Page 16 Operator Manual

067903-004R1 LX Series Work Platform Maintenance

E

NGINE

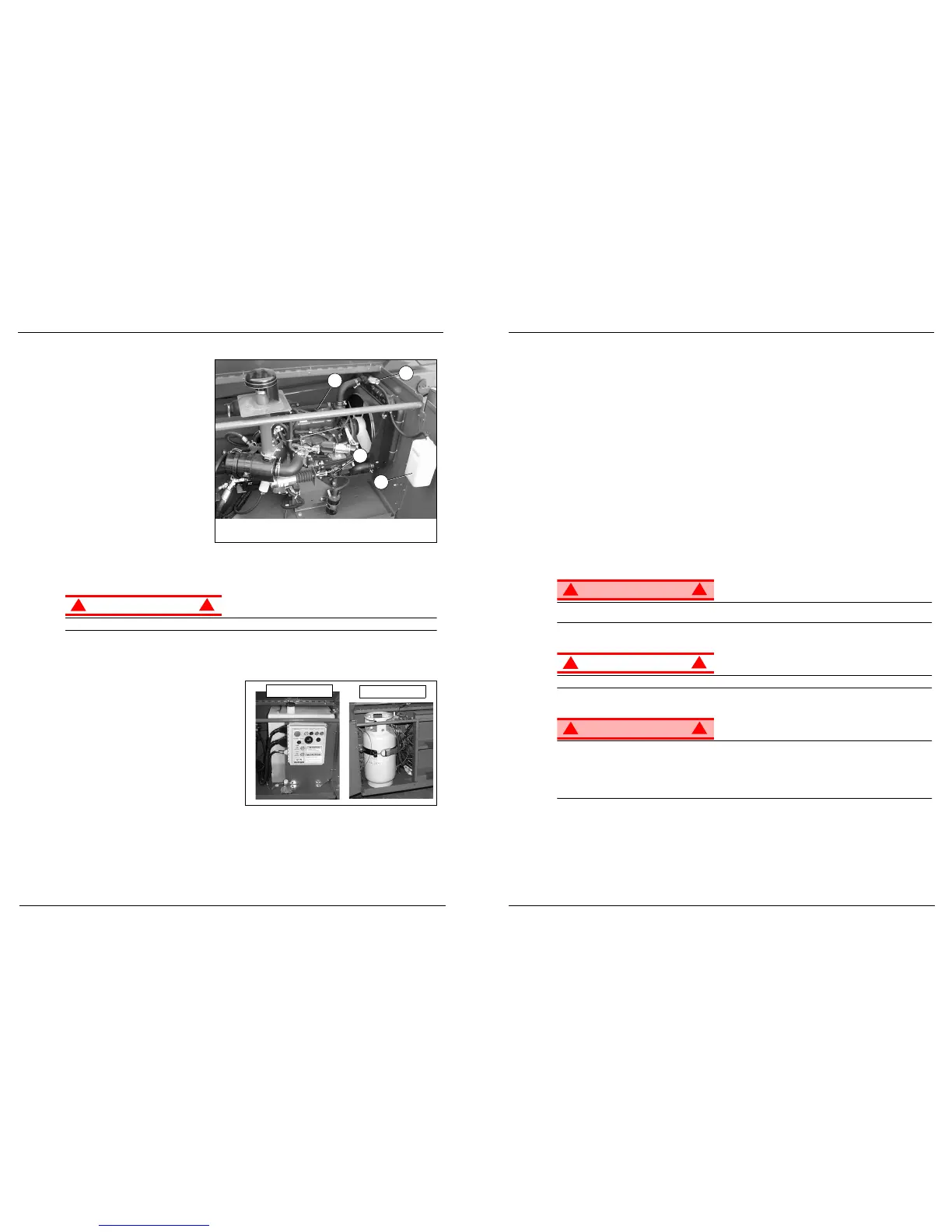

Figure 14:

Engine

C

OOLANT

The coolant recovery tank is mounted

on the inside of the door of the power

module.

1. Remove the cap on the coolant

recovery tank.

2. Add coolant to the “FULL” mark.

NOTE:

Never remove the radiator cap when

the engine is hot.

O

IL

The engine

must not be running

when you check and replenish the

engine oil. Refer to the Service Manual

to change the oil filter.

1. Remove the oil dipstick and check

the level indicator marks.

2. If the level is low, remove the oil filler cap.

3. Replenish with the proper engine oil (refer to the engine service manual that came with the machine).

CAUTION

!

!

DO NOT check coolant when engine or radiator is hot; hot coolant can cause severe burns.

F

UEL

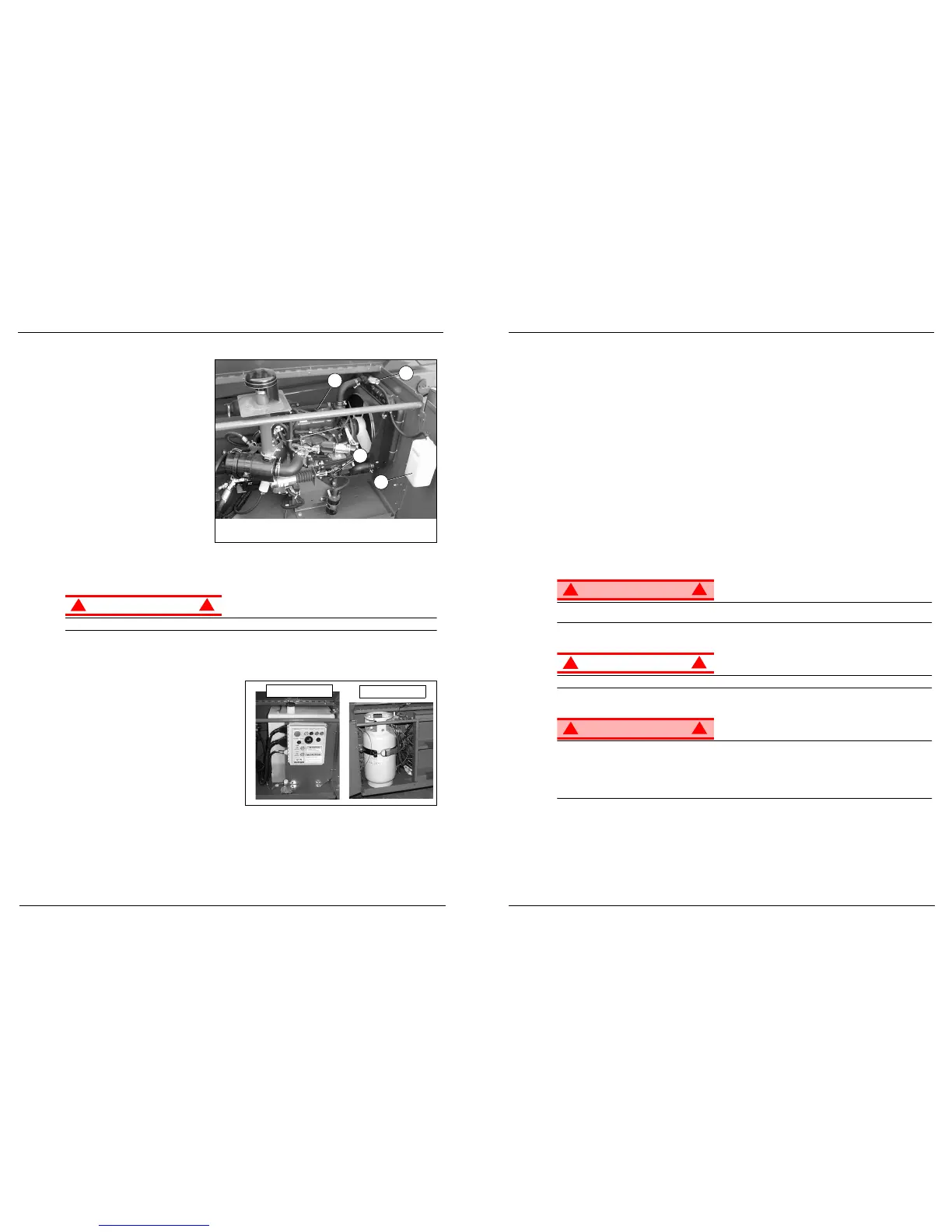

Figure 15:

Fuel Supply

D

IESEL

OR

G

ASOLINE

IMPORTANT: Fill with the correct fuel! Observe the

label near the fuel tank. It will say “Gasoline Only”

or “Diesel Only”.

The fuel tank for gasoline or diesel machines is

located in the Control Module, behind the chas-

sis controls. The tank is translucent. Check the

fuel level by observing the level of the liquid

through the tank.

P

ROPANE

(LP G

AS

)

The propane tank (dual fuel machines) is located in the Control Module to the left of the ladder, in front of

the battery.

3

4

1

2

1 Radiator Cap

2. Coolant Recovery Tank

3. Oil Filler Cap

4. Oil Dipstick

Propane (LP Gas)

Diesel or Gasoline

Pre-Operation & Safety Inspection 067903-004R1 LX Series Work Platform

Operator Manual Page 5

P

RE

-O

PERATION

& S

AFETY

I

NSPECTION

NOTE:

Carefully read, understand and follow all safety rules, operating instructions, labels and the Scaffold Industry

Association’s MANUAL OF RESPONSIBILITIES. Perform the following steps each day before use.

1. Open modules and inspect for damage, oil leaks or missing parts.

2. Check the hydraulic oil level sight gauge on the hydraulic tank with the platform fully lowered. Add fluid if

necessary.

3. Check that fluid level in the battery is correct (see “Battery Maintenance” on page 15).

4. Check the engine oil level and fuel level.

5. Check that all guardrails are in place, the slide-out deck extension is secured with the pin, and all fasten-

ers are properly tightened.

6. Check tire pressure: LX31 and LX41 - 3,4 bar (

50 psi

). The LX50 is equipped with poly-filled tires.

7. Carefully inspect the entire work platform for damage such as cracked welds in structural members,

loose or missing parts, oil leaks, damaged cables or hoses, loose connections and tire damage.

8. Carefully inspect the limit switches for signs of tampering.

9. Dual Fuel Models: set the dual fuel selector to the desired position. Set to the center position to purge

the system when switching fuels. If the machine is to be operated on propane, open the supply valve on

the tank

NOTE:

When using LP gas, use clean, water-free liquid petroleum gas, preferably from a bulk storage tank. Follow the

instructions located on the power module tray for filling the tank.

If you smell propane, close the supply valve on the tank immediately until you have located and

corrected the leak.

10. While the engine is cool, check the engine coolant level.

DO NOT check coolant when engine or radiator is hot; hot coolant can cause severe burns.

S

YSTEM

F

UNCTION

I

NSPECTION

STAND CLEAR

of the work platform while performing the following checks.

Before operating the work platform, survey the work area for surface hazards such as holes, drop-offs,

bumps and debris.

Check in

ALL

directions, including above the work platform, for obstructions and electrical conductors.

Protect control console cable from possible damage while performing checks.

1. Move the machine, if necessary, to an unobstructed area to allow for full elevation.

2. Place chassis and platform emergency stop switches in the ON position (Figure 3, Page 4) by pulling the

buttons out.

3. Verify that the platform/chassis switch is set to PLATFORM (Figure 3, Page 4).

4. Unhook the controller from the front guardrail. Firmly grasp the controller hanger in such a manner that

the interlock lever switch can be depressed, while performing the following checks from the ground.

5. Turn the controller key switch clockwise to ON. Turn fully clockwise to start the engine, releasing the key

once the engine starts.

Loading...

Loading...