- 4 -

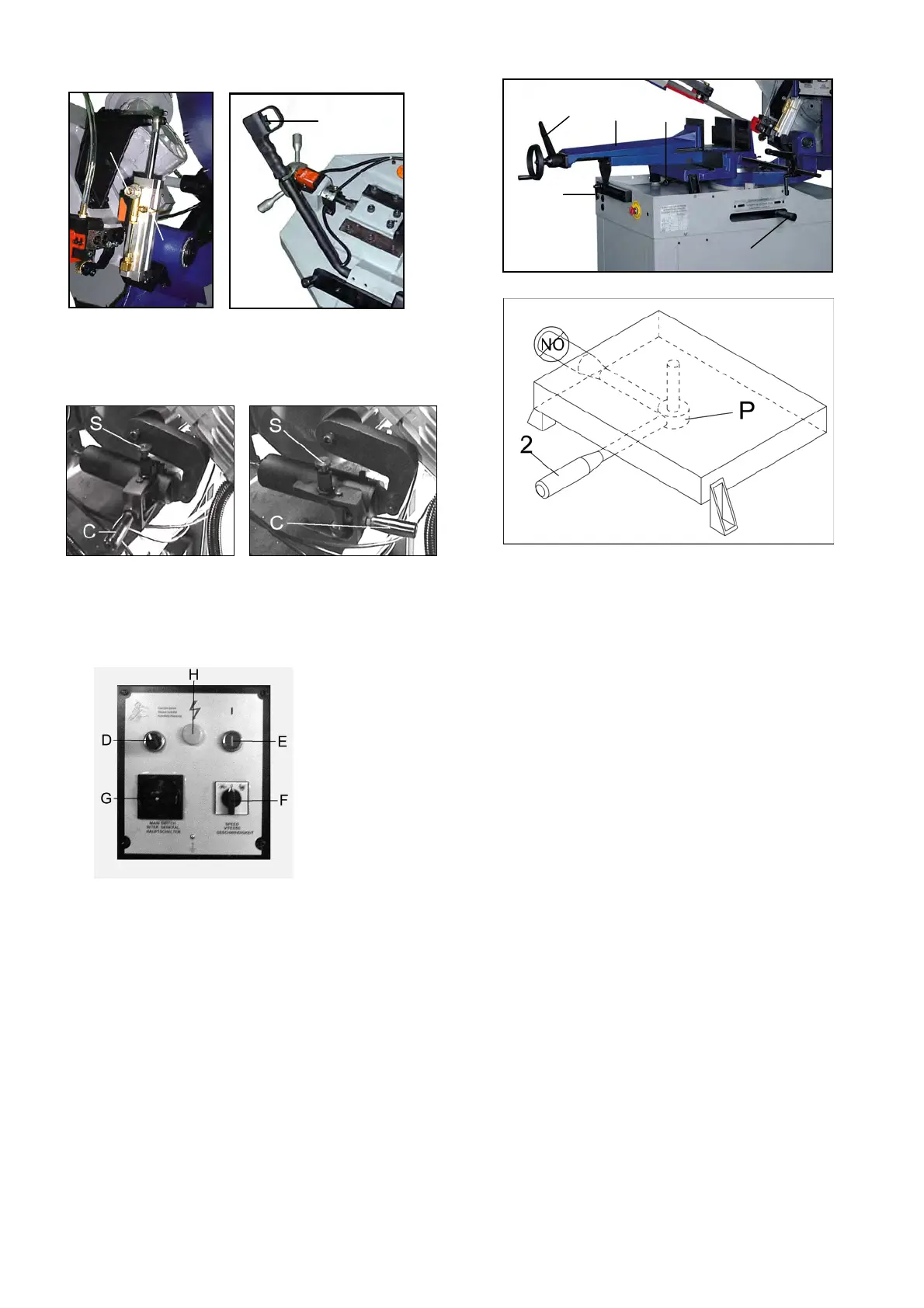

3.2 Controls

A. Hydraulic Flow control valve

B. Hydraulic regulation valve

J. Trigger Switch

C1 C2

C. Fork handle

S. Spring knob

C1. Manual position

C2. Auto position

D. Manual/Auto selector

E. Start/Reset push button

F. Speed selector

G. Main connect switch

H. Indicator light

K. Emergency push button

3.3 Vice adjustment

- The device does not require any particular

adjustment; in case of excess play of the sliding guide,

tighten slide screw more.

To move the vise in either direction, the vise jaw must

be unlocked at two points.

- Release the track support by turning handle (1)

counter-clockwise.

- Release the vise by moving the lever (2) to the left.

- The vise (5) may now be moved to right position (7)

or left position (6) by pushing it with one hand on the

vise and the other hand on the track handle (1).

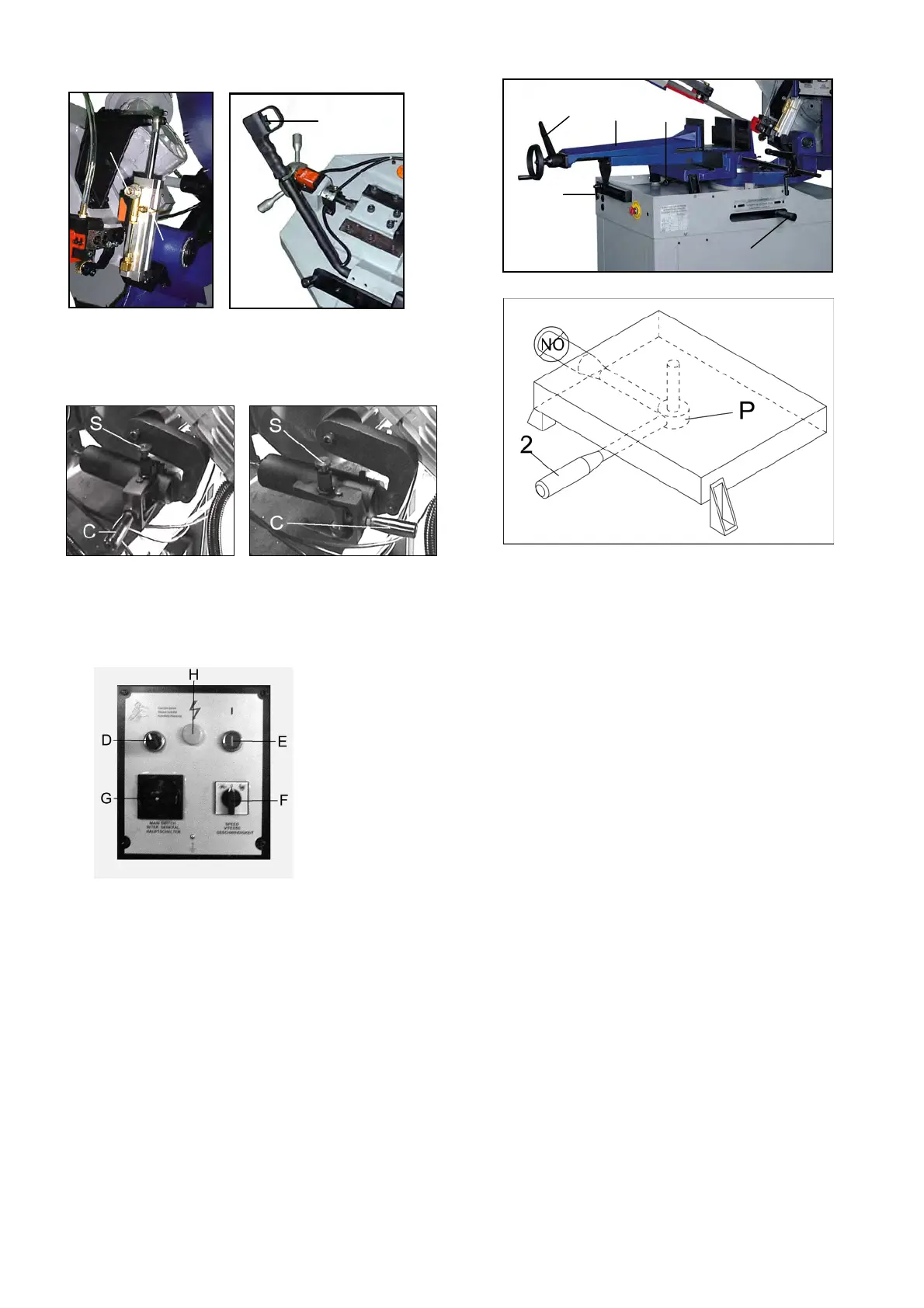

- Once in position, move the lever (2) to the right to

lock it into position. If the lever (2) is not between

the vise/bed mounts and facing the user, then the

vise will not be able to lock. If the vise lever (2) has

gone beyond or is obstructed by a vise/bed mount,

then use the following procedures.

- Adjust the lever (2) by grasping at the pivot point (P)

and lowering it, which may assist in the adjustment.

The lever can now be freely rotated into a more

convenient position. Some movement of the vise

jaw may be required. Raise the lever (2) then move

to the right to lock.

- Lock the track support (1) by turning handle

clockwise.

Clamping the Work Piece

- Place work piece between the jaws.

- Use the hand wheel to approach the vise jaws to the

work piece, leaving 3-4mm of space. Lock down work

piece and raise the lever (4). Push start button (E).

When the cutting cycle is finished, release vise by

lowering lever (4). Upon releasing the lever (4), the

vise jaw will open to the same distance that was set

initially. This allows for rapid loading of same size

material.

A

B

J

4

5

2

1

3

Loading...

Loading...