7

VEGAPULS 6X

1022892-EN-240312

4 Specicconditionsofuse("X"identication)

The following list describes the special operating conditions of VEGAPULS 6X.

•

In the application the following applies to the radar sensors VEGAPULS 6X in the versions with

Aluminium/Titanium:

– Installation must be carried out in such a way that the generation of sparks as a result of impact

and friction processes between Aluminium/Titanium and steel is excluded. This excludes stain-

less steel without rust particles.

•

Certain components of the radar sensor VEGAPULS 6X can charge electrostatically. These

include: Plastic housings, non-grounded metal parts, plastic antennas. For details, refer to chap-

ter "Electrostatic charge (ESD)" of these safety instructions.

•

To avoid the risk of electrostatic charging of metal parts, the VEGAPULS 6X must be connected

to the potential equalization (transition resistance ≤ 1 MΩ).

•

All parts of VEGAPULS 6X in contact with the medium must only be used in such a medium

against which the materials are suciently resistant.

•

VEGAPULS 6X with rinsing connection: It must be ensured that the IP67 degree of protection is

provided at the connection to the reux valve when used as zone 0/1 (EPL Da/Db) instruments.

After removing the reux valve or the rinsing facility on the refölux valve, the opening must be

closed with a suitable screw plug so that the IP67 degree of protection is maintained.

•

VEGAPULS 6X with swivelling holder: It must be ensured that the IP67 degree of protection is

maintained when operating as zone 0/1 (EPL Da/Db) instrument after aligning the antenna using

the swivelling holder and after screwing on the tension ange.

•

Ambient temperature

– You can nd the details in chapter "Thermal data" of these safety instructions.

5 Installation

•

The installation of the device must only be carried out by qualied personel.

•

The sta must be trained in explosion protection and familiar with the relevant valid regulations.

•

Make sure when working on the instrument that there is no explosive atmosphere present. The

supply circuits should be voltage-free, if possible.

•

Install the instrument in accordance with the manufacturer specication and the applicable

national regulations, e.g. planning and installation in accordance with IEC/EN 60079-14.

•

The devices must be integrated into the local potential equalization.

•

If grounding of the cable screening is necessary, this must be carried out acc. to the valid stand-

ards and regulations, e.g. acc. to IEC/EN 60079-14.

•

Close the housing lid (s) up to the stop before starting operating, to ensure the IP protection rat-

ing specied on the type label.

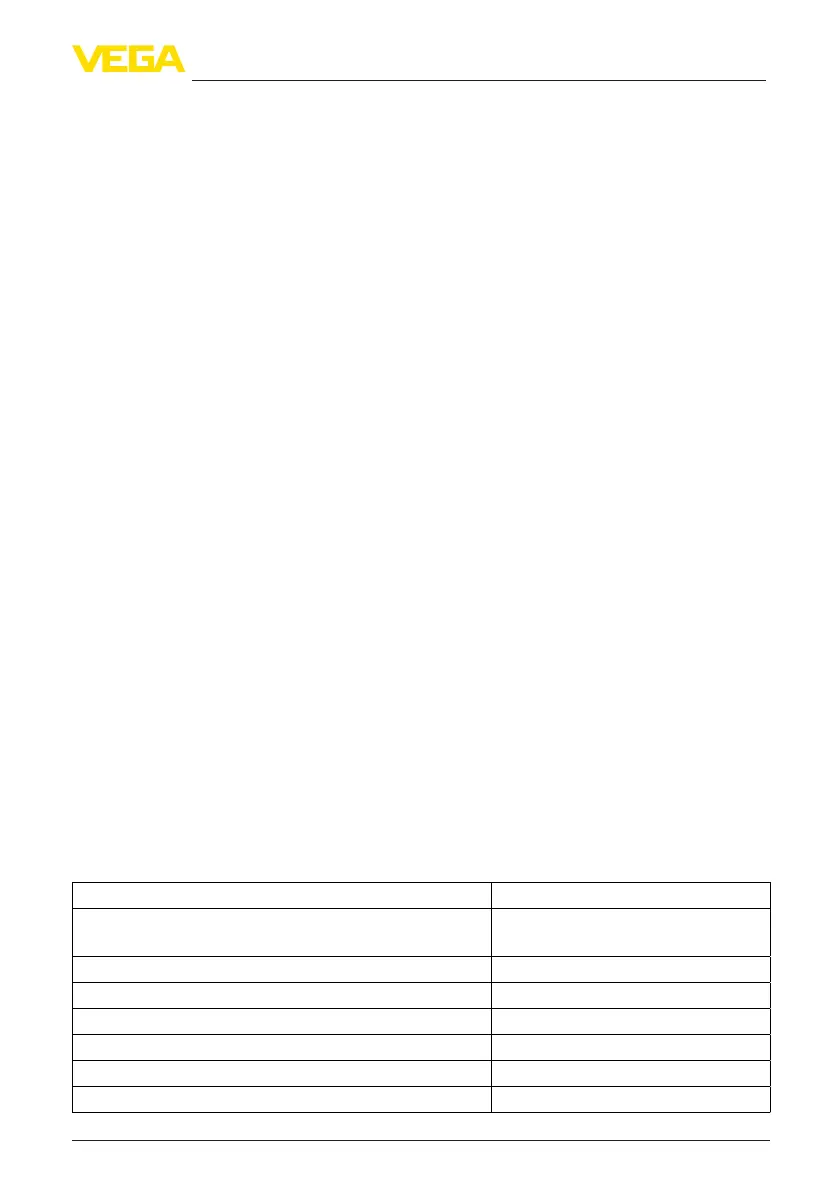

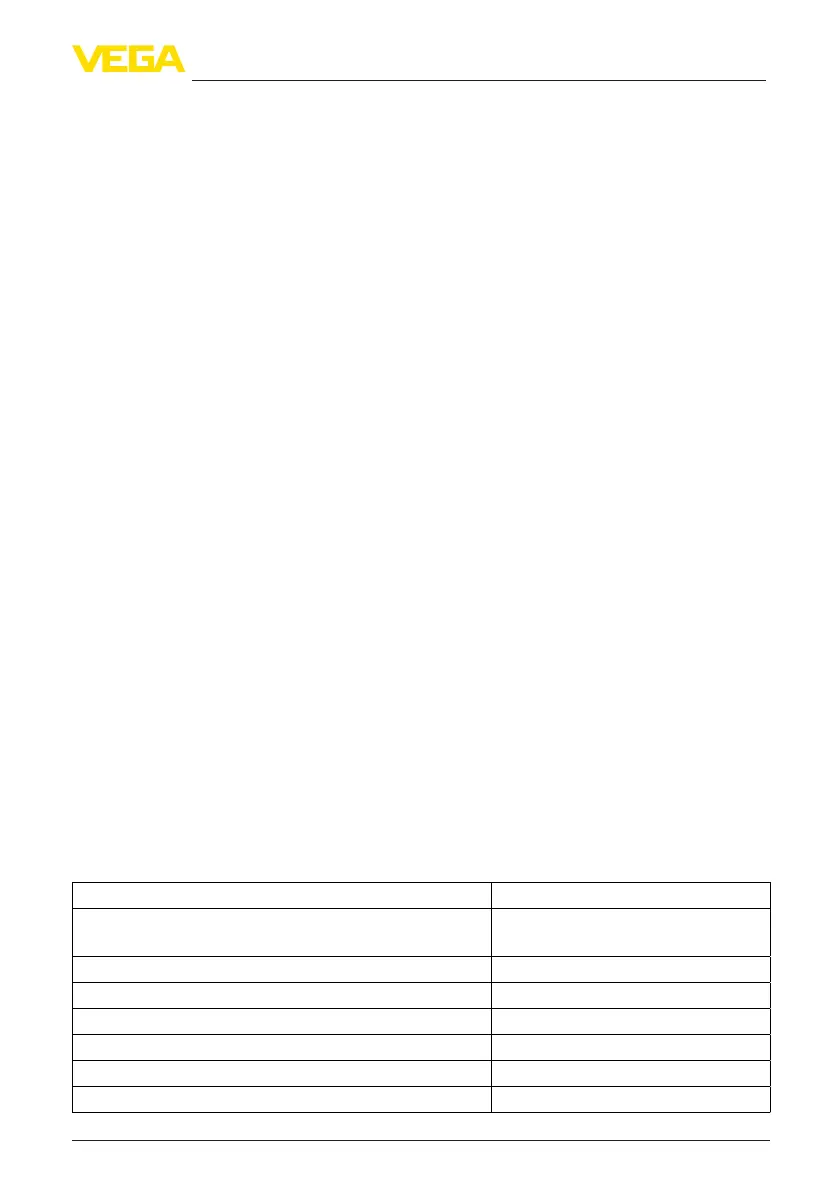

For device category 2 the following process pressures are applicable depending on the antenna

version:

Processpressure

Plastic horn antenna, with inspection window Compression ange -1 … +2 bar

Adapter ange -1 … +1 bar

Thread with integrated horn antenna, with inspection window -1 … +40 bar

Flange with encapsulated antenna system, with inspection window -1 … +25 bar

Flange with lens antenna, with inspection window -1 … +3 bar

Hygienic version with thread -1 … +25 bar

Hygienic version with tension ange or compression nut -1 … +16 bar

Horn antenna -1 … +100 bar

Loading...

Loading...