42

5

MAINTENANCE

1

st

phase –

Opening for modules inspection

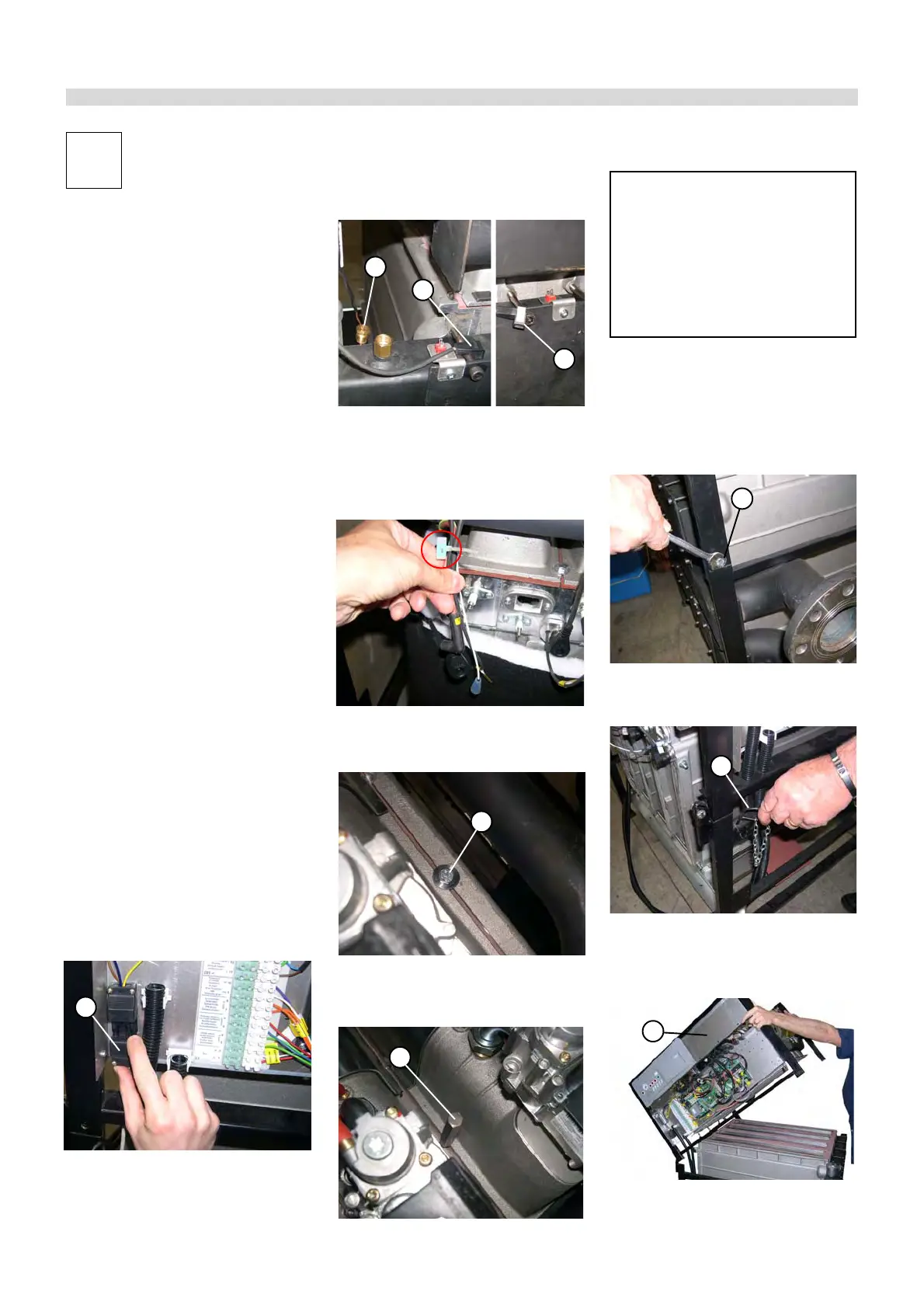

• Close the voltage and gas feeding

• Unloose the gas inlet connection and

separate the gas feeding pipe from the

boiler

• Remove all the jackets

• Remove the plug “A” for 230V supply

of the boiler

• Remove the cover in order to access

to the electric section

Only for Modulex 360, remove the

electric connection of flow sensor “B”

(black), return “C” (white) and the wa-

ter pressure gauge connection “D”

B

• Remove all the mixer outer fixing

screws “E” with 13 mm pipe tool.

A

D

C

E

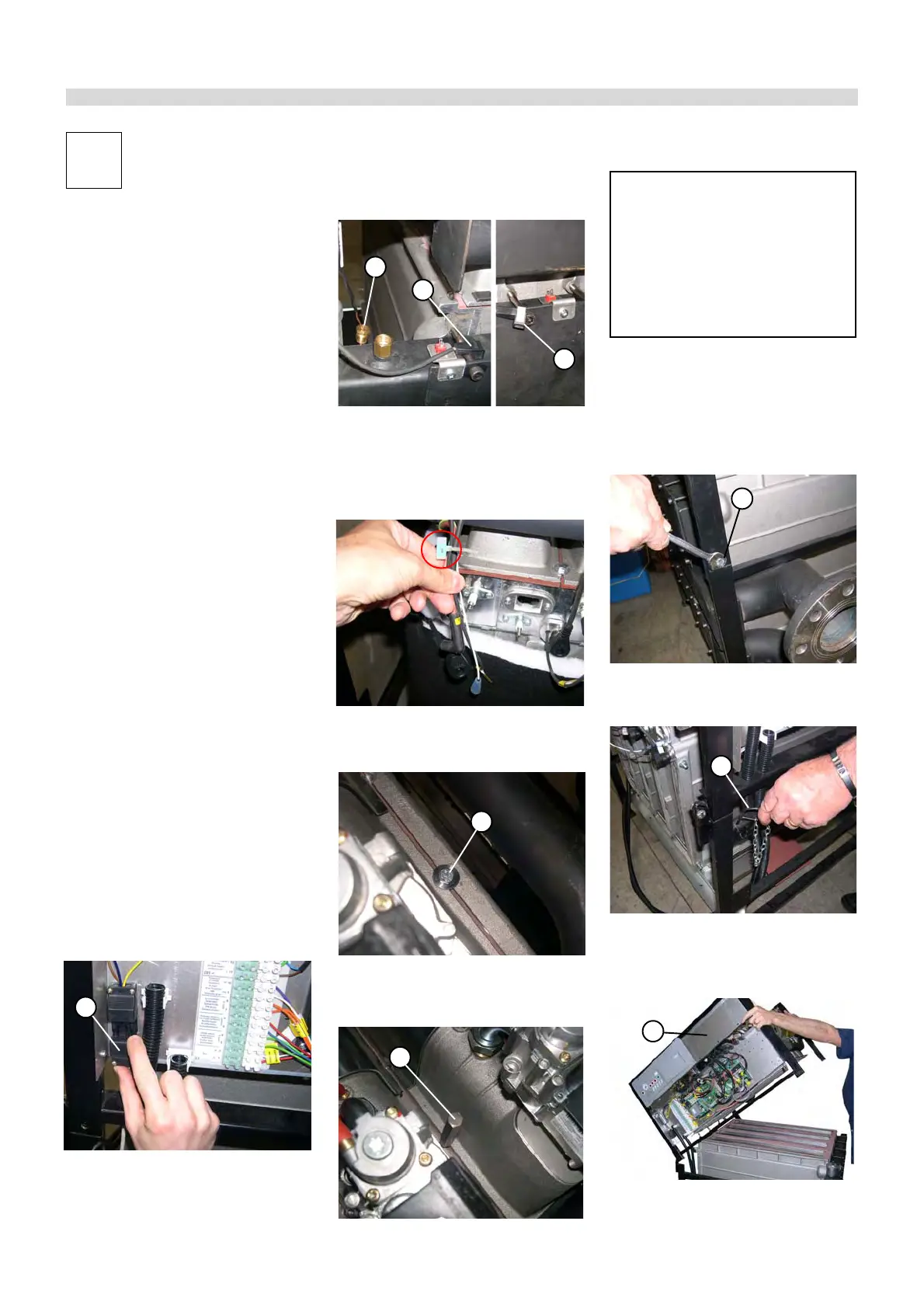

• Remove all the mixer inner fixing

screws “F” with 14 mm pipe tool.

• Remove the 2 screws “G” on the front

right and rear right frame supports

(both on the left for Modulex 450-540-

630) with 13 mm tool

F

• Remove the safety spring “H” of the

support bar “L” for upper opening.

• Lift up the upper boiler part “I”. For

Modulex 450-540-630 the opening will

be done on the opposite side.

G

H

I

The sequence here reported for the

modules inspection is for a MOD-

ULEX 360.

For boilers MODULEX 450, 540

and 630 these steps are a little

different, for example for the cable

removal and for the opening that will

be done on the opposite side (left

side).

• Only for Modulex 450-540-630, remo-

ve the electric connections of the mo-

dules, marked by the label 1…..6 or 7

(limit thermostat, ignition and detection

electrode, hearting and immersion sen-

sor)

5.1 - MAIN FEATURES

If the boiler is correctly adjusted, it about

doesn't need maintenance; it only needs

to be checked once a year and, if nec-

essary, be cleaned. In any case the fre-

quency of the cleaning depends on the

cleaness of the air sucked for the com-

bustion. As much as the dust present in

the air will be sucked inside the com-

bustion chamber, the smoke side resist-

ance will increase, which, finally, will

result in a reduced heat input (and con-

sequently a reduced output).

Before cleaning the boiler body sections,

check the boiler input and the CO

2

per-

centage (see 3.5). If the actual input (with

the correct CO

2

) is within 5% of the value

shown in the chapter 3, the boiler does

not need to be cleaned.

The operation then, can be limited to

the cleaning of the siphon.

Note! A reduction of the input can be

caused by the obstruction of the eva-

cuation duct or of the air intake. Check,

first of all, that this is not the reason.

Loading...

Loading...