TACHOMETER

TACHOMETER/HOUR

METER

The

tachometer/hour meter used in propulsion engine instru-

ment panels contains two separate electrical circuits with a

common ground. One circuit operates the hour meter and the

other the tachometer. The hour meter circuit operates on

12

volts

alternator charging voltage supplied to the (

+)

terminal

on

the back

of

the instrument.

The

tachometer circuit operates on

AC

voltage 6-8 volts, fed

from

one

of

the diodes in the alternator and supplied

m.

the

tachometer input terminal while the engine is running, and

the

alternator producing battery charging voltage 13.0-14.8

volts

DC.

The

following are procedures to follow when troubleshooting

· a fault

in

either

of

the two circuits in a tachometer/hour

meter.

Hour

meter

Inoperative

Check for the proper DC voltage between ( +) and (-)

terminals.

1.

Voltage present- meter is defective- repair or replace.

2.

Voltage not present - trace ( +) and (-) electrical con-

nections for fault. (Jump 12 volts

DC

to meter(+)

terminal to verify the operation.)

.

Tachometer

Inoperative

Check for the proper AC voltage between tachometer input

terminal and

(-)

terminal with the engine running.

1.

Voltage present - attempt adjusting meter through calibra-

tion access hole. No results, repair or replace meter.

2.

AC

voltage not present - check for proper alternator DC

output voltage.

3.

Check for AC voltage at tach terminal on alternator

to

ground.

4.

Check electrical connections from tachometer input ter-

minal

to

alternator connection.

Tachometer

Sticking

1.

Check for proper AC voltage between "tach inp." termi-

nal

and (-) terminal.

2.

Check for good ground connection between meter(-) ter-

minal and alternator.

3.

Check that alternator is well grounded to engine block at

alternator pivot bolt.

Tachometer

Inaccurate

1.

With a hand-held tach on the front

of

the crankshaft

pulley retaining nut or using a strobe type tach, read the

front crankshaft pulley rpm at idle.

2.

Adjust the tachometer using an 2mm Allen head wrench

5/64 (2mm) through the calibration access hole in the rear

of

the tachometer. Zero the tach and bring it to the rpm

indicated by the strobe or hand tach (verify rpm at idle

and at high speed). Adjust the tach as needed.

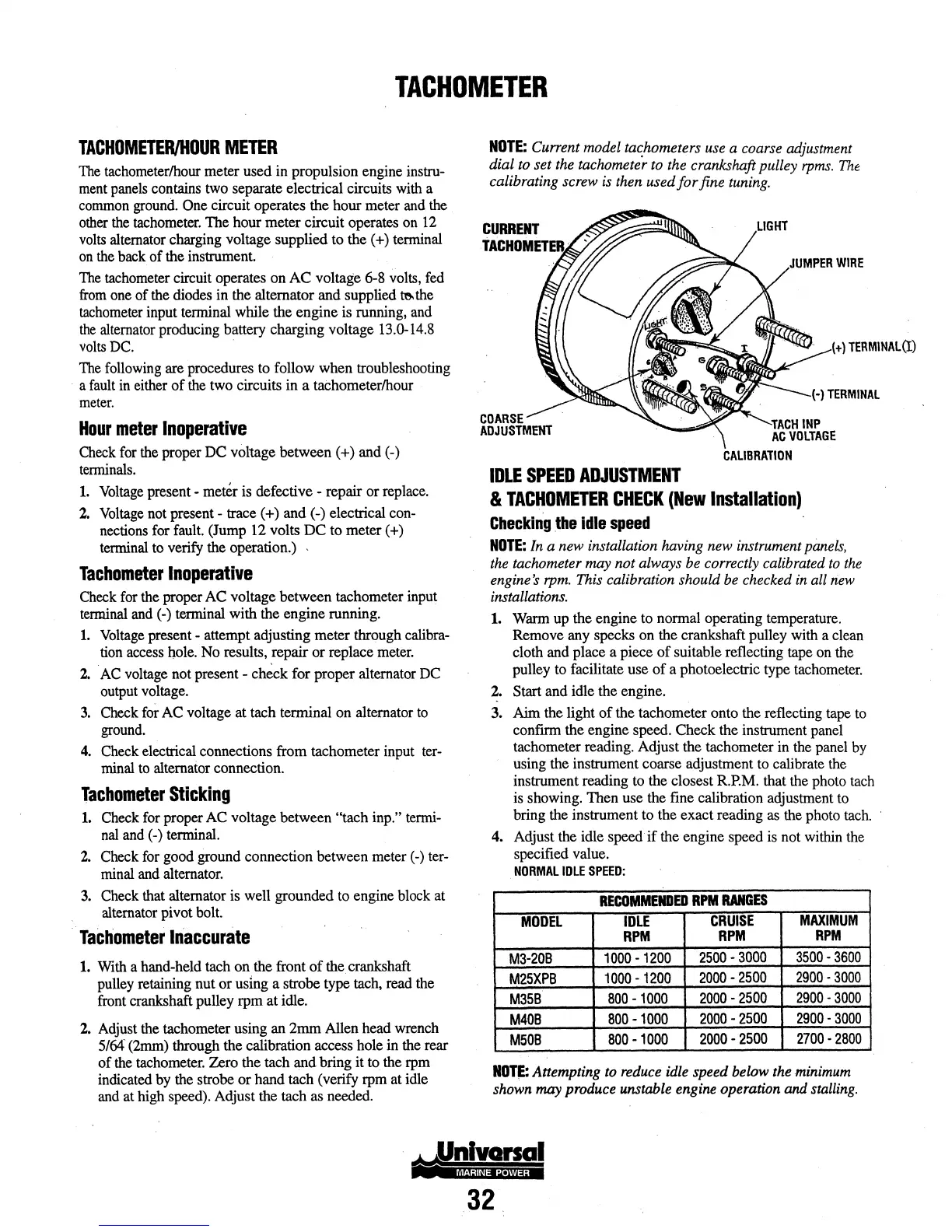

NOTE:

Current model tac_hometers use a coarse adjustment

dial to set the tachometer to the crankshaft pulley

rpms.

The

calibrating screw

is

then used

for

fine tuning.

(+)

TERMINAL(l)

CALIBRATION

IDLE

SPEED

ADJUSTMENT

&

TACHOMETER

CHECK

(New

Installation)

Checking

the

idle

speed

NOTE:

In a new installation having new instrument panels,

the tachometer may

not

always be correctly calibrated

to

the

engine

:S

rpm. This calibration should be checked

in

all new

installations.

1.

Warm up the engine to normal operating temperature.

Remove any specks on the crankshaft pulley with a clean

cloth and place a piece

of

suitable reflecting tape on the

pulley to facilitate use

of

a photoelectric type tachometer.

2. Start and idle the engine.

3.

Aim the light

of

the tachometer onto the reflecting tape to

confirm the engine speed. Check the instrument panel

tachometer reading. Adjust the tachometer in the panel

by

using the instrument coarse adjustment to calibrate the

instrument reading to the closest

R.P.M. that the photo tach

is showing. Then use the

fine calibration adjustment to

bring the instrument to the exact reading as the photo tach.

4. Adjust the idle speed

if

the engine speed is not within the

specified value.

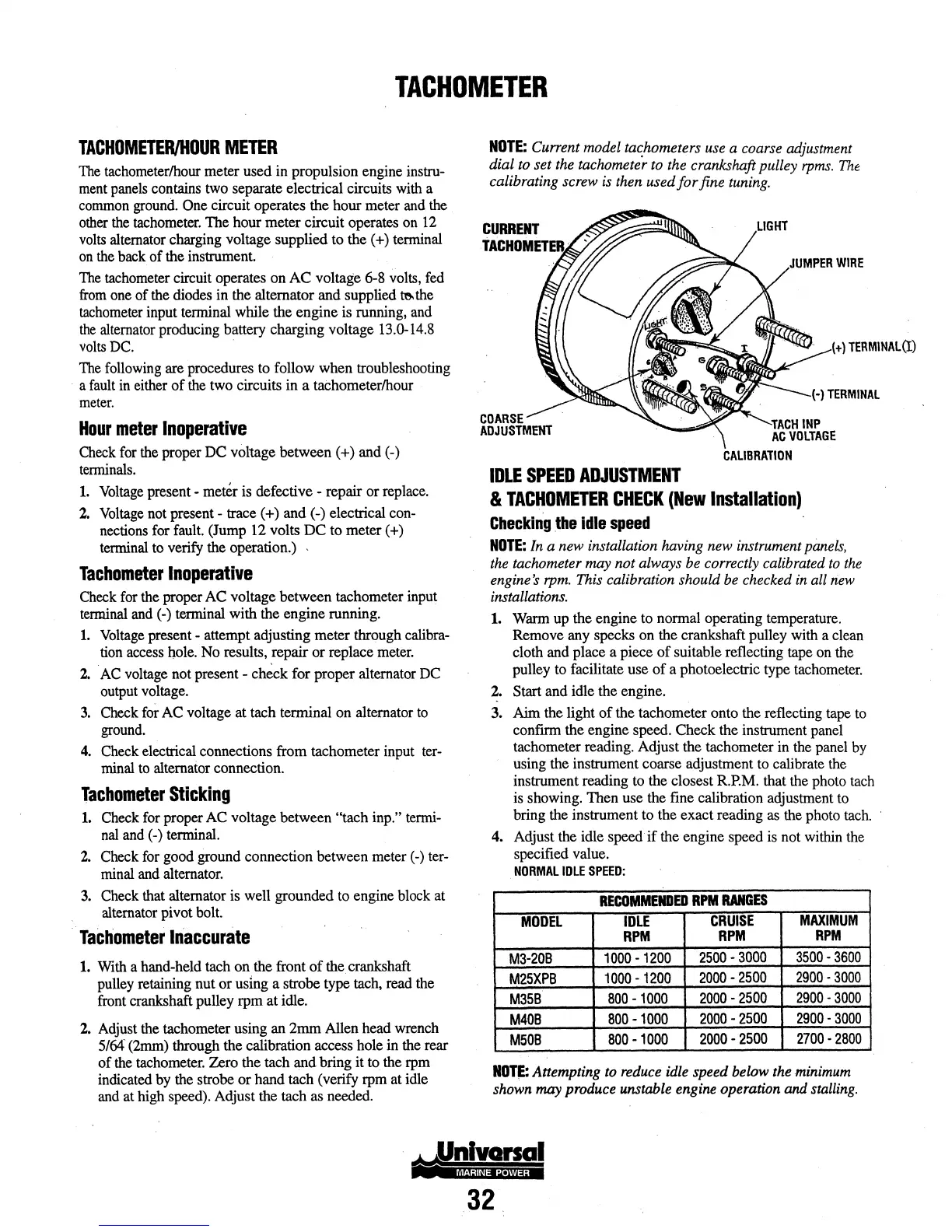

NORMAL

IDLE

SPEED:

RECOMMENDED

RPM

RANGES

MODEL

IDLE

CRUISE

MAXIMUM

RPM

RPM

RPM

M3·20B

1000

-1200

2500-3000

3500-3600

M25XPB

1000-1200

2000-2500

2900-3000

M35B

800-1000

2000-2500

2900-3000

M40B

800-1000

2000-2500

2900-3000

MSOB

800-1000

2000-2500

2700-2800

NOTE:

Attempting to reduce idle speed below the minimum

shown

may

produce unstable engine operation and stalling.

4

,.~,Univarsal

a a

m·,;l@tu·wia;•

32

Loading...

Loading...