RT-SVX34V-EN

27

latest edition). Refer to DSS calculations “Electrical

Wire Sizing and Protection Device Equations,” p. 28 for

determining correct size.

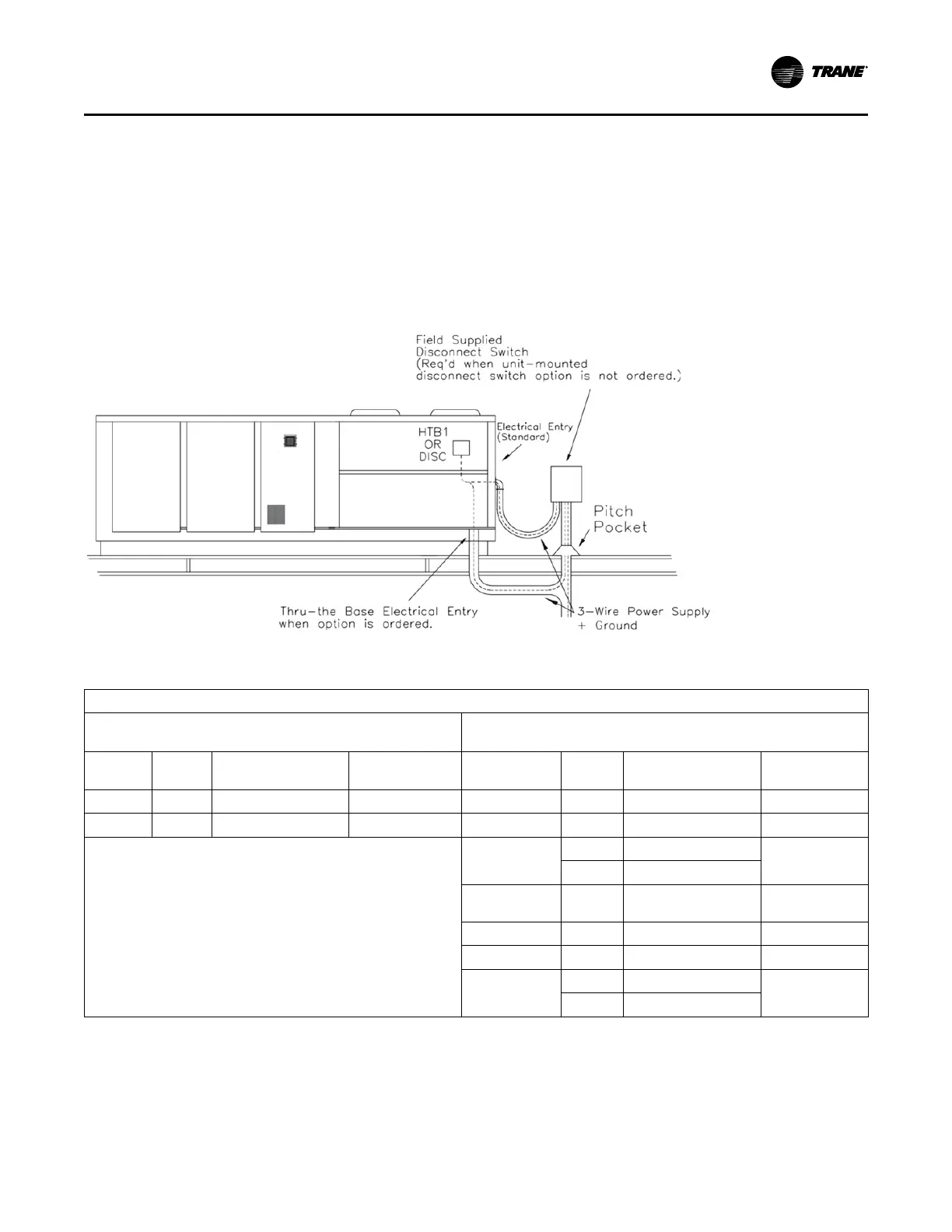

Location for the electrical service entrance is shown

in the unit dimensional drawings beginning with .

Complete the unit's power wiring connections onto

either the main terminal block HTB1, or the factory

mounted nonfused disconnect switch inside the unit

control panel.

Note: When the factory installed through-the-base

option is not used, the installing contractor is

required to seal any holes made in the base of

the unit to prevent water from leaking into the

building.

• Provide proper grounding for the unit in accordance

with local and national codes.

Figure 23. Typical field power wiring

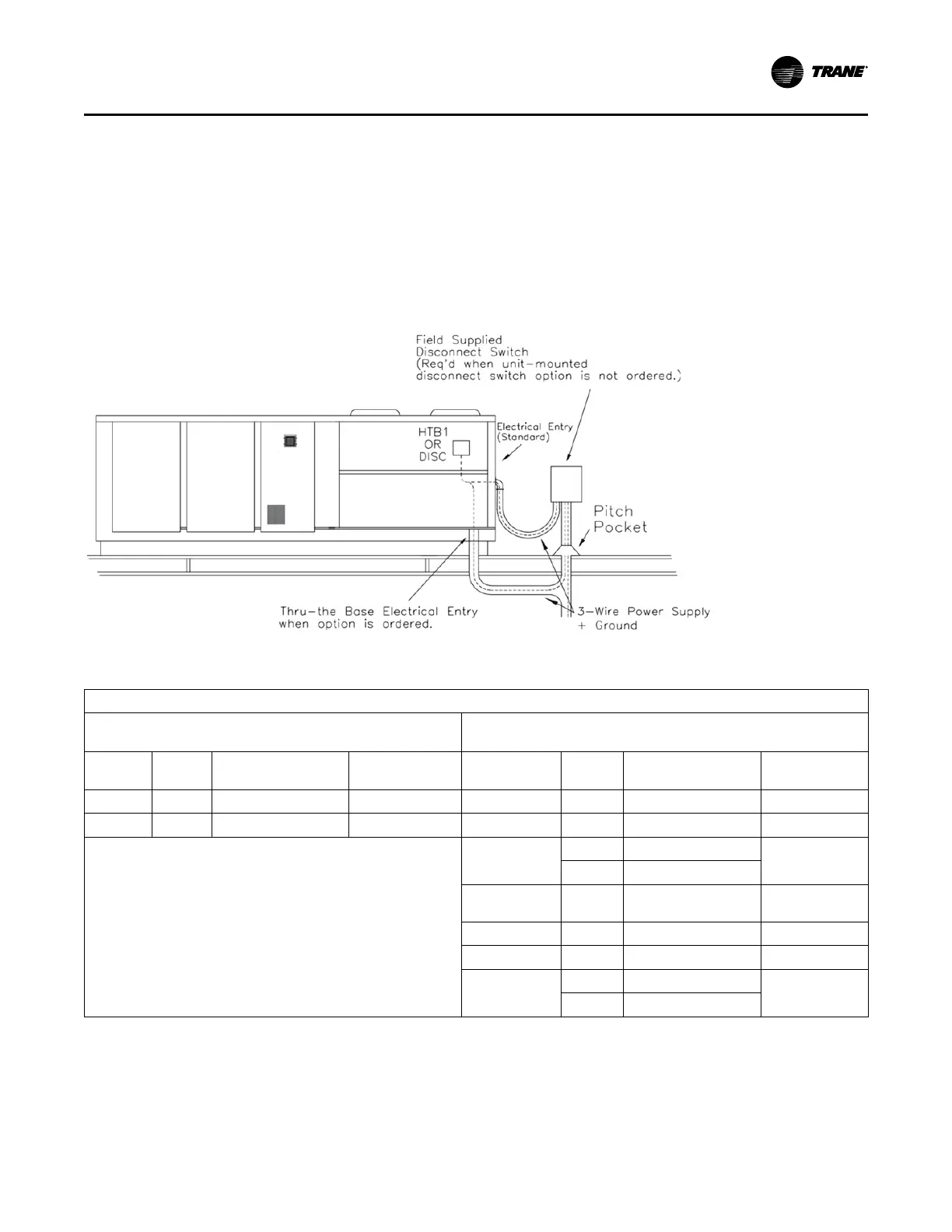

Table 7. Customer connection wire range

CUSTOMER CONNECTION WIRE RANGE

UNITS WITH MAIN POWER TERMINAL BLOCK ( ALL VOLTAGES)

UNITS WITH MAIN POWER DISCONNECT SWITCH/ CIRCUIT BREAKER (ALL

VOLTAGES)

BLOCK

SIZE

WIRE

QTY

CONNECTION WIRE

RANGE

USAGE DISCONNECT

WIRE

QTY

CONNECTOR WIRE

RANGE

USAGE

335 AMP 1 # 6 AWG - 400 MCM X<= 335 & Z<= 125 100 AMP 1 14 AWG - 3/0 x <= 100 & z <= 95

420 AMP 1 # 2 AWG - 600 MCM X<= 420 & Z<= 230 250 AMP 1 4 AWG - 350 MCM 100 < x <= 250

x = Max(MCA, 1.15*Heating amps, 1.15*Cooling amps) z = Heater amps +

SF amps + EF amps

400 AMP

1 1 AWG- 600 MCM

250 < x <= 400

2 2 AWG- 250 MCM

CIRCUIT

BREAKER

WIRE

QTY

CONNECTOR WIRE

RANGE

USAGE

100 AMP 1 14 AWG - 3/0 x <= 100 & z <= 95

250 AMP 1 4 AWG - 350 MCM 100 < x <= 250

400 AMP

1 1 AWG- 600 MCM

250 < x <= 400

2 2 AWG- 250 MCM

Installation Electrical

Loading...

Loading...