Series 642 INSTALLATION

742280ED Edition 2017-11-24 55/

1.2 Optimizing P gain

WE start by setting the P gain to 1.0 as a trial value and adjust according to the response.

The pump down routine has to be controlled as follows:

Move control valve into close position

Start pump down by opening the pump isolation valve or starting the pump and sending the first pressure

set point to the valve controller. With the example above, the first pressure set point is 510 Torr.

At each new interval (exceeding 10 sec) send the new pressure set point.

Repeat until process pressure is achieved.

While pumping down chamber pressure and valve position should be data logged to compare the actual

pump down curve with the ideal straight pump down line.

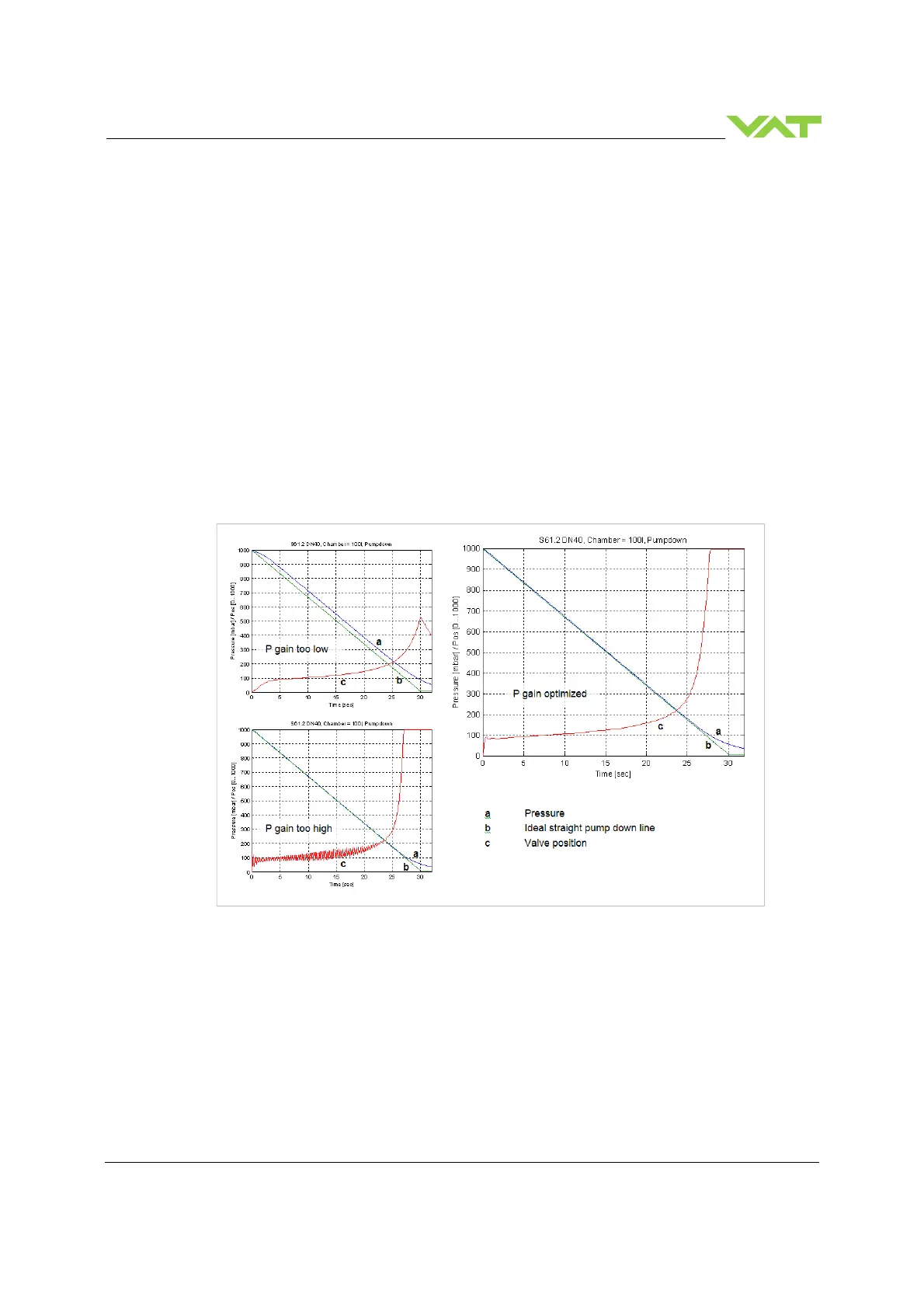

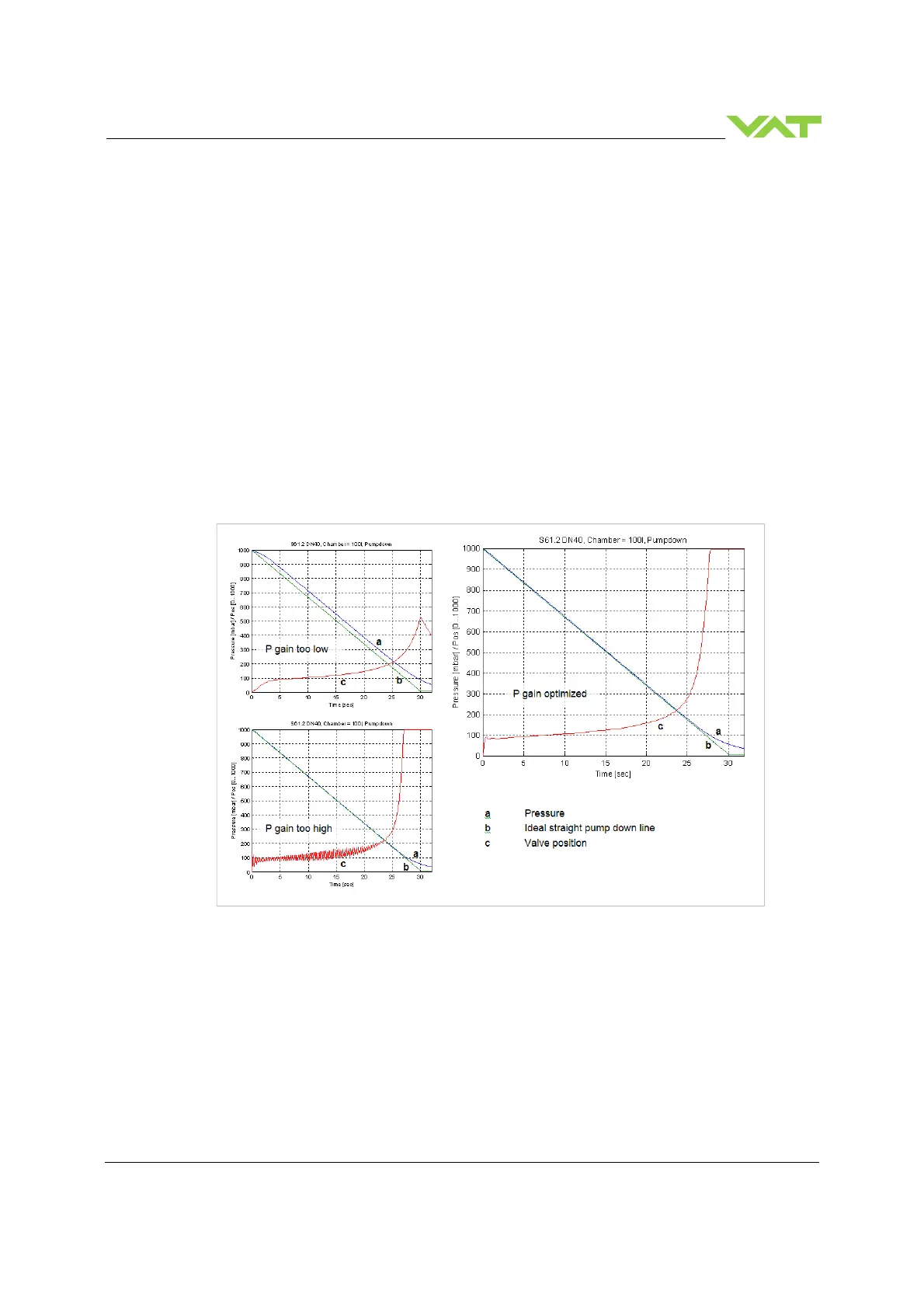

If the pressure follows the ideal pump down line with significant delay, the P gain is too low.

If the pressure oscillates around the ideal pump down line or if the valve position oscillates, P gain is too

high.

P gain is optimized if the pressure follows the ideal pump down line closely and the valve position is not

oscillating at all.

Example:

Required information for support:

• Go to ‘Tools / Create Diagnostic File’ in ‘Control View’ resp. ‘Control Performance Analyzer’ and save

file

• Pressure / flow / gas conditions to be controlled

• Chamber volume

• Pumping speed (l/s) and pump type (e.g. turbo pump)

• System description

• Problem description

Send diagnostic file with and all required information to tuning-support@vat.ch

Loading...

Loading...