26

RT-SVX34V-EN

Installation Electrical

WARNING

Hazardous Voltage!

Failure to disconnect power before servicing could

result in death or serious injury.

Disconnect all electric power, including remote

disconnects before servicing. Follow proper lockout/

tagout procedures to ensure the power can not be

inadvertently energized. Verify that no power is

present with a voltmeter.

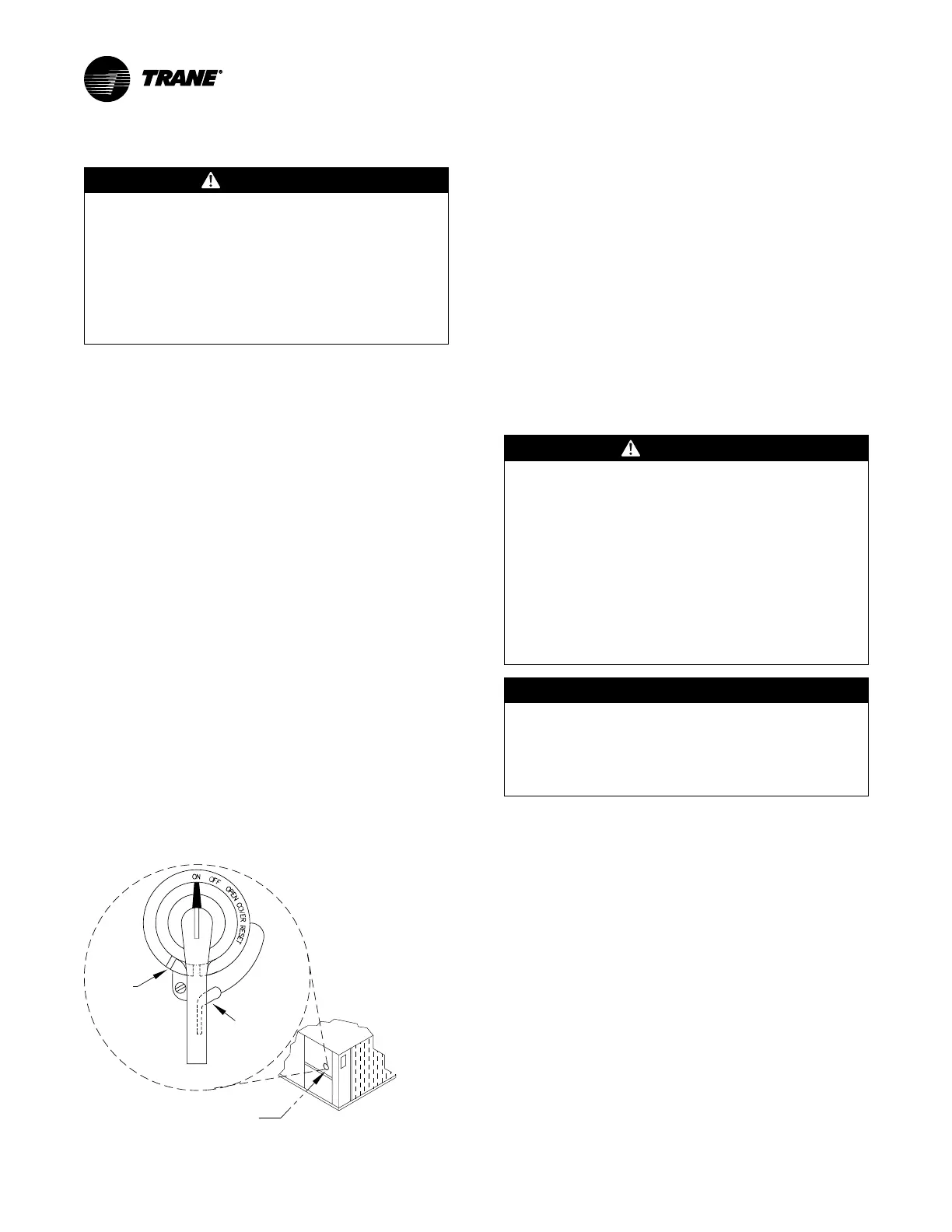

Disconnect Switch External

Handle (Factory Mounted

Option)

Units ordered with the factory mounted disconnect switch

come equipped with an externally mounted handle. This

allows the operator to disconnect power from the unit

without having to open the control panel door. The handle

location and its three positions are shown below;

• ON - Indicates that the disconnect switch is closed,

allowing the main power supply to be applied at the

unit.

• OFF - Indicates that the disconnect switch is open,

interrupting the main power supply at the unit.

• OPEN COVER/RESET - Turning the handle to this

position releases the handle from the disconnect

switch, allowing the control panel door to be opened.

Once the door has been opened, it can be closed with the

handle in any one of the three positions outlined above,

provided it matches the disconnect switch position. The

handle can be locked in the “OFF” position. While holding

the handle in the “OFF” position, push the spring loaded

thumb key, attached to the handle, into the base slot. Place

the lock shackle between the handle and the thumb key.

This will prevent it from springing out of position.

Figure 22. Disconnect switch

Disconnect switch

external handle

Locking

slot (OFF)

Locking

thumb key

C

ontr

o

l

Pa

n

e

l

Compressor Panel

An overall layout of the field required power wiring is

illustrated in . To insure that the unit supply power wiring is

properly sized and installed, follow the guidelines outlined

below.

Note: All field installed wiring must conform to NEC

guidelines as well as State and Local codes.

Verify that the power supply available is compatible with

the unit's name plate ratings for all components. The

available power supply must be within 10% of the rated

voltage stamped on the nameplate. Use only copper

conductors to connect the 3-phase power supply to the

unit.

Main Power Wiring

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury.

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements

for field wiring installation and grounding as

described in NEC and your local/state/national

electrical codes.

NOTICE

Use Copper Conductors Only!

Failure to use copper conductors could result in

equipment damage as the equipment was not

designed or qualified to accept other types of

conductors.

• Electrical service sizing data can be found on unit name

plate and in the product catalog. The electrical service

must be protected from over current and short circuit

conditions in accordance with NEC requirements.

Protection devices must be sized according to the

electrical data on the nameplate. Refer to “Electrical

Wire Sizing and Protection Device Equations,” p. 28 for

determining:

– The appropriate electrical service wire size based

on “Minimum Circuit Ampacity” (MCA),

– The “Maximum Over current Protection” (MOP)

device.

– The “Recommended Dual Element fuse size”

(RDE).

• If the unit is not equipped with an optional factory

installed Nonfused disconnect switch, a field supplied

disconnect switch must be installed at or near the unit

in accordance with the National Electrical Code (NEC

Loading...

Loading...