10. Troubleshooting

NOTE: Before disconnecting the sensor or the flow-

through antenna, check that the process pipe is empty

and unpressurized and that disconnection is safe.

Valmet MCA does not require scheduled maintenance.

The instructions in this chapter refer to fault conditions.

10.1. Troubleshooting

Valmet MCA's self-diagnostics monitors certain internal

measurements and generates error messages if the

measurements exceed alarm limits. Self-diagnostics

also detects definite faults, which are often caused by

sensor electronics.

An erroneous measurement result may also be due

to antenna leakage, contamination, a fault in the an-

tenna cable, or a process variable that is skewing the

measurement. Self-diagnostics may not detect such a

fault.

The fault may also be in the current output sent by

the TCU. In this case, the measurement is correct, but

the current output sent to the automation system is in-

correct.

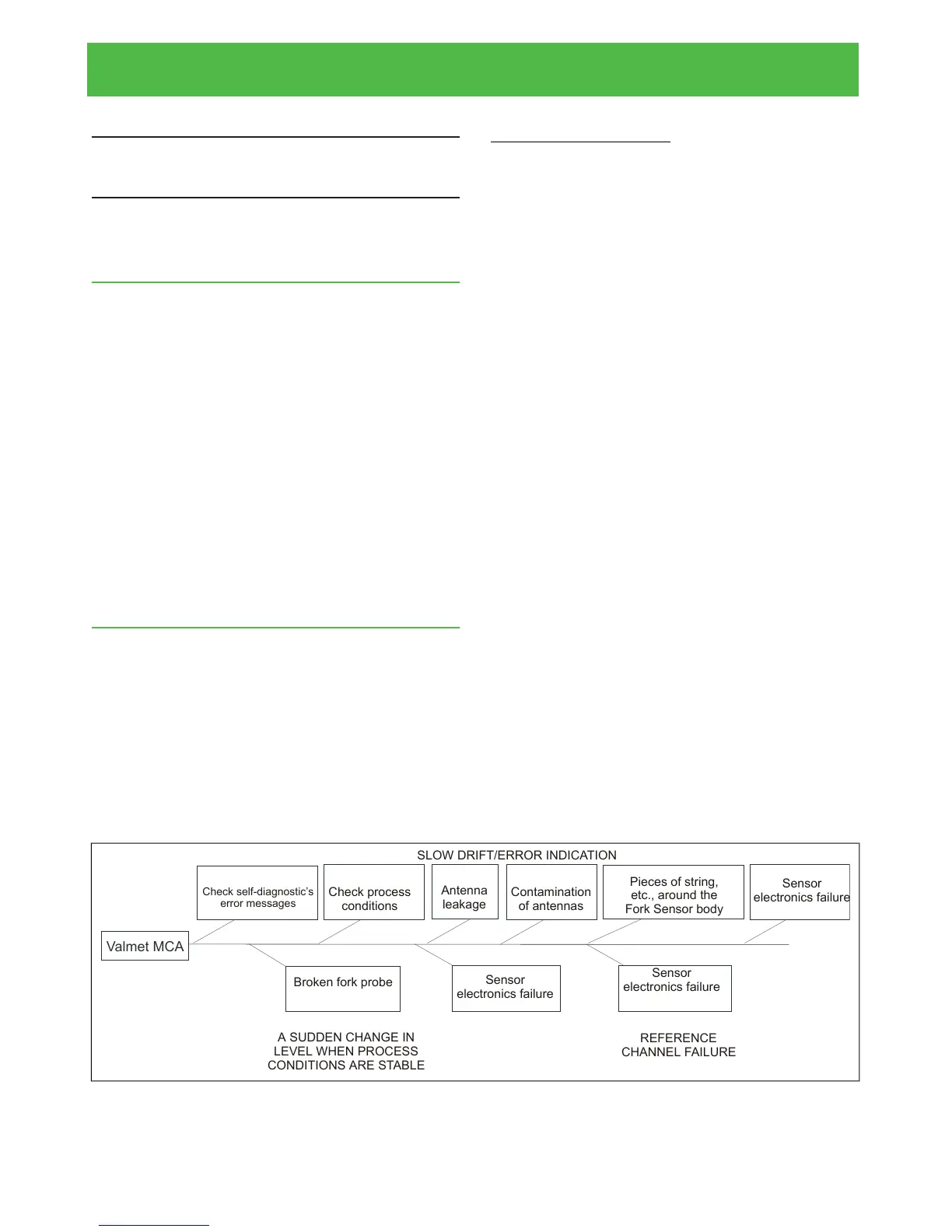

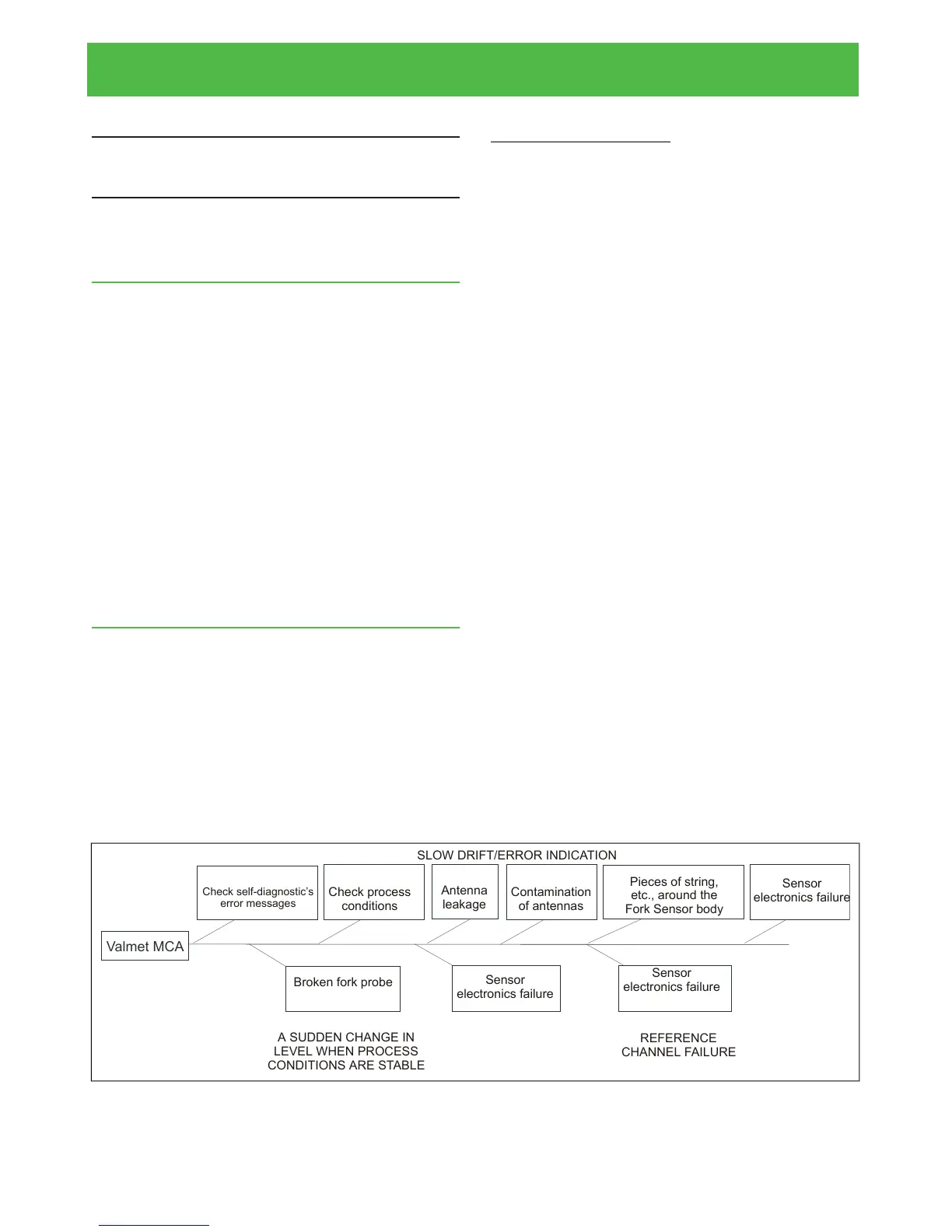

The following figure 1 contains a troubleshooting

chart for faults that appear in different ways.

10.2. Process Conditions

• Air

Air in the pulp is seen in measurements as an excess

in consistency. Air exists as bubbles of different sizes.

Small bubbles dissolve in water at pressure of approx-

imately 1.5 bar, but large bubbles may disturb pro-

cesses even at pressures higher than that. At most,

the error caused by air may be in the range of several

percentage points (percentage of consistency). Air

causes disturbances to the process itself, so the form-

ation of air bubbles should be avoided.

Air formation mechanisms

– Air is mixed with pulp, for example, when it is

dropped into the stock tank. If the level in the stock

tank is low, if the point of impact in near the pump,

or if the flow-through time in the tank is low, then air

is not able to escape properly from the pulp before

the pulp is forced into a departing flow. The best way

to put pulp in the tank is to run the input pipe under

the level of pulp in the tank.

– In addition, a strong stirring at a low surface level

can cause a whirl that causes air to be mixed into

the pulp.

– Air may also become mixed into the pulp through a

leaking joint on the pump's intake side.

– The dilution water may also contain air and cause

air bubbles in the pulp.

– Air can build up in bends in dilution or pulp pipes if

the bends are at the highest spot in the production

line. In such cases, an air pocket is formed and

continues to grow in a bend in a pipe. When the air

pocket is large enough, it begins moving with the

flow in the pipe. An air mass such as this may cause

a momentary error in consistency measurements.

– Air may be generated in the pulp through foaming

caused by chemicals as well.

Loading...

Loading...