43

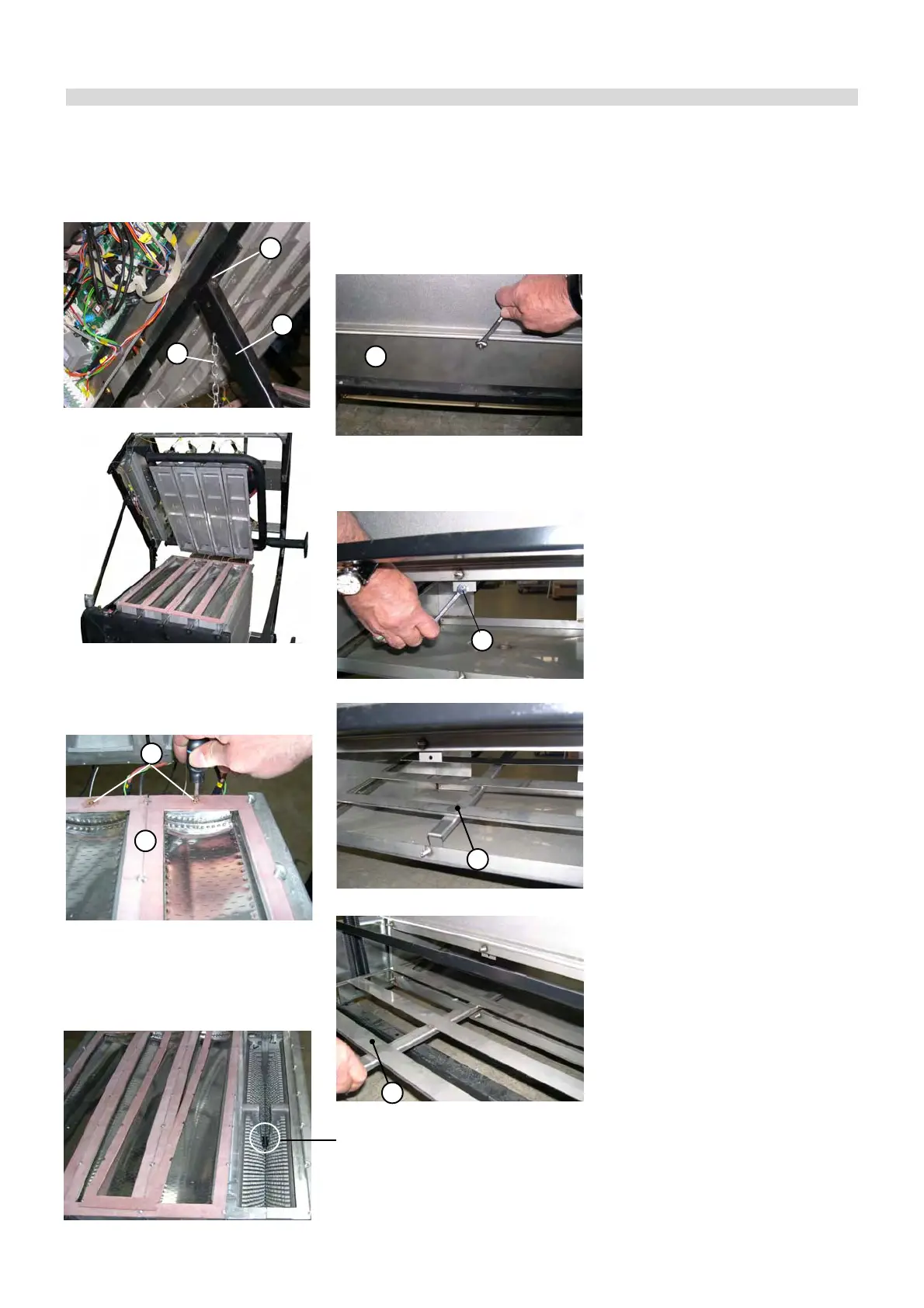

• Remove the burner gaskets “N”, remo-

ving the fixing screws “O”, and the bur-

ners.

The burner gaskets have to be repla-

ced every maintenance operation; they

have to be set between the burner and

the mixer, NOT BETWEEN THE BUR-

NER AND THE ALUMINIUM BODY!!

3

rd

phase – Cleaning

• Blow into the burners compressed air

from flame side (metallic spounge) to

the gas side (slick).

• Wash, with a water jet, the combustion

chamber: pay attention to not to wet

the electrical wiring. During this ope-

ration ascertain that the condensate

evacuation pipe is always free, so that

the water cannot come out from the

tray.

• Blow with compressed air in the com-

bustion chamber, in between the sec-

tions, so that all dirty parts are remo-

ved from the aluminum protrusions.

• Inspect the flue duct and the smoke

chamber.

N

O

4

th

phase – Reassembly

• Replace the burner sealing gaskets

• Proceed with the re-assembling fol-

lowing the same steps at the contrary.

Note: for the baffle “Q” setting into the

condensation collector, use the provi-

ded for sliding tracks.

• Before starting the boiler ascertain that

the condensate siphon is filled with

water.

• Before opening the gas feeding, che-

ck that the gas connection (previously

disconnected) is now correctly sealed.

To do this, open the gas cock and che-

ck the soundness of the coupling using

a soap solution.

• As soon as a burner is put into opera-

tion check immediately the soundness

between the gas valve and the rele-

vant premixing chamber.

• Make the combustion analysis and

check the combustion parameters..

• Make sure that all the gas pressure

test nipples, previously open, are clo-

sed and tight.

P

Q

R

R

L

M

H

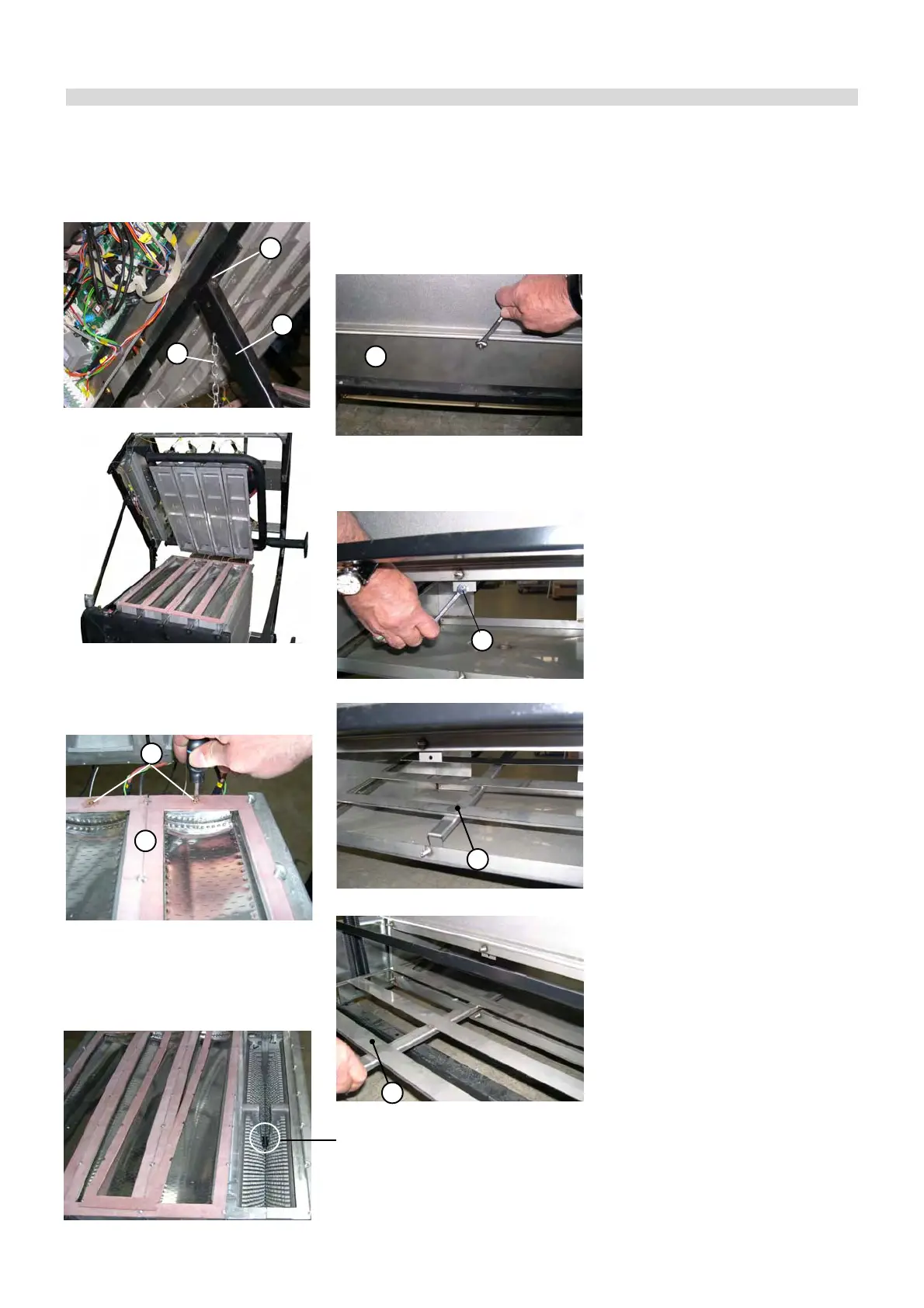

• Remove the Ø 7 fixing screw “Q” of

baffle “R”

2

nd

phase

baffle removal

• Access to the condensation collector

by removing the Ø 10 screws of the

inspection flange “P”, on the opposite

side of the chimney connection.

• Set the support bar “L” in the provi-

ded for position on frame support “M”,

locking it with the spring “H”

• The boiler is open

BAFFLE POSITION

If removed or moved

during the boiler clean-

ing, it has to be set again

into the original position.

Loading...

Loading...