18

NOTE: The elements on UK models are to

240V specification and will give a lower kW

rating if the voltage supply is below 240V.

7

Continued

SECTIONSECTION

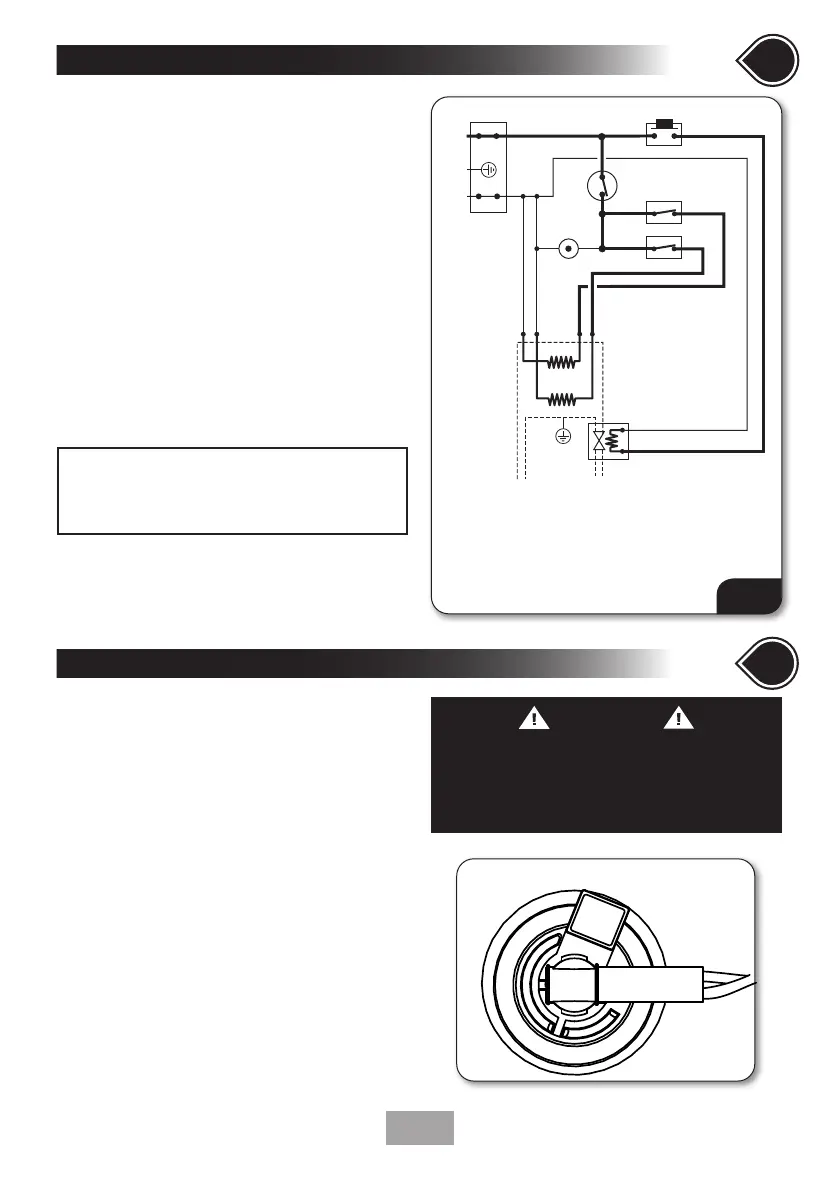

• Fig.12 shows a schematic wiring diagram.

IMPORTANT: When connecting the cable fully

tighten the terminal block screws and make sure

that no cable insulation is trapped under the

screws. Loose connections can result in cable

overheating.

NOTE: The supply cable earth conductor must

be sleeved. The outer sheath of the supply cable

must be stripped back to the minimum.

• The use of connections within the unit or

other points in the shower circuit to supply

power to other equipment i.e. extractor fans,

pumps, etc. will invalidate the guarantee.

• DO NOT switch on the electricity supply

until the shower cover has been fitted.

FITTING THE COVER

Figs 13, 14, 15 and 16 on page 19 show the

correct control knob position when replacing the

cover.

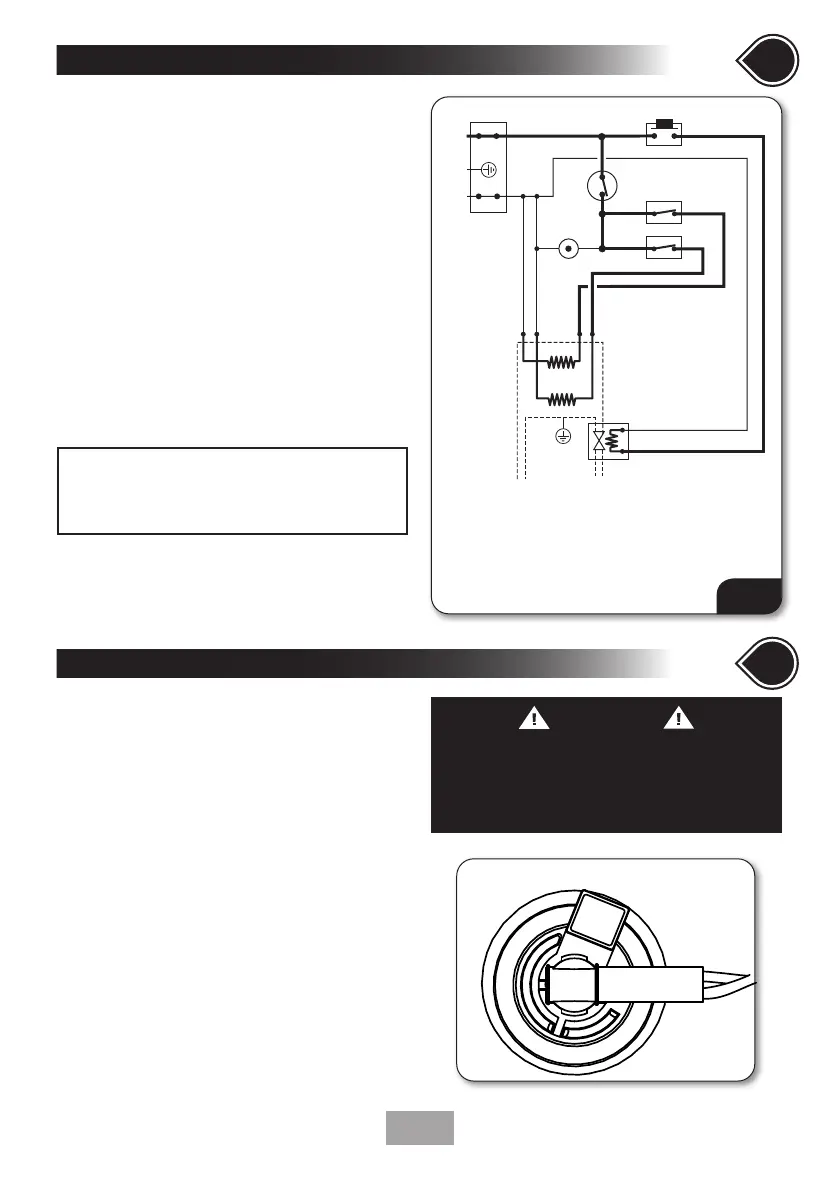

• Clip the neon into the back of the Start/Stop

assembly on the inside of the cover in the

correct orientation (shown below, right.)

• Check to ensure that the wiring is not

trapped and replace the cover squarely to

the backplate and guide into position so that

the knobs locate correctly into the splined

spindles.

• Should any difficulty arise, recheck the

points above.

• While applying slight pressure to the cover,

secure in position with the retaining screws.

• Fit the Riser Rail and Kit (see kit

instructions).

Installation - FITTING THE COVER

8

check list

SECTION SECTION

1.

2.

3.

4.

5.

6.

7.

Terminal block

Start/Stop switch

Power selector

Microswitch

Solenoid valve

Thermal cut-out (main)

Neon - power

Element

3

4

5

7

L

N

E

inlet

outlet

1

3

7

6

Fig.12

WARNING

COVER RETAINING SCREWS

ONLY the SUPPLIED SCREWS should be

used. The use of non supplied screws WILL

invalidate product specications & warranty.

CORRECT NEON FITTING ORIENTATION

Loading...

Loading...