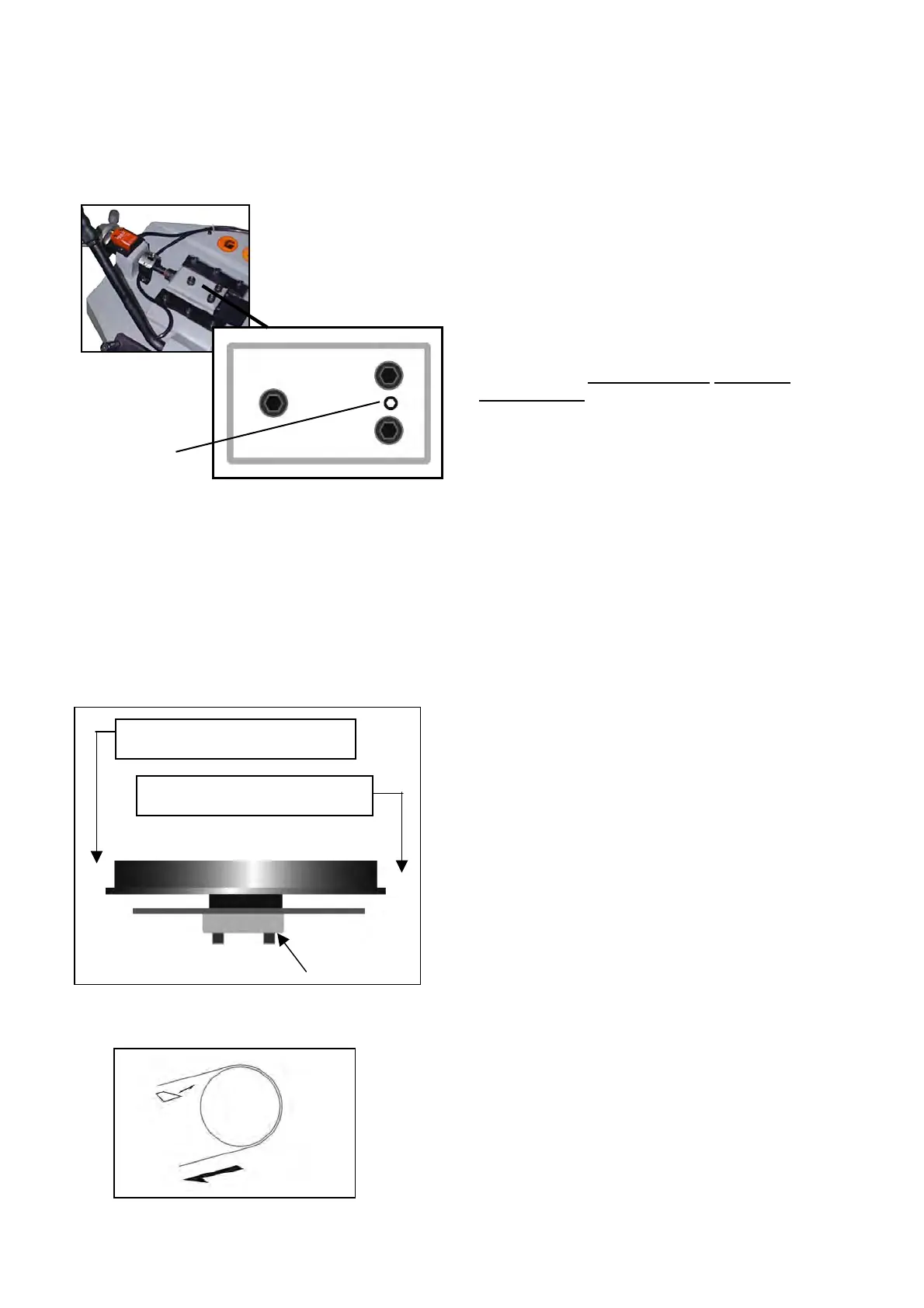

1. Loosen the hex nut screws A, B, and C.

2. Use an Allen wrench on setscrew D to adjust the

tilt of the flywheel.

-Turning the setscrew, D clockwise will tilt flywheel so

that the blade will ride closer to the flange.

-Turning the setscrew, D counter-clockwise will tilt the

flywheels so the blade will ride away from the flange.

If the blade rides away too far then it will come off.

After the adjustment is finished, fasten the hex nut

screws in this order: A, B, and C.

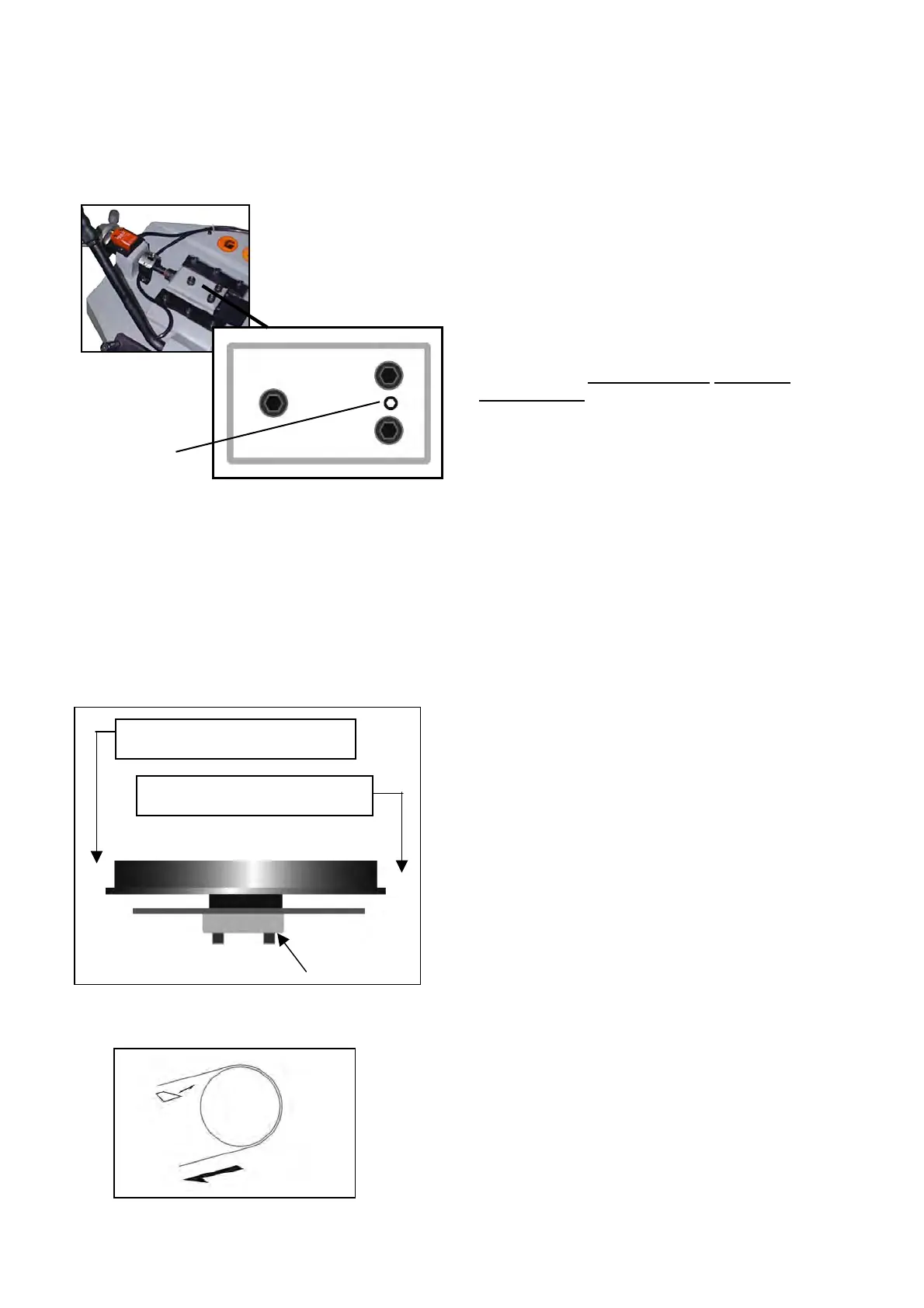

Checking the adjustment of the blade

Use a strip of scrap paper and slide it between the

blade and the flywheel while it is running.

-if the paper is cut then the blade is riding too close to

the flange. Re-adjust.

-if you notice that the blade is riding away from the

flange. Then re-adjust.

WARNING: Always assemble blades having

dimensions specified in this manual and for which the

blade guide heads have been set; otherwise, see

chapter on "Description of the operating cycle" in the

section Starting-up.

6 ROUTINE AND SPECIAL

MAINTENANCE

THE MAINTENANCE JOBS ARE LISTED BELOW,

DIVIDED INTO DAILY, WEEKLY,

MONTHLY AND

SIX-MONTHLY

INTERVALS. IF THE FOLLOWING

OPERATIONS ARE NEGLECTED, THE RESULT

WILL BE PREMATURE WEAR OF THE MACHINE

AND POOR PERFORMANCE.

6.1 Daily maintenance

- General cleaning of the machine to remove

accumulated shavings.

- Clean the lubricating coolant drain hole to avoid

excess fluid.

- Top off the level of lubricating coolant.

- Check blade for wear.

- Rise of saw frame to top position and partial

slackening of the blade to avoid useless yield stress.

- Check functionality of the shields and emergency

stops.

6.2 Weekly maintenance

- Thorough cleaning of the machine to remove

shavings, especially from the lubricant fluid tank.

- Removal of pump from its housing, cleaning of the

suction filter and suction zone.

- Clean the filter of the pump suction head and the

suction area.

- Use compressed air to clean the blade guides (guide

bearings and drain hole of the lubricating cooling).

- Cleaning flywheel housings and blade sliding

surfaces on flywheels.

6.3 Monthly maintenance

- Check the tightening of the motor flywheel screws.

- Check that the blade guide bearings on the heads are

perfect running condition.

- Check the tightening of the screws of the gear motor,

pump, and accident protection guarding.

6.4 Six-monthly maintenance

- Continuity test of the equipotential protection circuit.

6.5 Maintenance of other machine parts

The worm drive gearbox mounted on the machine is

maintenance-free guaranteed by its manufacture.

6.6 Oils for lubricating coolant

Considering the vast range of products on the market,

the user can choose the one most suited to their own

TOP

A

C

B

Setscrew D

A Tilt in this direction will cause the

l

ri

w

r

h

fl

n

A Tilt in this direction will cause the

l

ri

w

fr

m

h

fl

n

Top view

Set screw D

paper

Blade direction

flywheel

Loading...

Loading...