- 11 -

8.7 Blade type

They differ essentially in their constructive

characteristics, such as:

- Shape and cutting angle of tooth

- Pitch

- Set

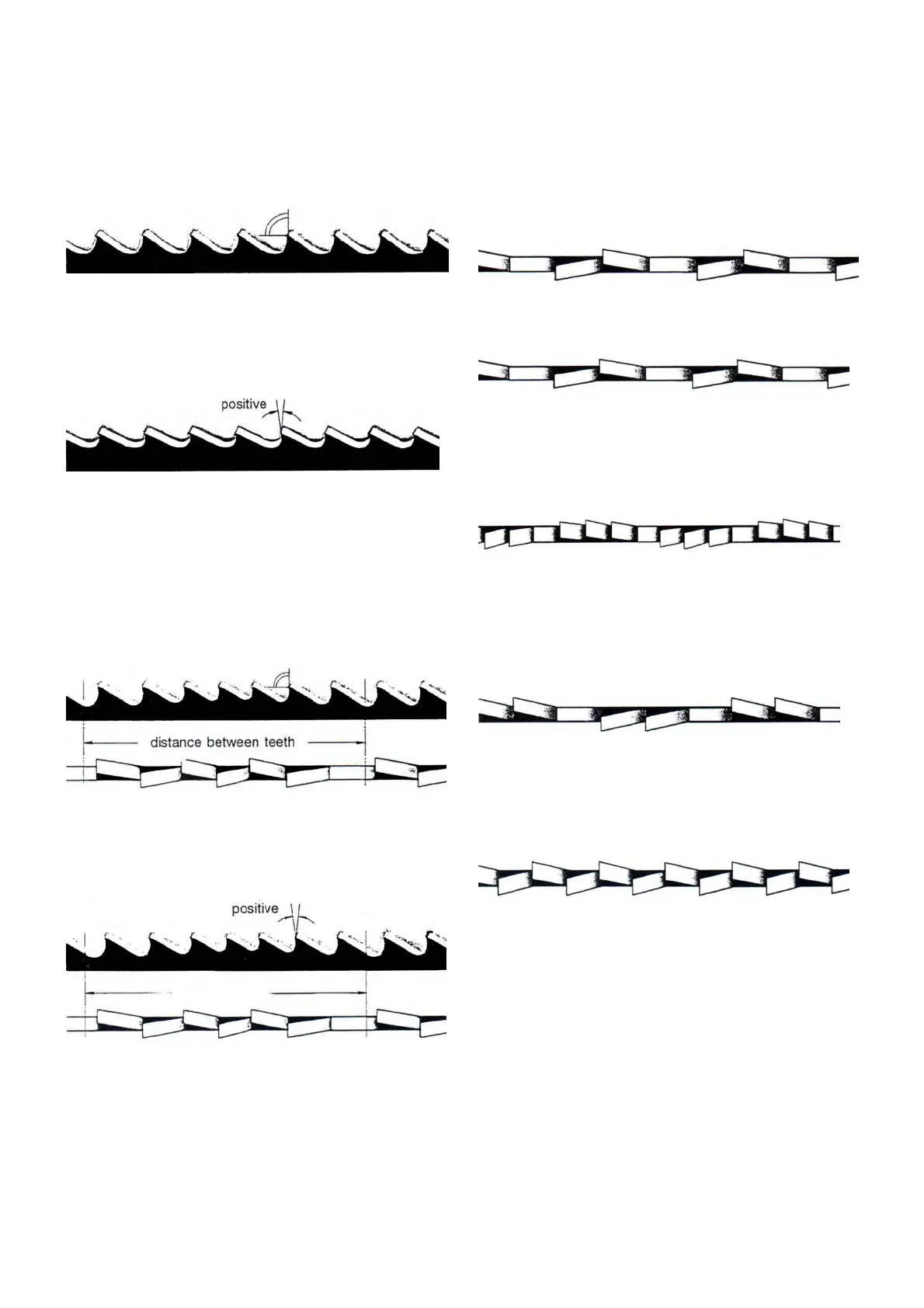

Shape and angle of tooth

REGULAR TOOTH: Oº rake and constant pitch.

Most common form for transversal or inclined cutting of

solid small and average cross-sections or pipes, in

laminated mild steel and gray iron or general metal.

POSITIVE RAKE TOOTH: 9º - 10º positive rake and

constant pitch.

Particular use for crosswise or inclined cuts in solid

sections or large pipes, but above all harder materials

(highly alloyed and stainless steels, special bronze and

forge pig iron).

COMBO TOOTH: pitch varies between teeth and

consequently varying teeth size and varying gullet

depths. Pitch varies between teeth, which ensures a

smoother, quieter cut and longer blade life owing to the

lack of vibration.

Another advantage offered in the use of this type of

blade in the fact that with an only blade it is possible to

cut a wide range of different materials in size and type.

COMBO TOOTH: 9º - 10º positive rake.

This type of blade is the most suitable for the cutting of

section bars and large and thick pipes as well as for

the cutting of solid bars at maximum machine capacity.

Available pitches: 3-4/4-6.

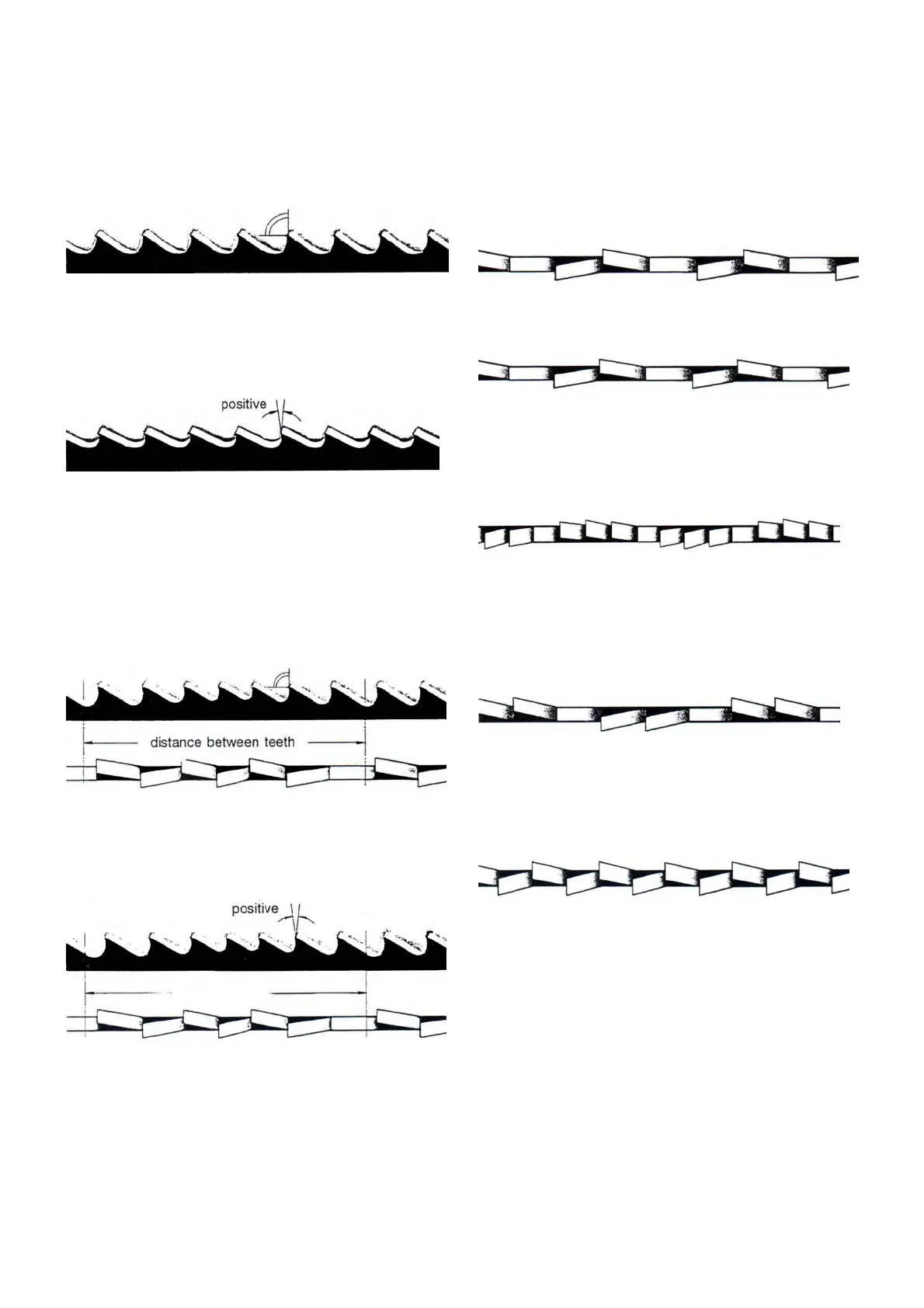

SETS

Saw teeth bent out of the plane of the saw body,

resulting in a wide cut in the workpiece.

REGULAR OR RAKER SET: Cutting teeth right and

left, alternated by a straight tooth.

Of general use for materials with dimensions superior

to 5 mm. Used for the cutting of steel, castings and

hard nonferrous materials.

WAVY SET: Set in smooth waves.

This set is associated with very fine teeth and it is

mainly used for the cutting of pipes and thin section

bars (from 1 to 3 mm).

ALTERNATE SET (IN GROUPS): Groups of cutting

teeth right and left, alternated by a straight tooth.

This set is associated with very fine teeth and it is used

for extremely thin materials (less than 1mm).

ALTERNATE SET (INDIVIDUAL TEETH): Cutting

teeth right and left.

This set is used for the cutting of nonferrous soft

materials, plastics and wood.

9 NOISE TESTS

The test was held under environmental noise levels of 65db. Noise measurements with the machine operating

unload was 71db. Noise level during the cutting of mild carbon steel was 73db.

NOTE: with the machine operating, the noise level will vary according to the different materials being processed.

The user must therefore assess the intensity and if necessary provide the operators with the necessary personal

protection, as required by Law 277/1991.

Loading...

Loading...