13

2.2.4.1 - MATERIALS FOR FLUE

PIPES

As material can be used the stainless

steel AISI 316 L or AISI 316 Ti, with a

minimum wall thickness of 0.4 mm, or the

aluminium, with a minimum wall thickness

of 1.5 mm, or the PVDF (Polyvinildi-

methylfluorure), or the PPS (Simple trans-

parent polypropylene), certified for this

use. Other materials and thicknesses are

also admitted, provided they guarantee at

least equivalent caracteristics.

In case of tubing of an existing chimney

the flue pipe has to be of aluminium (min.

thickeness of 1.5 mm) or of stainless

steel (min. thickness of 0,4 mm) and its

connections have to be water proof.

2.2.2 - BOILER LOCATION INSIDE A

BOILER HOUSE

Special attention shall be paid to local reg-

ulations and laws about boiler houses and

particularly to the obligation of keeping

minimum clearances and empty space

around the boiler. The installation shall be

in compliance with all latest regulations

and laws about boiler houses, installations

of heating and hot-water systems, venti-

lation, chimneys capable of evacuating

the flue gases of condensing boilers and

any other applicable requirement.

When selecting the position for the

installation of the boiler it has to be

considered that, for the cleaning and

washing operations of the boiler

body, one of the boiler sides must be

accessible for the removal of a spe-

cial baffle placed under the aluminum

sections.

The boiler can be put on a flat and suffi-

ciently strong base with the same di

mensions as the boiler ones and at le-

ast 100mm high (see fig. 5), in order to

assemble the condensate drain siphon.

An alternative to this base may be a

100 mm deep well next to the boiler as

siphon housing (see fig. 2). After instal-

lation the boiler shall be

perfectly horizontal and stable, to redu-

ce any possible vibrations or noises.

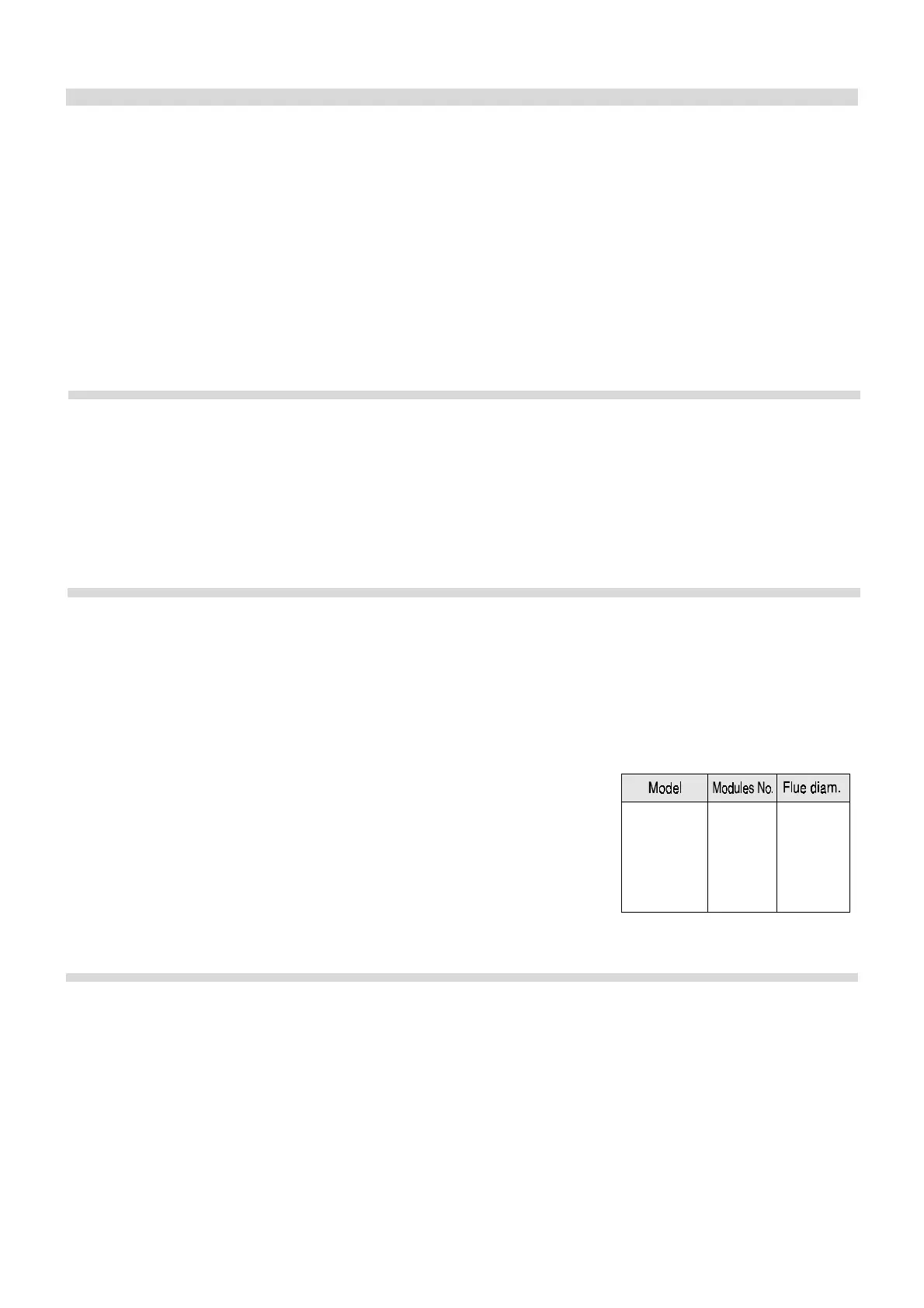

2.2.3 - BOILER CONNECTION

The boiler Modulex leaves the factory pre-

disposed for the hydraulic and gas con-

nection on the back side of the boiler. The

smoke outlet is placed on the back side

2.2.4 - CONNECTION TO THE

CHIMNEY

ATTENTION:

BEFORE ASSEMBLING THE CHIM-

NEY DUCT IT’S ABSOLUTELY NE-

CESSARY TO SET A SUPPORT UN-

DER THE SMOKE CHAMBER TERMI-

NAL

Into a condensing boiler, the smokes re-

ach a very low temperature (Max 84°C).

So, it’s necessary that the chimney is

perfectly impermeable to condensation of

combustion products and built with mate-

rials corrosion resistant.

The various spigot joints have to be well

sealed and endowed with provided for

gaskets, so that to prevent the conden-

sation spillage and the air entry.

For the chimney dimensioning, diameter

and height, it is necessary to make refe-

rence to the national and local regulations.

In order to avoid, during the operation, the

ice formation, the temperature of the insi-

de wall in every point of the system for

the combustion products evacuation, for

all of its length, doesn't have to be lower

than 0°C.

For operation in condensing conditions

with the outdoor temperature of project, it

will be therefore necessary the realiza-

tion of a system of confluent condensa-

tion drain, according to the installation

conditions, in the collection box of the

boiler or separated by it.

of the boiler for MODULEX 360; it's pla-

ced on the R.H. side of the boiler for MO-

DULEX 450 - 540 - 630.

For the smoke chamber fixing, use the

4

5

6

7

450

540

630

360

250

250

300

300

screws and gaskets included into the in-

struction bag, and a cross screwdriver at

least 300 mm of length.

Loading...

Loading...