BDR-720 Adela PRO

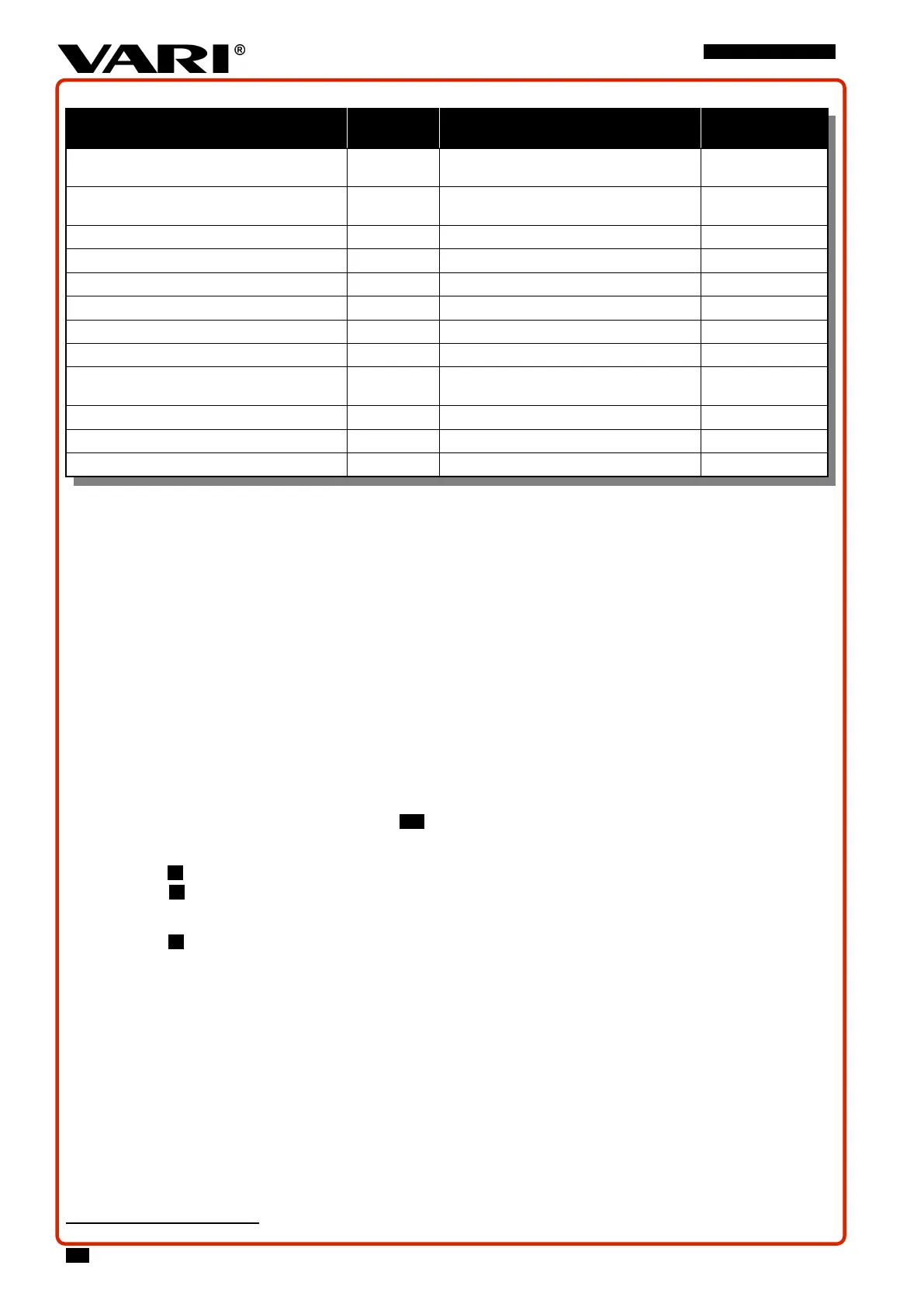

3.5.2 SERVICING INTERVALS

Activity Before

mowing

During the season Before storage

Checking engine oil level Check Per the engine operating instructions, interval

for dusty environment

Yes

Engine air filter cleaning Check Per the engine operating instructions, interval

for dusty environment

Yes

Washing - As needed Yes

Removing dirt and mowed growth debris - After every mowing Yes

Blade sharpening - As needed Yes

Blade inspection and storage Check Immediate replacement upon damage Yes

Checking that the cutting disc is tightened Check - Yes

Checking tightening of screwed connections Check Every 5 hours Yes

Check of the automatic cutting disc brake

function

Check Every 10 hours Yes

Check of the travel brake function Check Every 10 hours Yes

Lubrication Check

Table 37 Table 37

V-belts check - Every 20 hours Yes

Table 36: Servicing intervals

3.5.3 MACHINE LUBRICATION

When working with lubricants, observe the basic hygiene regulations and observe the environmental protection

regulations and laws.

For trouble-free and easy movement of all mechanical parts, pay sufficient attention to lubrication.

3.5.3.1 ENGINE OIL CHANGE

If you are not manually skilled enough, entrust this work to a specialist workshop.

• Follow the engine operating instructions for the type, quantity, and method of engine oil changing.

• Standard interval of oil change, specified by the engine manufacturer, reduce it by half. When mowing grasslands, a large amount

of dust and pollen particles is always produced.

3.5.3.2 TRANSMISSION OIL LEVEL CHECK

• The oil filling – see

Table

31

on page

42

- does not need to be changed throughout the service life of the transmission.

For any potential replenishment or change

83

of the oil filling only use the specified specification, using oil of another specification

reduces the service life of the transmission and exposes you to potential issues with its functionality.

• To measure the level, use the engine oil dipstick - 19 on

Fig. 1

. The machine must stand on a horizontal surface - garage or

workshop is ideal.

1) Wipe the dipstick thoroughly from the engine oil.

2)

Fig. 17

A Pull out the rubber plug of the inspection and filling hole - left of the shift lever foot.

3)

Fig. 17

B Insert the dipstick into the hole at the angle of about 30° to the chassis wall and parallel to the longitudinal axis of

the machine. Slide it all the way in, do not press hard on the dipstick. When measuring the oil level, the dipstick must rest on the

front and rear edges of the hole.

4)

Fig. 17

C The correct oil level is reached, when the oil mark on the dipstick is visible just at the collar, the distance is about 20

mm from the end of the dipstick.

5) Before returning the dipstick to the engine, wipe it thoroughly of any residual transmission oil and dirt.

83

When changing the transmission oil, the transmission must be removed from the machine. Always entrust this activity to an authorised service centre.

48

Loading...

Loading...