8

English

Liebert HPM --- A/W/F/D/H

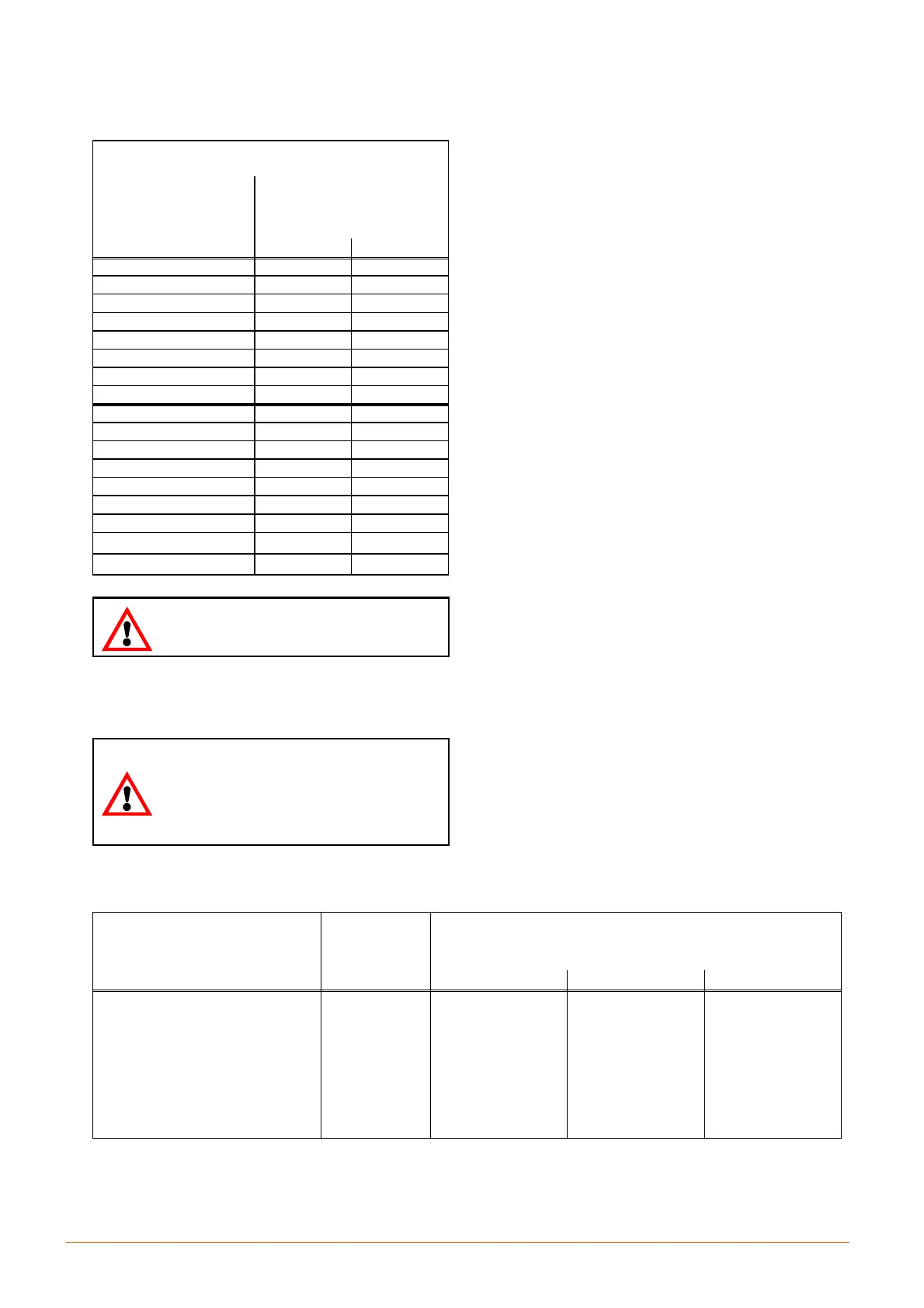

4.1.2 --- Pipe diameter

The diameters of the connecting pipes between the condi-

tioner and the condensing unit listed in Tab. c must be re-

spected, otherwise the guarantee becomes invalid.

Ta b . c --- Pipe diameters (room unit --- remote condenser)

STANDARD PIPE DIAMETERS

(Valid for equivalent lengths up to 50 m)

MOD.

copper tube

external diametre x thickness

[mm]

R410A

Gas Liquid

S0F 10 X 1 10 X 1

S0H 12 X 1 12 X 1

S1A 12 X 1 12 X 1

S1D 14 X 1 14 X 1

S1E 14 X 1 14 X 1

S1G 16 X 1 16 X 1

S2E 18 X 1 16 X 1

S2G 22 X 1.5 18 X 1

M2H---M3A 22 X 1.5 18 X 1

M3F 16 X 1 16 X 1

M3G 22 X 1.5 18 X 1

M4E---M5B 22 X 1.5 18 X 1

M4H 18 X 1 16 X 1

M5C---M5D 22 X 1.5 18 X 1

M7L 22 X 1.5 18 X 1

L8F

28 X 1.5 22 X 1.5

L9H

28 X 1.5 22 X 1.5

Whenthepipesaremorethan50mlong,

contact Technical Support Department

4.1.3 --- Installing pipelines

THE FOLLOWING OPERATIONS MUST BE CARRIED OUT

BY AN EXPERIENCED REFRIGERATION TECHNICIAN.

The discharge operation of the room unit

pressurized with helium (at 1 bar) and the

de ---welding of the b ottoms from the

connections must be carried out as last

operations, immediately followed by the

connection and emptying of the whole

system.

1) Lay the piping, taking note of the follo wing:

S Welding:

S All joints must be braze---welded.

S Avoid butt welds by using sleeves or enlarging

one of the pipes using a pipe opener.

S Use silver---based solders and the correct appar-

atus.

S Guarantee a corre ct weld as a refrigerant leak, or

a faulty weld which leads to a leak later on, can

seriously damage the air conditioner.

S Always use large---radius curves (bending radius at

least equal to pipe diameter). Bend the pipes as fol-

lows:

S soft copper: by hand or bending device.

S hard copper: use preformed curves. Do not over-

heat the pipes when welding so as to minimize

oxidation.

2) Connect the pipes to the condenser:

S Condensers with butt---welded pipe connec tions:

cut the pipe, enlarge it and weld it to the pipeline.

S Condense rs with threaded tap connections: flange

the pipes and connec t.

RESPECT THE DIRECTION OF REFRIGERANT

FLOW (SEE LABELS ON REFRIGERANT CON-

NECTIONS).

3) Wash out the pipelines as follows:

a) Plug up the free ends of the pipes.

b) Connect a helium or nitrogen cylinder, fitted with a re-

ducer (max. pressure 10 bar), to the ¼” SAE

Schrader valve of the condenser.

c) Pressurize the pipes with helium or nitrogen.

d) Unplug the pipes instantaneously.

e) Repeat a) --- d) several times.

THIS OPERATION IS ESPECIALLY IMPORTANT WHEN

HARD COPPER PIPING IS USED.

4) Open all the room unit shut---off valve.

5) Discharge the room unit pressurized with helium (at 1

bar) opening the charge valves so that all the branches

of the circuit are discharged (e.g. on the receiver, on the

low pressure side and on the compressor delivery).

6) De---weld the bottoms from the

connections of the room

unit.

7) Fix (weld) the pipes to the connections on the air condi-

tioner.

8) Connect the refrigerant safety valve to the outdoor with

a copper pipe sized in order to satisfy the requirements

of EN13136 (i.e. till 10m length, i 26mm).

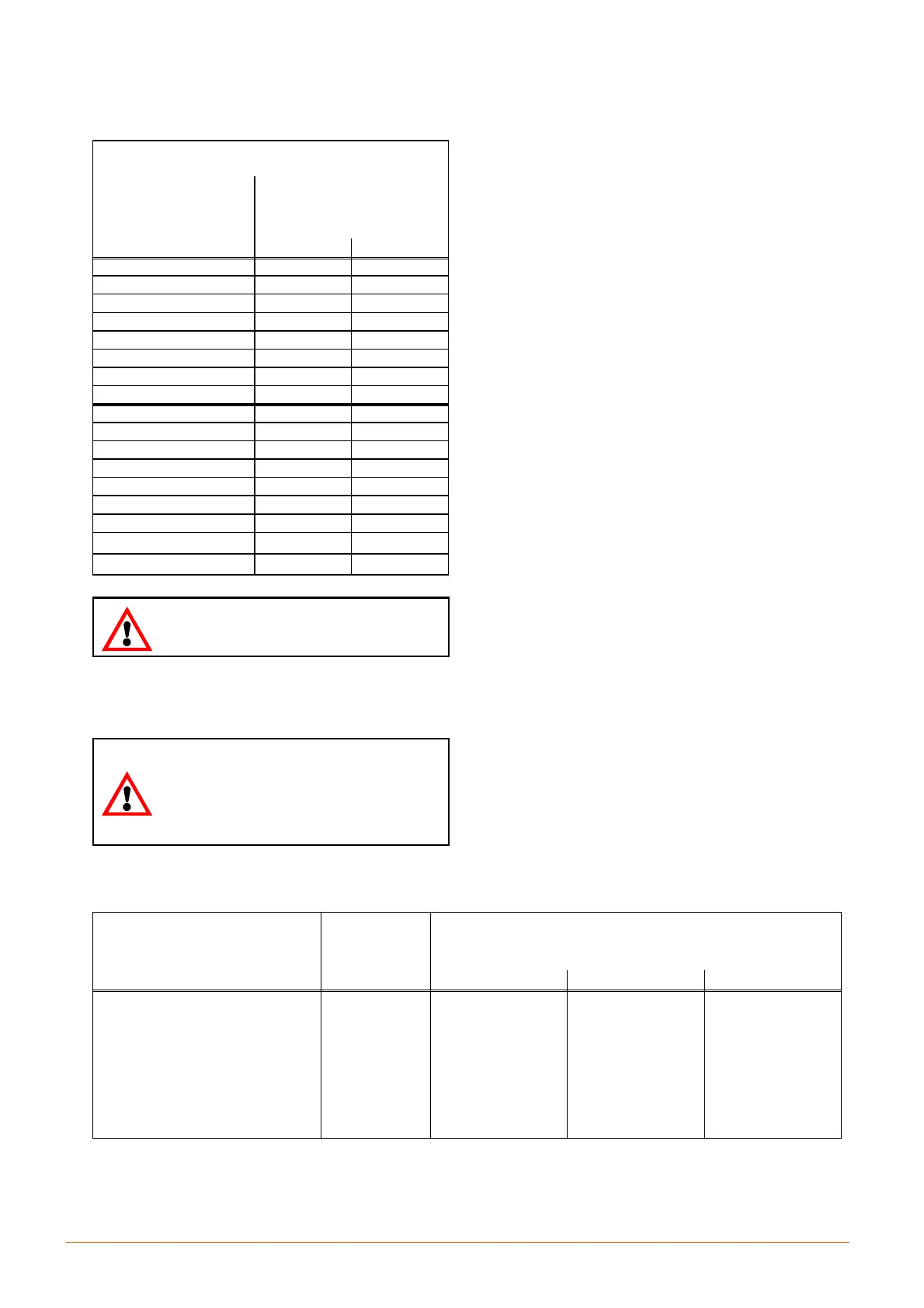

Tab. d --- Weight of refrigerant contained in piping during operation

EXTERNAL PIPE

DIAMETER

(mm)

gas (*)

liquid (+), at different condensing

temperatures

R410A (kg/m)

35.0 _C 46.0 _C 57.0 _C

10 x 1 0.0048 0.0507 0.0470 0.0426

12 x 1 0.0075 0.0793 0.0734 0.0665

14 x 1 0.0108 0.1142 0.1056 0.0958

16 x 1 0.0147 0.1554 0.1438 0.1304

18 x 1 0.0192 0.2030 0.1878 0.1703

22 x 1.5 0.0271 0.2862 0.2648 0.2402

28 x 1.5 0.0469 0.4956 0.4585 0.4158

(*) Due to the small weight influence (at 15.5 bar --- discharge temp. 65_C), only 0.062 kg/l for R410A is considereted.

(+) Liquid pressure and density varies according to condensing temperature (see refrigerant tables).

Loading...

Loading...