page 15 of 27

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. 25/11/2013 // 999281

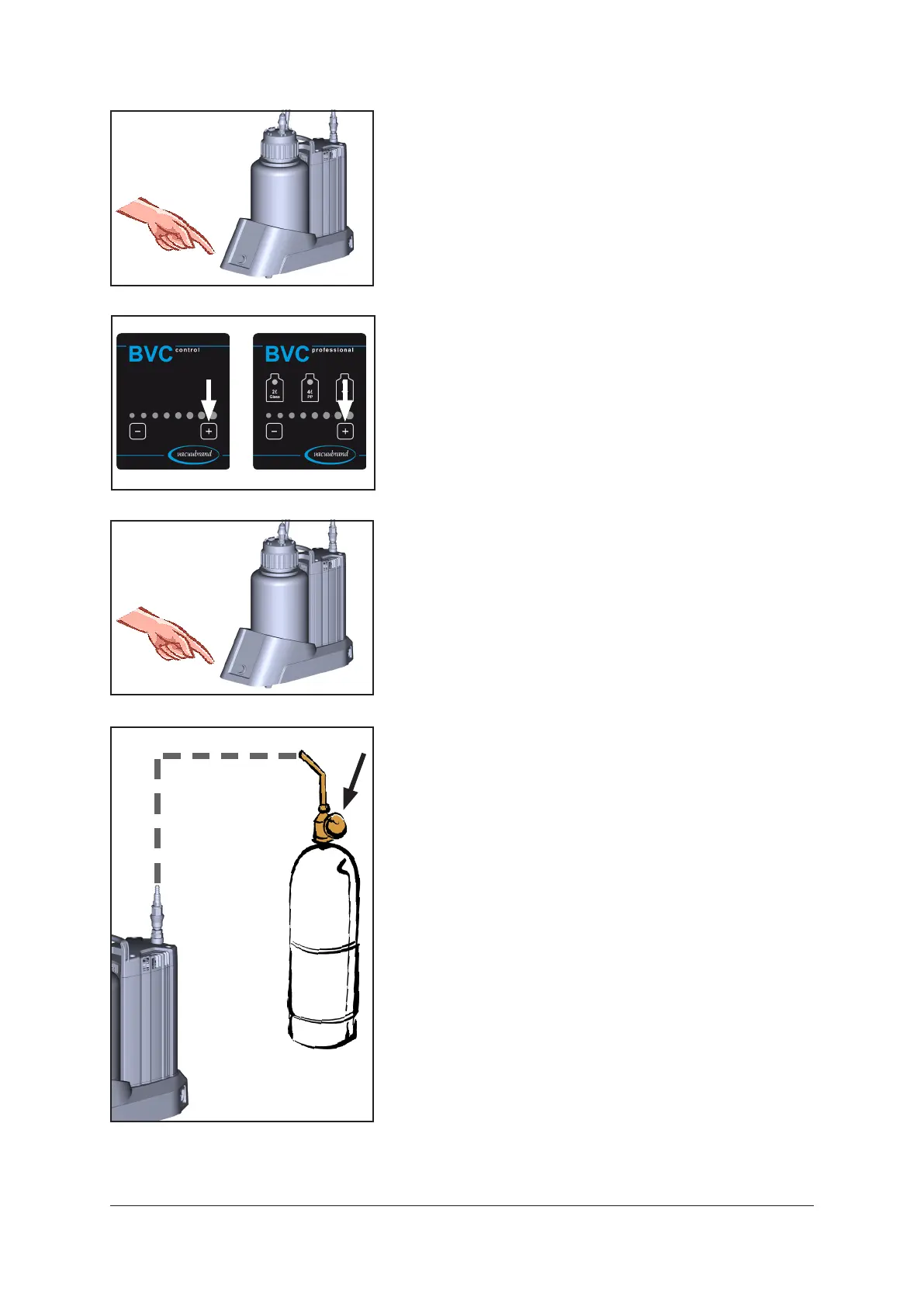

+ Max.pressureatthepumpinlet:1.1barabsolute.

➨ Openvalveatthegaspressurebottle.

+ Attention:Gasmayowattheoutletofthepump.

+ Comply with exposure time!

➨ Whenthepumpstops,switchofftheBVC.

➨ SettheBVCtomaximumsuctionpowerusingkey„+“.

max1.1barabsolute

➨ SwitchontheBVC.

Loading...

Loading...