36

Where the copper tube is protected by an insulation grip, the leak can be detected from both ends of each individual grip.

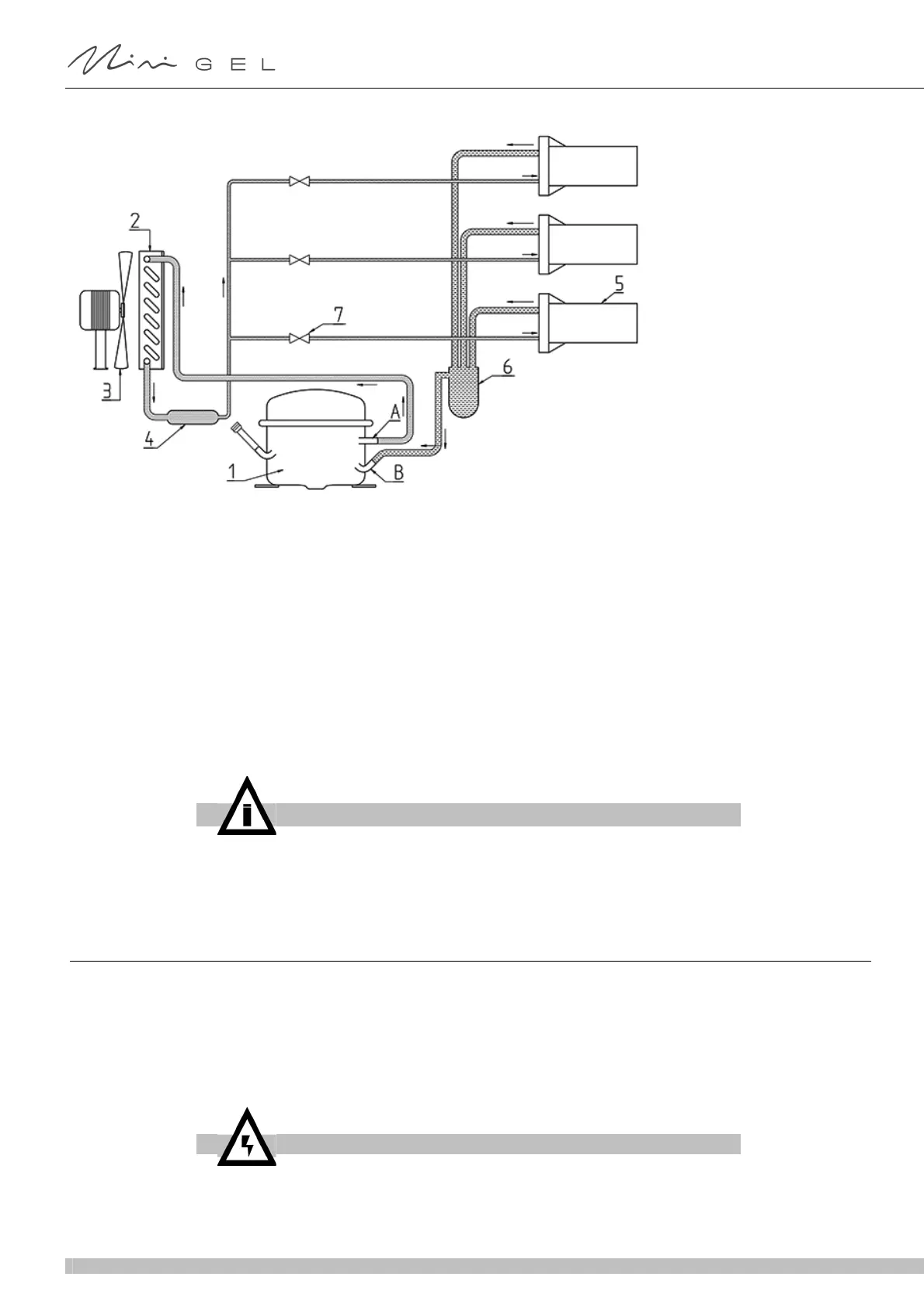

figure 3

Referring to figure 3, proceed as follows:

1 Begin the inspection at the “High Pressure” zone (discharge) of the compressor. Check around the seals.

2 Follow the copper pipes to the condenser and check the sealed connections at the condenser entrance and exit.

3 Also check the curves of the pipes on both sides of the condenser.

4 Follow the copper pipes to the evaporator, checking around the sealed connections on the dehydrator filter and the

electrovalves.

5 Disassemble the geared motors and check the evaporator capillary tube entry and the suction line outlet.

6 Check the copper pipes up to the compressor.

7 Inspect the “Low Pressure” zone of the compressor, checking the connections on the suction and inlet pipes.

8 Once the leak has been identified, seal it and charge with gas according to the instructions below.

12. 2 HOW TO EMPTY THE CIRCUIT

1 Remove all the machine’s panels.

2 Remove the cap from the “Charge” pipe valve on the compressor.

3 Connect the compressor “Charge” tube to the “Low” filling unit on the “pressure Gauge” (see figure).

4 Connect the "VAC” filling unit on the pressure gauge to an appropriate and approved gas collection device.

5 Open the “Low” and “VAC” valves and collect the gas.

A High pressure (discharge)

B Low pressure (suction)

1 Compressor

2 Condenser

3 Fan

4 Filter

5 Evaporator

6 Accumulator

7 Solenoid valve

IMPORTANT

Incorrect adjustment of the Production Parameters may compromise the opera-

tion of the machine.

WARNING

The refrigerant gas may be highly acidic and toxic.

Loading...

Loading...