10

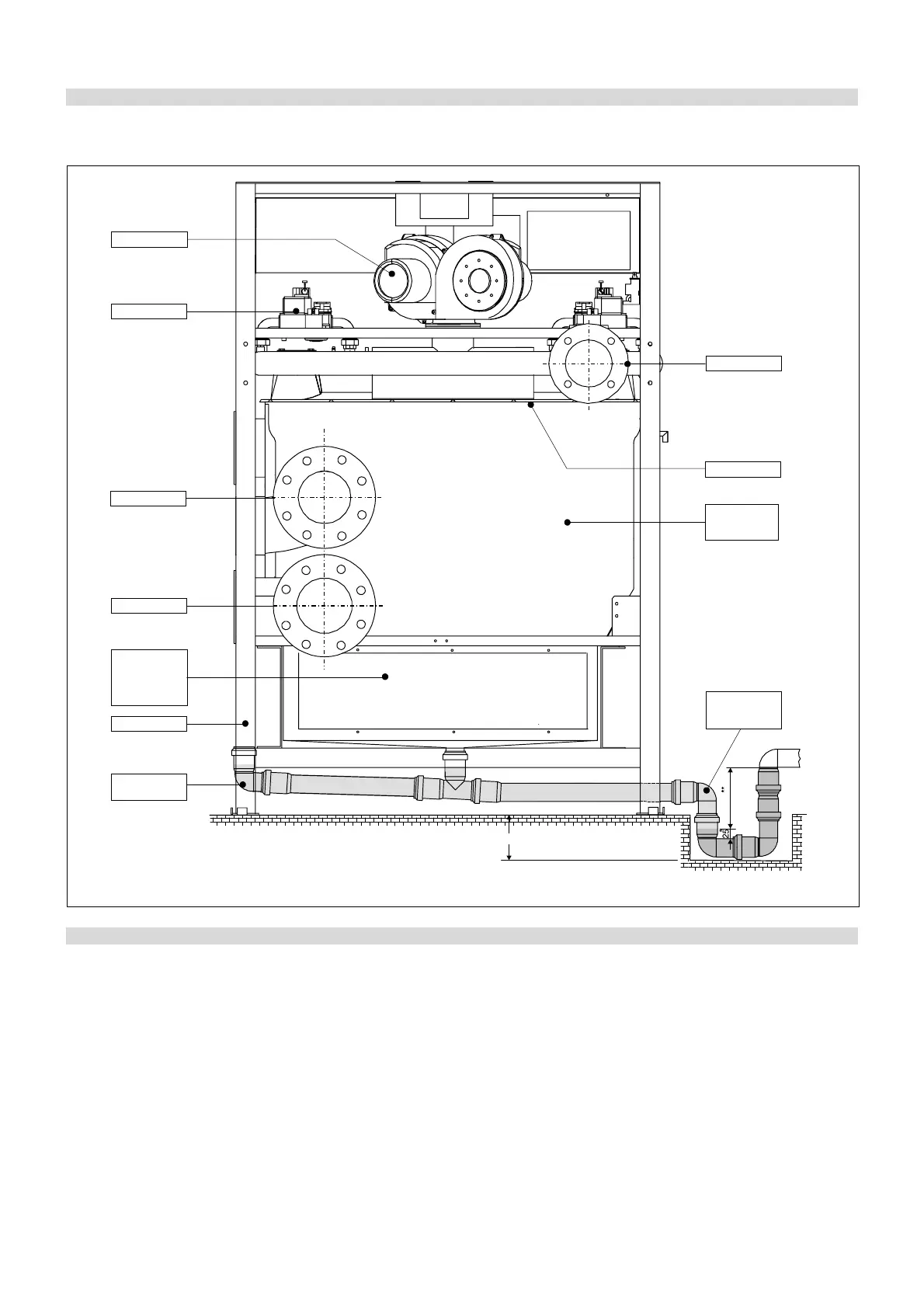

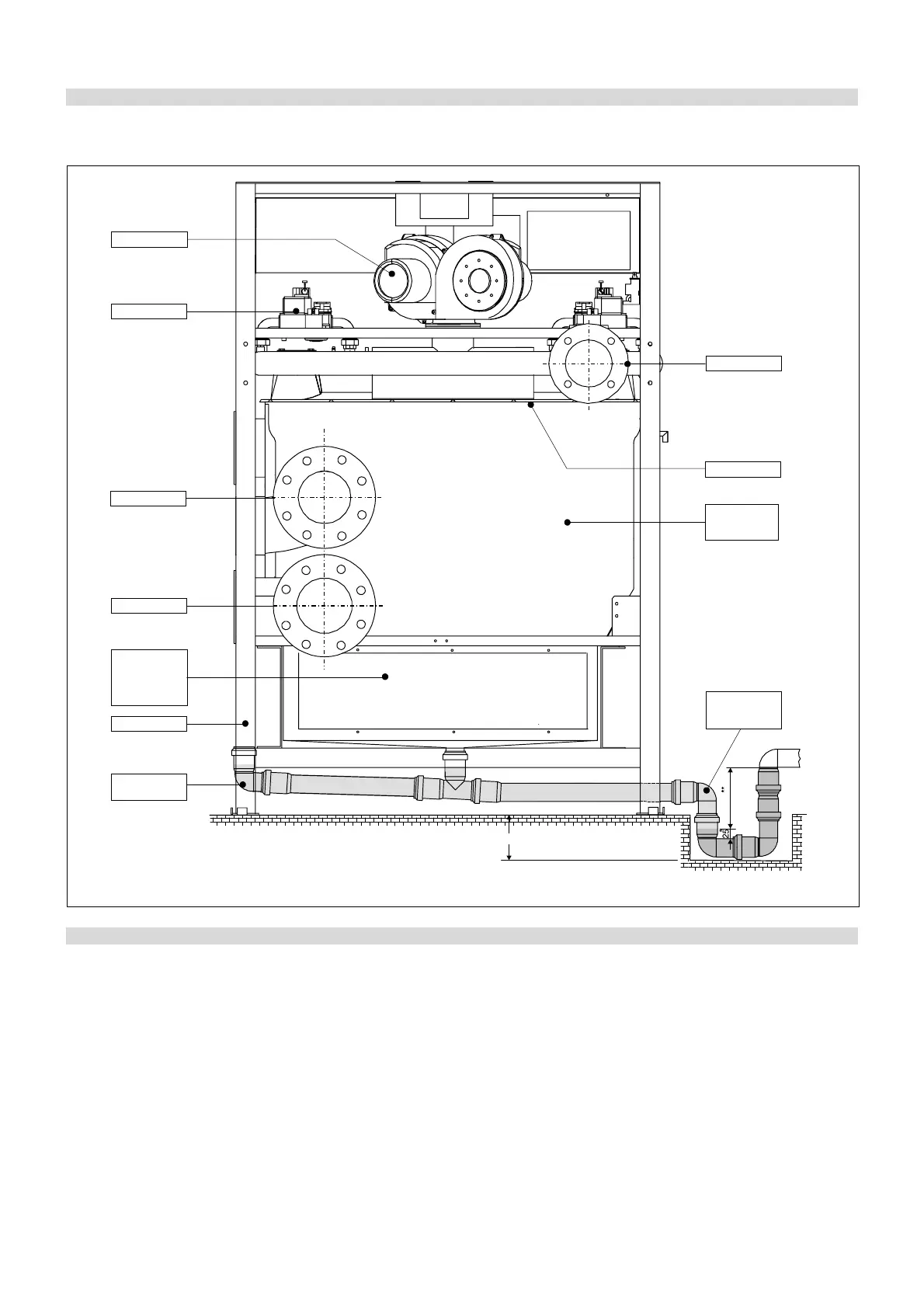

fig. 2

1.4 - SIDE VIEW WITH MAIN COMPONENTS

2.1 - COMPOSITION OF THE

SUPPLY

- Boiler body made of sections of alumi-

nium/magnesium/silicium alloy (5 to 8)

- Premix stainless-steel burner (4 to 7)

- Premixing chamber (8 to 14) with bu-

ilt-in non return valve

- Modulating fan (4 to 7) with air pres-

sure switch control

- Gas valve (2 for each module – from 8

to 14) with separated flame control

device SATRONIC (from 4 to 7)

- NTC sensors for local temperature con-

trol on each boiler section (5 to 8)

- NTC sensor for global flow manifold

temperature

- NTC sensor for global return mani-

fold temperature

- High Limit thermostat on each boiler

section (5 to 8)

- Automatic air vent on the flow mani-

fold

- Boiler draining/filling tap on return

manifold

- Minimum gas pressure switch on gas

manifold

- Condensate collecting tray

- Plastic pipe (1m) and fittings for con-

densate evacuation Ø40

- Smoke chamber terminal, with flue soc-

ket:

Ø 250 mm for models 360 and 450

Ø 300 mm for models 540 and 630

- Integral painted steel casing

- Modulation and control PCB (MBD)

with PC interface

- AM-4 PCB for DHW production and

outdoor temperature sensor

- Supplementary PCB type AM-5 (1 x

mod. 360; 2 x mod. 450 and mod. 540;

3 x mod. 630)

- Electronic card for interface

- Outdoor sensor (into the smoke cham-

ber)

150

FAN

GAS VALVE

GAS PIPE

BURNER

ALUMINIUM/

SILICON HEAT

EXCHANGER

CONDENSATE

DRAIN

SIPHON

CONDENSATE

COLLECTING

TRAY-

SMOKE

MANIFOLD

FILLING-UP

ELBOW

C.H. RETURN

C.H. FLOW

Min. Depth 100 mm

BOILER FRAME

Loading...

Loading...