Temperature Compensation Correction Curve

You can define temperature compensation correction

curve for Valmet MCA if you notice temperature depend-

ency in the measurement results.

Define the correction curve by entering 2 - 6 pairs

of temperature/consistency points. Based on the curve

drawn from these points, Valmet MCA subtracts the

curve consistency from the measurement results.

Determine the correction curve pairs of points as

described in section 9.1. Then enter the pairs of points

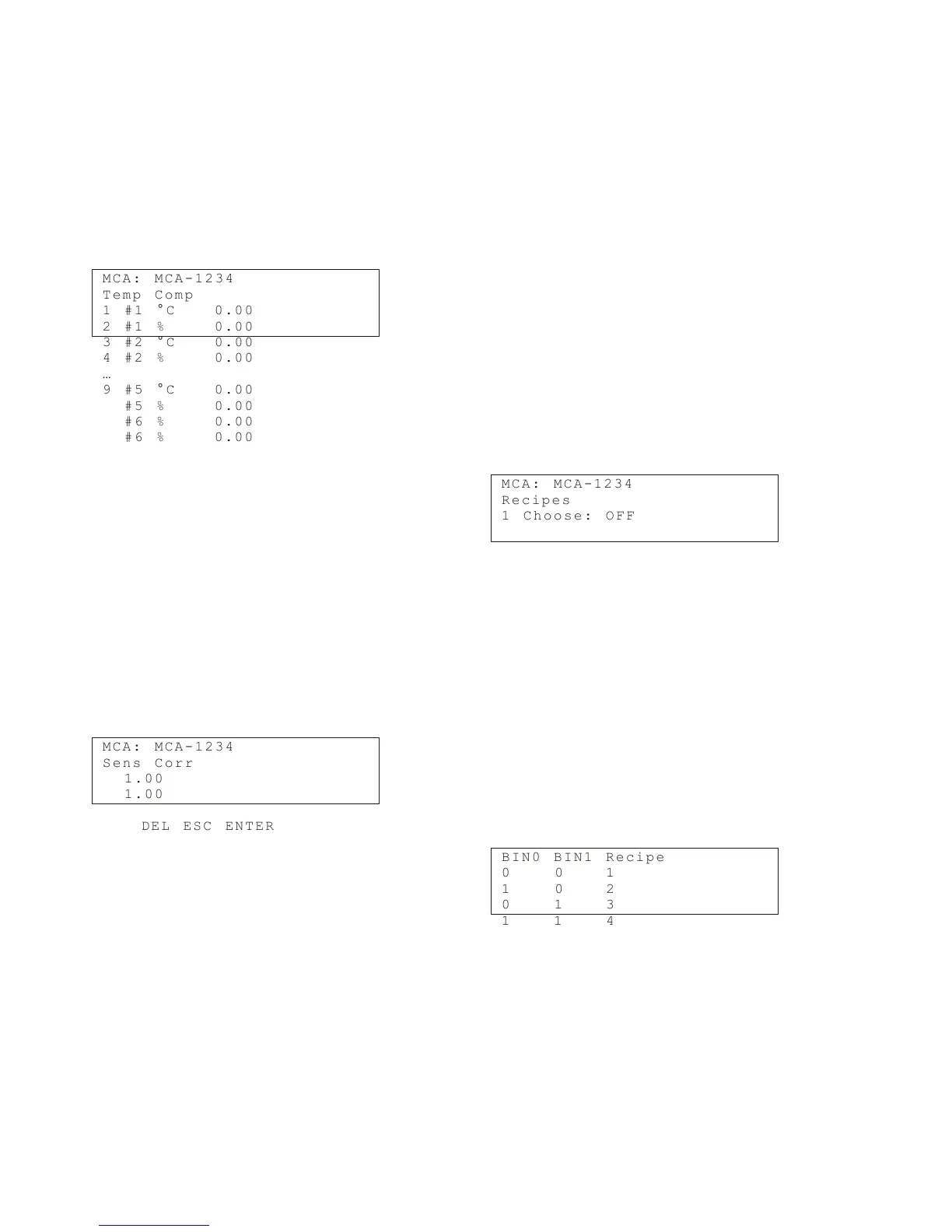

in the menu Temp Comp., which appears as follows:

M C A : M C A - 1 2 3 4

T e m p C o m p

1 # 1 ° C 0 . 0 0

2 # 1 % 0. 0 0

3 # 2 ° C 0 . 0 0

4 # 2 % 0. 0 0

…

9 # 5 ° C 0 . 0 0

# 5 % 0. 0 0

# 6 % 0. 0 0

# 6 % 0. 0 0

Enter temperature and consistency values for the

desired points (#1 - #6). Then press SEND (F2) to send

the values to Valmet MCA.

Sensitivity Correction

Valmet MCA consistency sensitivity is set according to

the wood fiber. The measurement sensitivity can be

changed if necessary, e.g. if you are measuring some

material other than wood fiber.

If you do not know the sensitivity correction of the

material beforehand, you can determine it according

to the instructions in section 9.2 and enter it in the Sens.

Corr. menu.

M C A : M C A - 1 2 3 4

S e n s C o r r

1 . 0 0

1 . 0 0

D E L E S C E N T E R

Recipes

The Recipe function may be necessary in special

functions in which measurement conditions change so

much that one calibration cannot cover it.

Such a change may be e.g.

– A change in consistency greater than the device

measurement range ( 9 - 15 % depending on the

type of sensor).

– A change in the measured material, since different

materials have different consistency sensitivity.

– A large chemical fluctuation (e.g. change of chemical

type) that cannot be compensated for with chemical

compensation.

In these cases, each process condition has its own

calibration and configuration performed.

This calibration and configuration is saved as its own

recipe. In addition to consistency calibration, for each

recipe you can set chemical compensation, temperature

consistency correction, sensitivity correction, and cur-

rent output scaling. You can save a maximum of four

recipes.

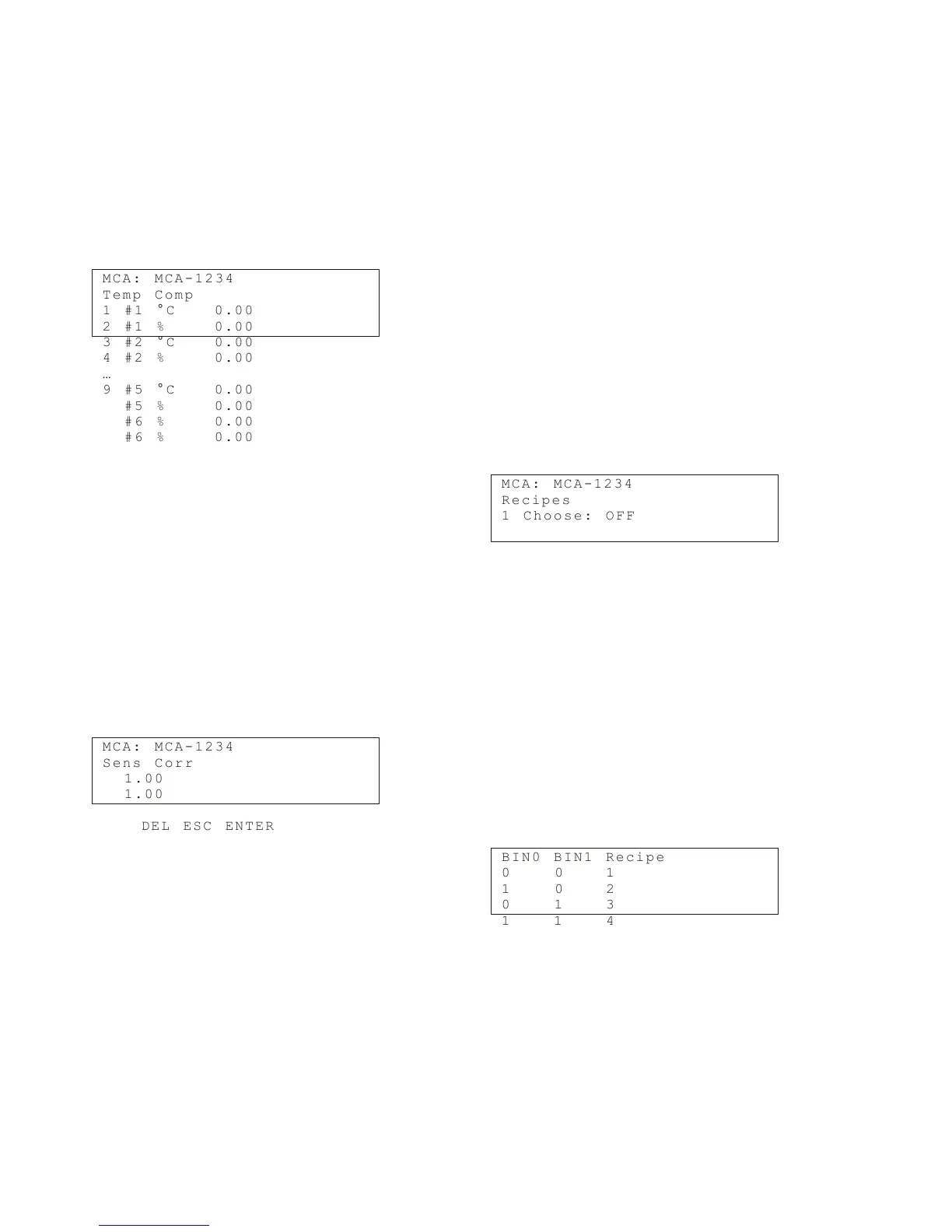

The Recipes menu is as follows:

M C A : M C A - 1 2 3 4

R e c i p e s

1 C h o o s e : O F F

In Choose, set the desired recipe number. The op-

tions are as follows:

– OFF: the recipe function is not in use (default),

– 1, 2, 3, 4: select the recipe number,

– BIN: select the recipe according to binary input.

Select the recipe. Then perform recipe calibration

and current output scaling. Begin using the recipes as

follows:

When you use the recipe selection method ‘BIN’,

connect the automation system digital control lines to

the TCU connector casing binary inputs BIN0 AND

BIN1. Connect their grounded line to BINGND. Select

the recipe with the digital output lines according to the

following table:

B I N 0 B I N 1 R e c i p e

0 0 1

1 0 2

0 1 3

1 1 4

Installation & Owner’s manual OUL00298 V2.3 EN

56

Valmet Mircowave Consistency Transmitter

Loading...

Loading...