Installation

RT-SVX21P-EN 25

Ductwork

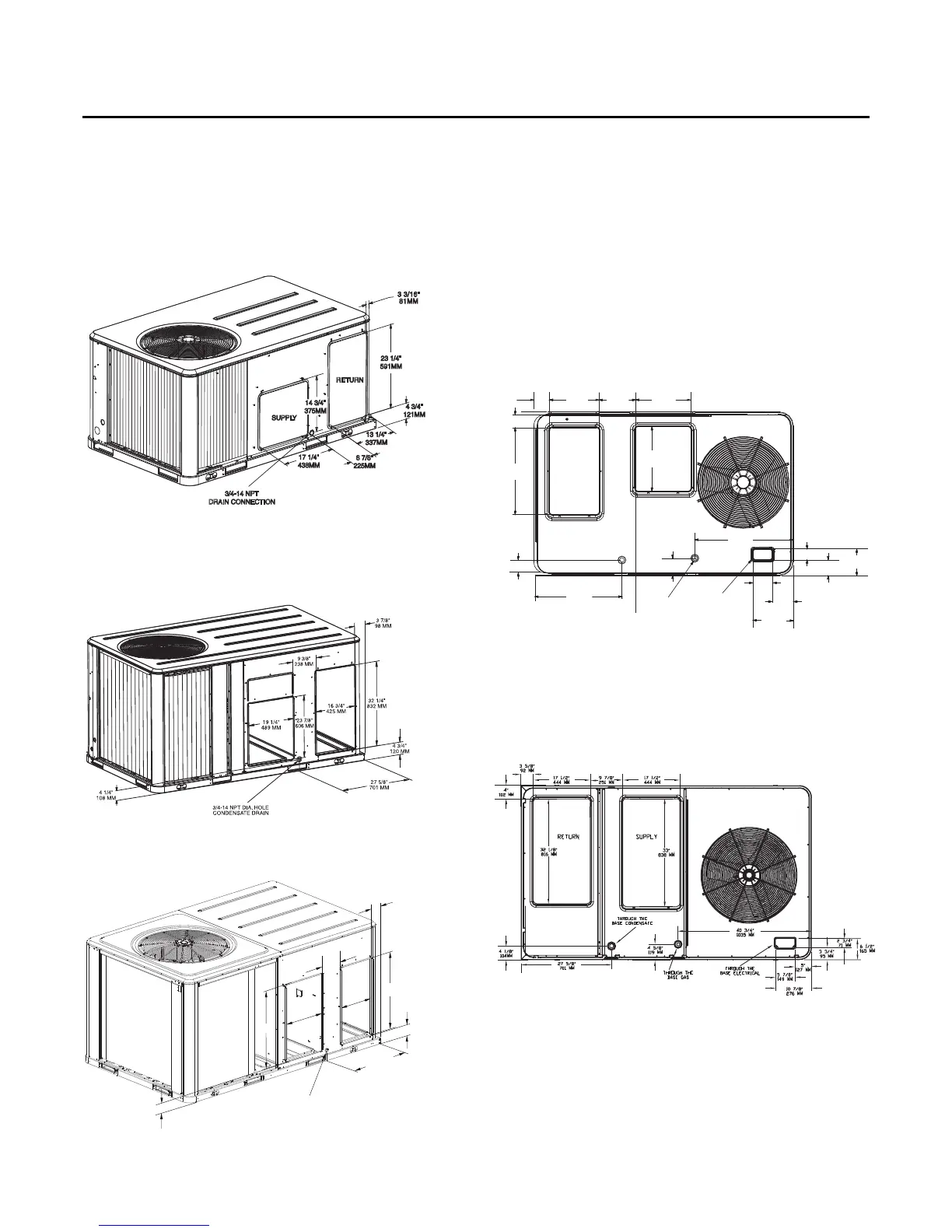

Figure 16, p. 25 to Figure 18, p. 25 illustrate the supply and

return air openings as viewed from the rear of the unit.

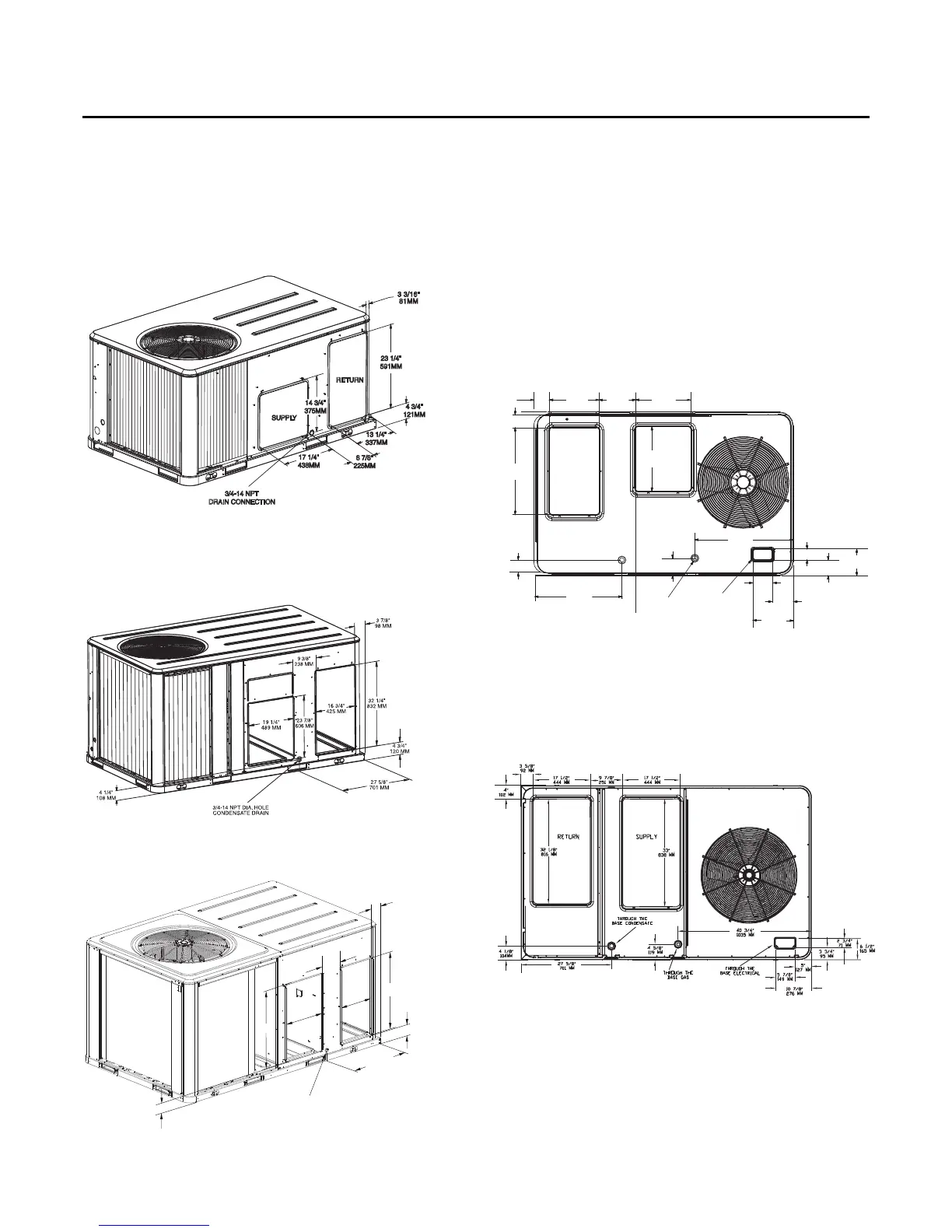

Figure 19, p. 25 to Figure 21, p. 26 illustrate the supply and

return air openings in a downflow configuration.

Elbows with turning vanes or splitters are recommended

to minimize air noise due to turbulence and to reduce static

pressure.

When attaching the ductwork to the unit, provide a water

tight flexible connector at the unit to prevent operating

sounds from transmitting through the ductwork.

All outdoor ductwork between the unit and the structure

should be weather proofed after installation is completed.

Figure 16. 3-5 ton standard efficiency units & 3 ton high

efficiency units - Horizontal supply & return

air openings

Figure 17. 4-6 ton high efficiency units, 7½-8½

(Microchannel) high efficiency unit and 6-10

ton standard efficiency units - horizontal

supply & return air openings

Figure 18. 10 ton high efficiency unit - horizontal supply

& return air openings

Supply

Return

3 7/8”

98 MM

9 3/8”

238 MM

19 1/4”

489 MM

16 3/4”

425 MM

4 3/4”

120 MM

32 1/4”

832 MM

27 5/8”

701 MM

Supply

Return

4 1/4”

108 MM

3/4-14 NPT DIA. HOLE

CONDENSATE DRAIN

32 1/4”

832 MM

Figure 19. 3-5 ton standard efficiency units&3tonhigh

efficiency units - Down flow supply & return air

openings w/ through-the-base utilities

Figure 20. 4-6 ton high efficiency units, 7½-8½

(Microchannel) high efficiency units and 6-10

ton standard efficiency units - down flow

supply & return air openings w/ through-the-

base utilities

THROUGH

THE BASE GAS

THROUGH

THE BASE

ELECTRICAL

SUPPLY

RETURN

TBU CONDENSATE

3 5/8”

92 MM

14”

356 MM

9 1/4”

235 MM

15 1/2”

394 MM

4”

102 MM

24”

610 MM

16”

406 MM

27 9/16”

701 MM

4 3/16”

106 MM

4 9/16”

116 MM

23 1/2”

597 MM

2 13/16”

71 MM

6 1/2”

165 MM

3 11/16”

94 MM

4 7/8”

124 MM

5 1/16”

128 MM

9 15/16”

253 MM

Loading...

Loading...