Ventis™ MX4 Product Manual

29 © 2014 Industrial Scientific Corporation

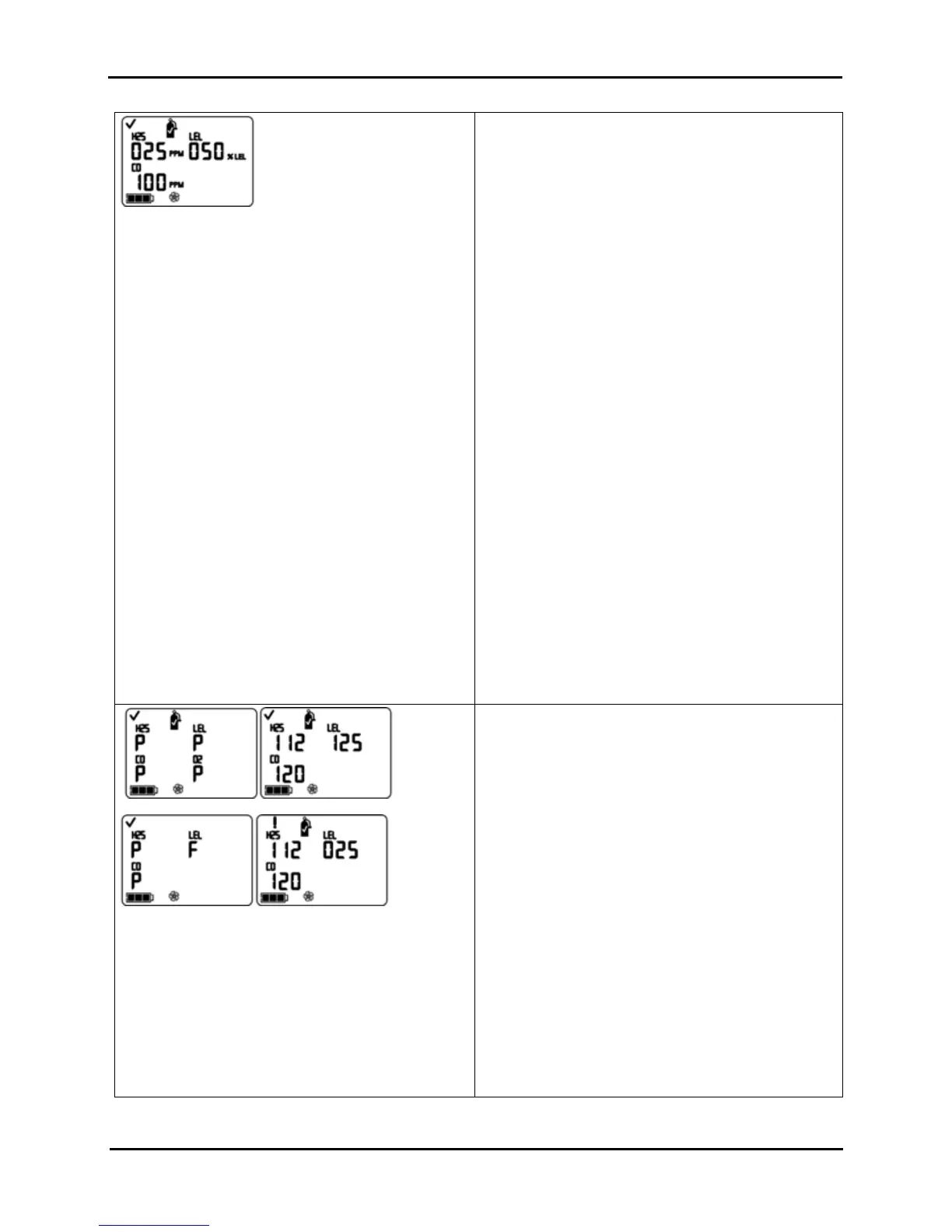

Calibration Apply Gas Screen*

The gas cylinder icon flashes. Each sensor’s display

shows the calibration gas concentration to be applied.

(The O

2

display is blank as the sensor was calibrated

during zeroing.) The monitor waits up to five minutes to

successfully sense the gas.

Calibration In-progress Screen*

If gas is sensed, the gas values for the LEL and

toxic sensors increase and the O

2

value decreases.

If gas is NOT sensed, a failed calibration registers

and the Calibration Failed Screen displays.

To Terminate

Press ON/OFF/MODE while the gas cylinder icon flashes

to terminate the quick calibration process (or to skip a

sensor’s calibration in standard calibration) and return to

the gas monitoring mode.

To Calibrate

From the already prepared gas cylinder, start the flow of

gas as noted below for the monitor/regulator combination

in use.

For an aspirated monitor with a demand flow

regulator, complete the tubing connection from the

regulator to the pump inlet.

For an aspirated monitor with a positive flow

regulator, turn (counterclockwise) the regulator’s

knob.

For a diffusion monitor with a positive flow

regulator:

Place the calibration cup over the upper portion

of the monitor’s case top (front of monitor). To

attach properly, complete or observe the

following.

o The cup fully covers the sensor ports.

o The monitor’s display and buttons are NOT

covered.

o The cup’s side arms fit securely in the

grooves on the sides of the monitor.

o The Ventis MX4 name on the calibration

cup is upright and readable.

o The cup’s nipple points up and away from

the monitor.

Turn (counterclockwise) the regulator’s

knob.

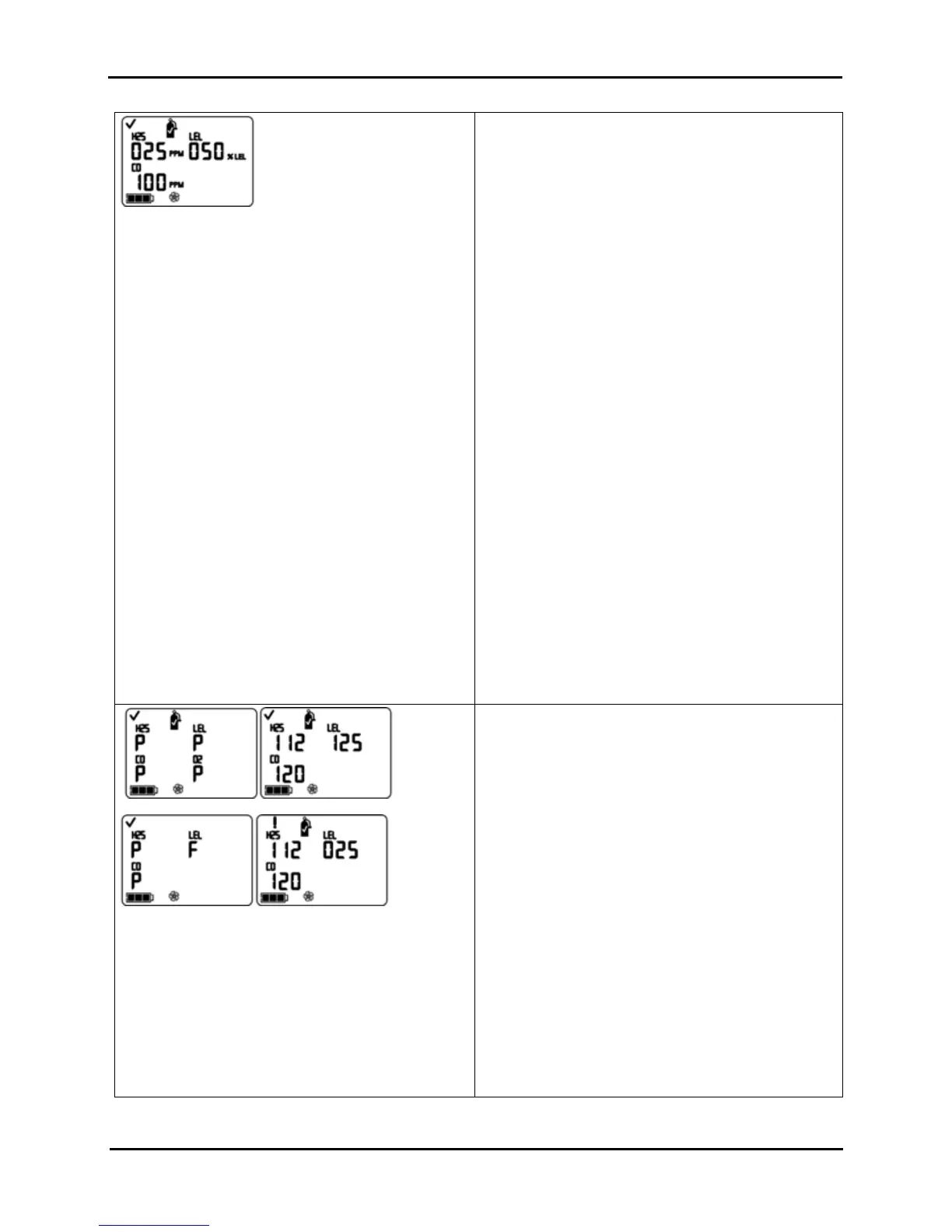

Sensor Results Screen*

Pass (top) or Fail (bottom) Screen

The display alternately shows a “P” for pass (or “F” for

fail) and the final span value reading for each sensor. A

check mark displays and a single beep sounds.

NOTE: The “span reserve” of a sensor measures its sensitivity. The

displayed span value divided by the calibration gas value equals the

span reserve percentage. A span reserve percentage of greater than

70% indicates a “good” sensor; 50%-70% indicates “marginal”

sensitivity. When the span reserve percentage is less than 50%, the

sensor will not pass calibration.

STOP THE FLOW OF GAS.

After calibration, or if calibration is terminated at anytime

during the process, stop the flow of gas as follows.

For an aspirated monitor with a demand flow

regulator, disconnect the tubing from the pump inlet.

For an aspirated or diffusion monitor with a

positive flow regulator, turn (clockwise) the

regulator’s knob.

All Sensors Pass

The user returns to the mode from which the calibration

process was entered (configuration or gas monitoring).

Sensor Fail

If one or more sensors fail calibration, the Calibration Fail

Screen displays and a system level alarm turns on.

Loading...

Loading...