20

2.4.1 - GENERAL DESCRIPTION

When there is an heat request from a

room thermostat or an outer compensa-

tor, the Modular Boiler Drive (MBD) cal-

culates the necessary output according

to the difference between the set tempe-

rature (or the temperature calculated by

the outer compensator) and the global

flow temperature. The number of thermal

elements (each thermal element repre-

sents a maximum output of 90 kW) x

100% determines the maximum output

expressed in %.

When the output has been determined, the

boiler pump (not supplied by Unical) is set

up and the fan of one thermal element is

set in motion at starting speed. The gas

valve opens and ignition is to occur with-

in 5 sec. When the ionisation electrode

detects the flame, the thermal element

starts operating.

Subsequently other thermal elements are

likely to start in the same way. One of the

operation principles for this boiler is let-

ting as many burners as possible oper-

ate simultaneously at minimum load to

reach the maximum efficiency.

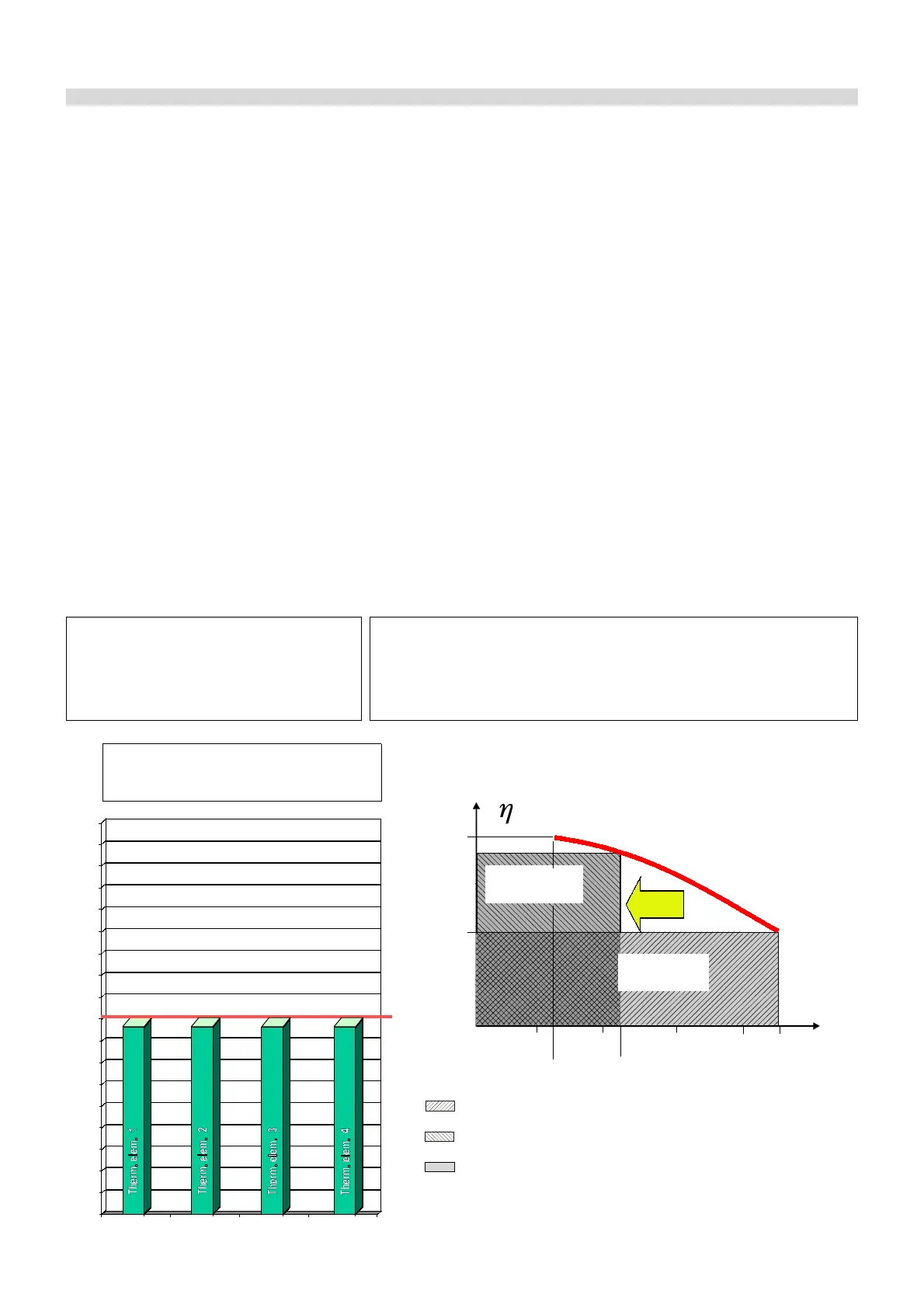

For example, if a 4 thermal element boiler

is requested to operate at its max output,

this shall be 400% i.e. :

90 kW x 4 thermal elements =

360 kW = 400%.

If it is requested to operate at 200% out-

put, thanks to the output sharing system

on the highest number of thermal ele-

ments, each thermal element will operate

at 50% output i.e. :

200% : 4 thermal elements = 50%

equal to a total of 180 kW, that is 45 kW

for each thermal element.

1 Thermal element = 90 kW = 100%

4 Thermal elem. = 90 kW x 4 = 360 kW = 400%

400% : 360kW = 200% : X

X = (200x360) : 400 = 180 kW

output shared on 4 thermal elements

Output shared on 4 thermal elements : total output

= 180:360 = 0,5 = 50%

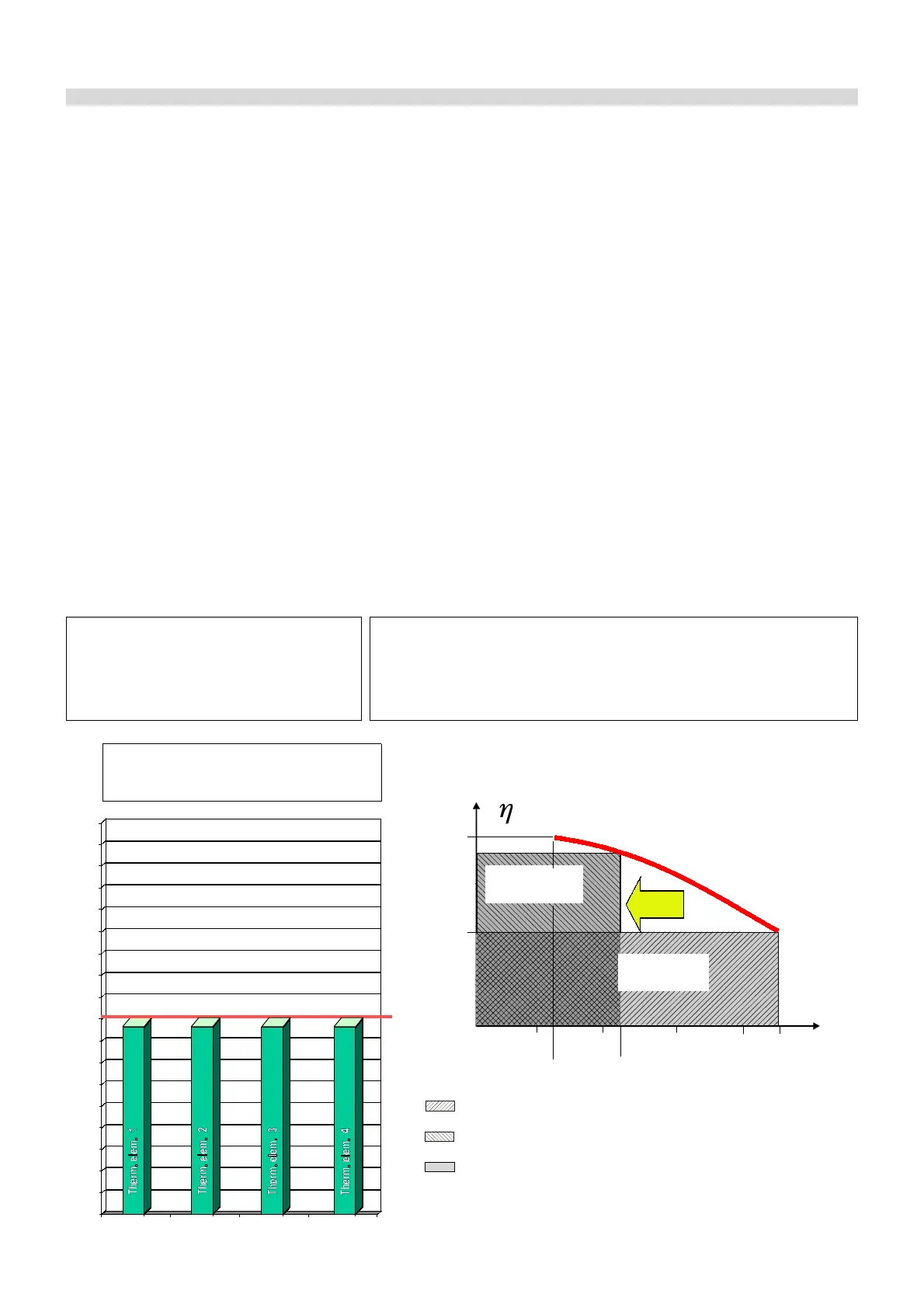

Such principle provides clearly efficien-

cies much higher than those obtained in

traditional groups of small boilers installed

in cascade.

When the output shared on each thermal

element is less than 22 kW, one thermal

element after the other is automatically

excluded and the remaining output is

shared on thermal elements having the

smallest number of operation hours (by

the automatic operation-time calculating

system).

Modulation, i.e. output reduction, is based

on the difference between the set temper-

ature (or the temperature calculated by

the outer compensator) and the global

flow temperature.

When no ignition occurs, the ignition de-

vice puts to lock out position the thermal

element concerned.

Efficiency of a thermal element working at full capacity

(90 kW) = 103 % (in condensation)

Efficiency of a thermal element working at reduced capacity

(45 kW) = 107 % (in condesation)

Efficiency of a thermal element working at minimum capacity

(22 kW) = 109 % (in condesation)

All the thermal elements work in parallel at the same output, equalizing,

thus, the C.H. system efficiency to the one of the thermal element.

0

5

10

15

20

25

30

35

40

kW

mod 1

45

50

55

60

65

70

75

80

85

90

4 thermal elements of 90 kW each working

at 50% of the output give = 180 kW = (200%),

i.e. 45 kW / thermal element

% (p.c.i.)

P

(kW)

20

105

109

40 8060

107

100 % = 90 kW

50 % = 45 kW

90

45

22

1 thermal

element

1 thermal

element

Loading...

Loading...