Inspection and maintenance

46 ecoTEC plus installation and maintenance instructions 0020134823_01

13

13.1.3 Checking the CO

2

content

The CO

2

content must be checked/set in the following

cases:

– When replacing the gas valve

– If you suspect incorrect combustion.

– At initial start-up

– During any maintenance work

– When replacing the fan or burner

– If there are changes to the gas installation

1

13.1 Checking the CO

2

content

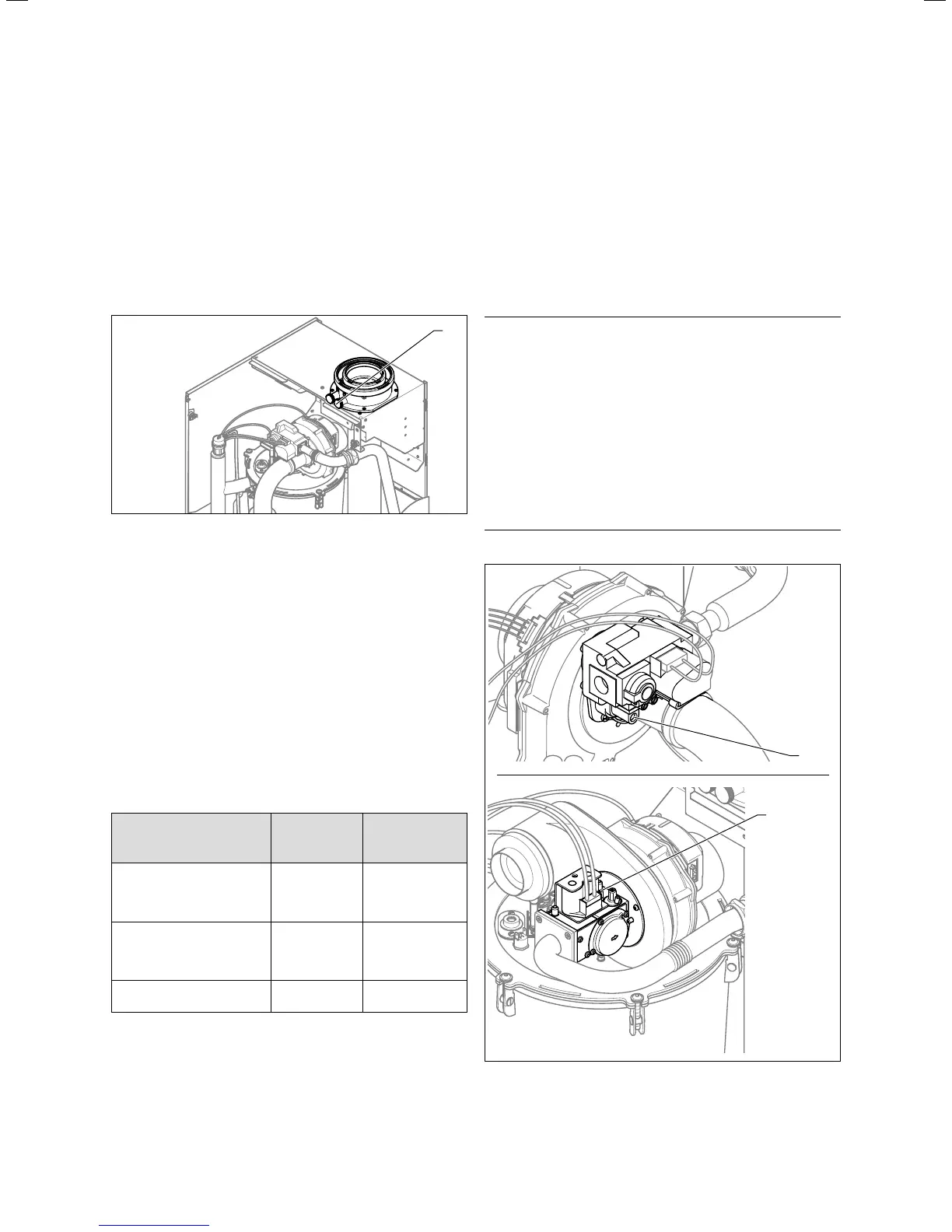

i

The boiler is equipped with a flue gas analysis

point (1). A suitable flue gas measuring instru-

ment can be used to check the combustion per-

formance of the measuring instrument at this

analysis point.

> Remove the front casing (¬section4.6).

> Start check programme P.1 (¬section11.4).

> Wait at least 5 minutes until the boiler reaches its

operating temperature.

> If required, remove the upper casing.

> Measure the CO

2

content at the flue gas analysis point

(1). Compare the measured value with the corresponding

value in ¬table13.1.

Settings Unit

Natural gas H

Tolerance

CO

2

after 5 minutes full load

operation with front casing

closed

Vol.-% 9.0 +/- 0.5

CO

2

after 5 minutes full load

operation with front casing

removed

Vol.-% 8.8 +/- 0.5

Set for Wobbe Index W

0

kWh/m

3

15

13.1 Gas default settings

> If all these points meet the requirements, continue in

accordance with ¬section 13.2.

> If one of the flue gas values is above the permissible

value in ¬table13.1, continue in accordance with the

following ¬section 13.1.4.

13.1.4 Setting the CO

2

content (or setting the air

ratio)

a

Danger!

Increased risk of poisoning from incor-

rect setting.

If one of the flue gas values is above the

permissible values in ¬table 13.1:

> Check that the entire flue gas system is

in good condition.

> Check that the seals of the combustion

system are in good condition.

> Check the gas connection pressure (gas

flow pressure).

> Check the gas volume flow.

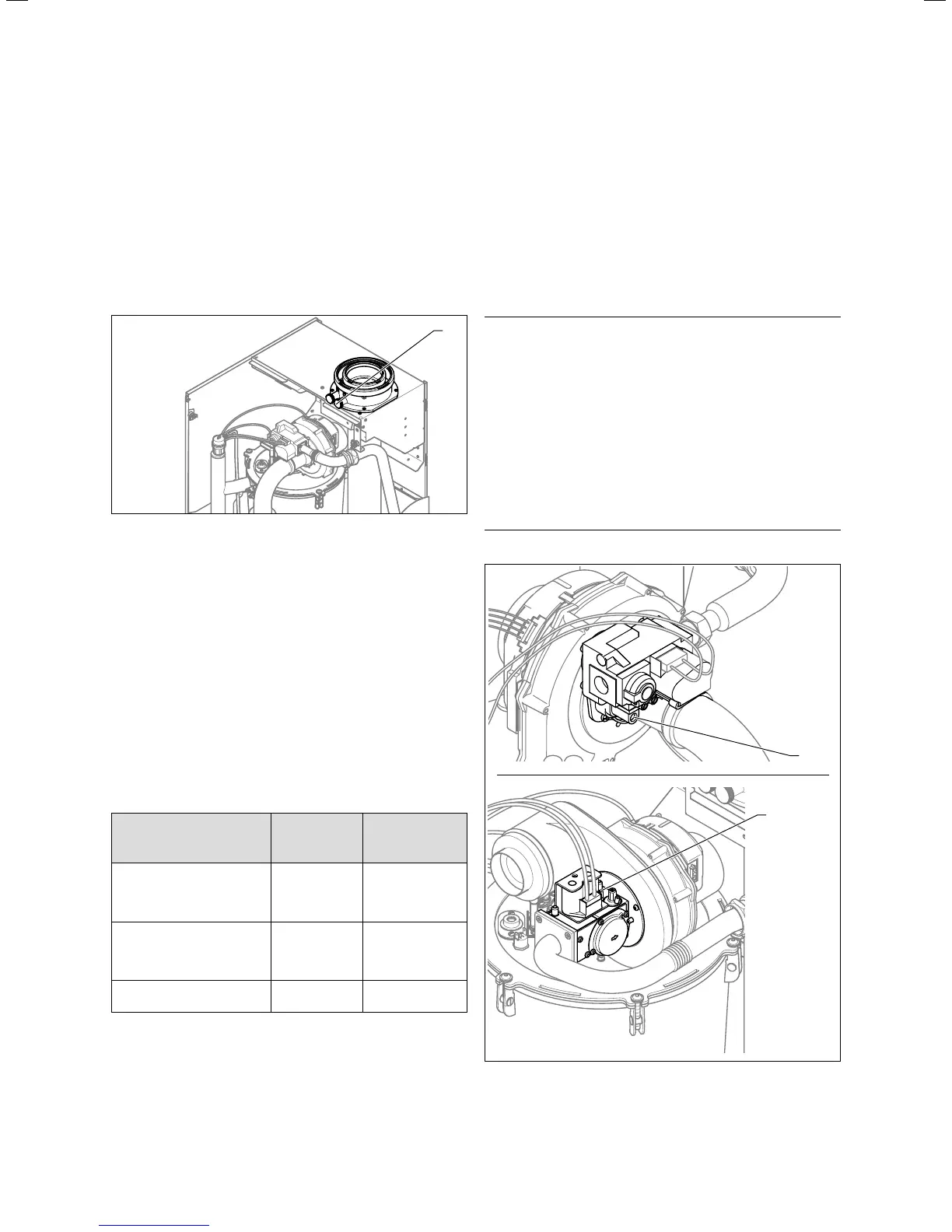

1

1

806/5-5

1006/5-5

1206/5-5

13.2 Carry out the CO

2

measurement, air index setting

Loading...

Loading...