Establishing operational readiness

32 ecoTEC plus installation and maintenance instructions 0020134823_01

9

1

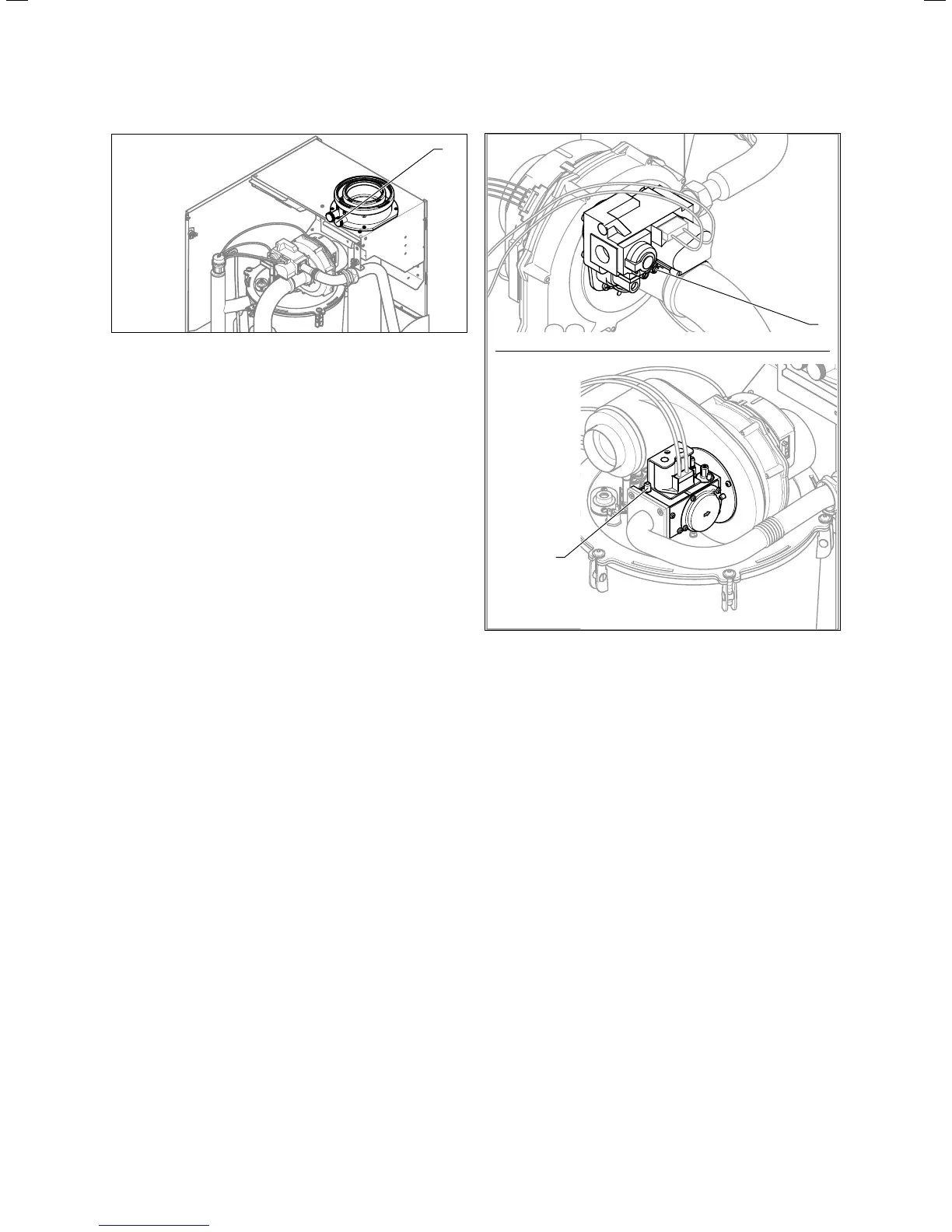

9.3 Flue gas and air analysis points

Key:

1 Flue gas analysis point

2 Air analysis point

> Use the air analysis point (2) to check for flue gas recir-

culation.

> Use the flue gas measuring instrument.

> If you discover CO or CO

2

in the fresh air, search for a

leak in the flue gas system or for flue gas recirculation.

> Eliminate the damage.

> Repeat the above-mentioned test to determine if the

fresh air contains CO or CO

2

.

> If you cannot eliminate the damage, you must not start

up the boiler.

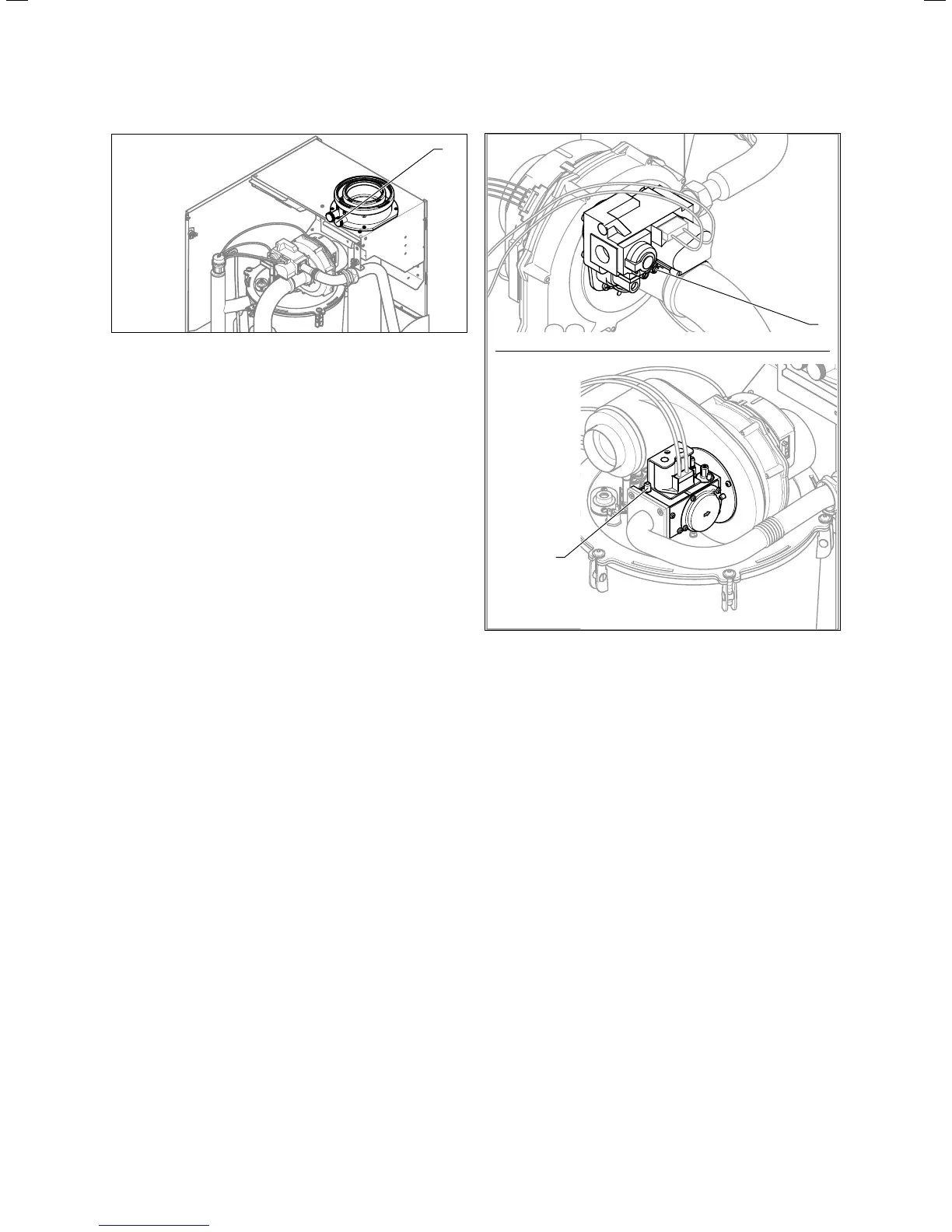

9.6.3 Checking the gas connection pressure

(gasflow pressure)

> Ensure that the gas connection pressure (gas flow pres-

sure) can be still achieved if all other gas-fired boilers in

the dwelling/house are in operation.

> Remove the front casing from the boiler (¬section4.6).

> Close the gas isolator cock of the boiler.

i

Permissible gas connection pressure (gas flow

pressure) for natural gas operation:

2 kPa (20mbar) to 2.5kPa(25 mbar)

1

1

806/5-5

1206/5-5

1006/5-5

9.4 Measuring the gas connection pressure (gas flow pressure)

> Undo the sealing screw of the measuring nipple (1)

(lower screw) at the gas valve using a screwdriver.

> Connect a digital pressure gauge or U tube manometer

to the measuring nipple (1).

> Open the gas isolator cock of the boiler.

> Start the boiler by activating check programme P.1, as

described in ¬section14.4.

> Turn the room thermostat fully up to that the maximum

heat in the heating installation can be shown.

> Measure the gas connection pressure in comparison with

atmospheric pressure.

Loading...

Loading...