10

English

Liebert HPM --- A/W/F/D/H

condenser coil surface or limit its ventilating power to ob-

tain these conditions.

4) Charge the unit until the working conditions of the entire

refrigeration circuit have become normal.

5) Using a manometer, check that the evaporating temper-

ature is above 0_C.

5) Verify that the superheat is 5---8 K (to do this refer to para.

9.1).

4.3 -- Refrigeration circuits

See drawings in Enclosure E.

5 --- Water connections

5.1

-- General warnings

ENSURE T HAT THE T UBING D OES NOT OBSTRUCT THE

AIR FLOW(Under only).

IF THE TUBING IS TO RUN OUTDOORS, ADD ETHYLENE

GLYCOL TO THE CIRCUIT AS DESCRIBED IN PARA. 5.5.

5.2 -- Water connections

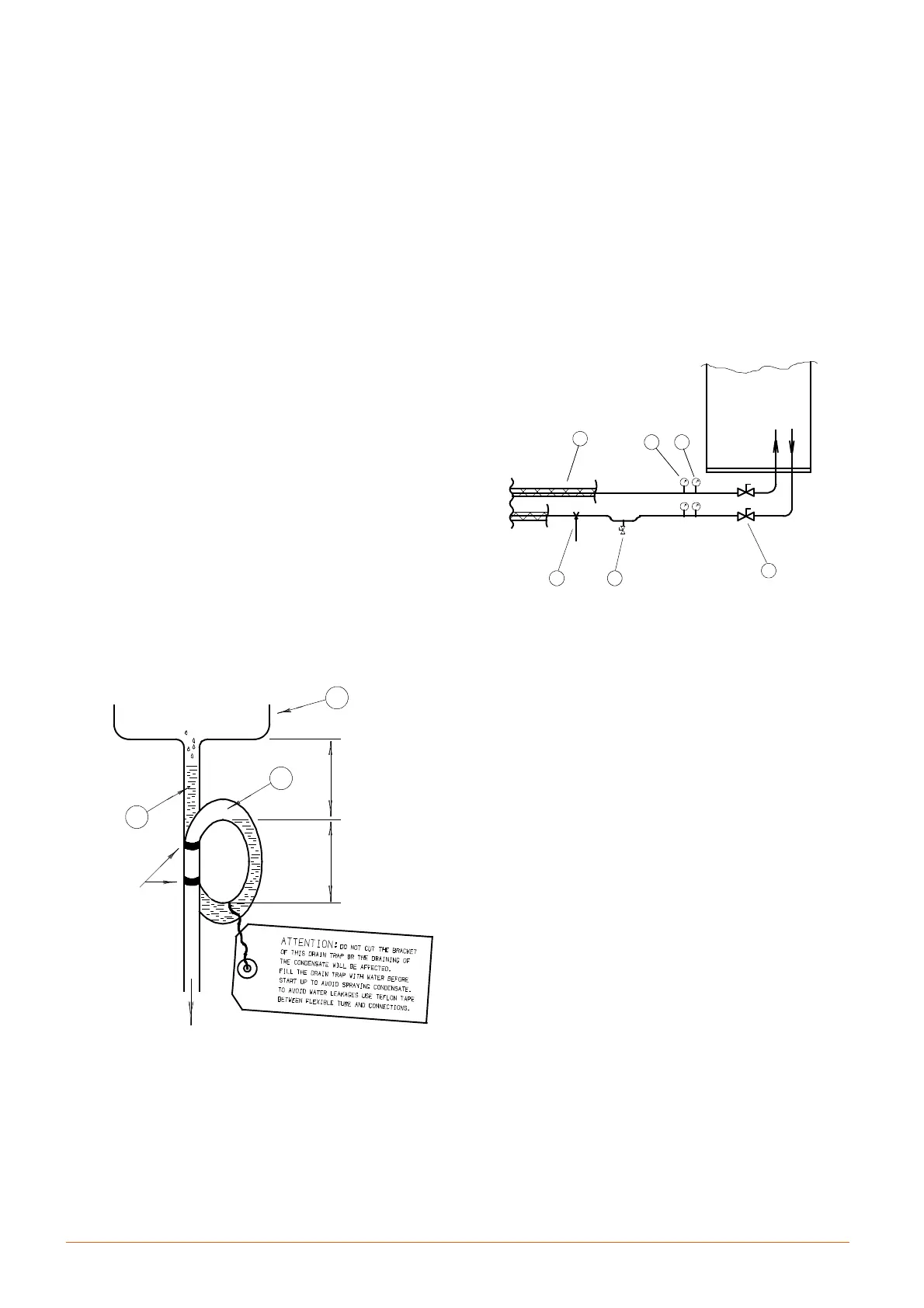

--- Condensate drain (Fig. c):

S Use galvanized steel, PVC or flexible polythene

tubing.

S Allow a 2% gradient towards the drain.

S There must be a drain trap (1) placed at least 20 cm

below the drain tray (2). In the units S13÷S23, Mxx

and Lxx the drain trap must be placed under the unit,

in the false floor.

S Fill the drain trap with water (3).

F i g . c --- C o n d e n s a t e d r a i n

BRACKET

to be

connected

by user

2

3

min.

1

20 cm

min.

10 cm

--- H u m i d i f i e r (optional):SeeEnclosure A.

--- H o t w a t e r (optional):

S Use copper or steel (Mannesmann) tubing.

S Insulate both tubes using Armaflex insulation.

5.3 -- Chilled water connections

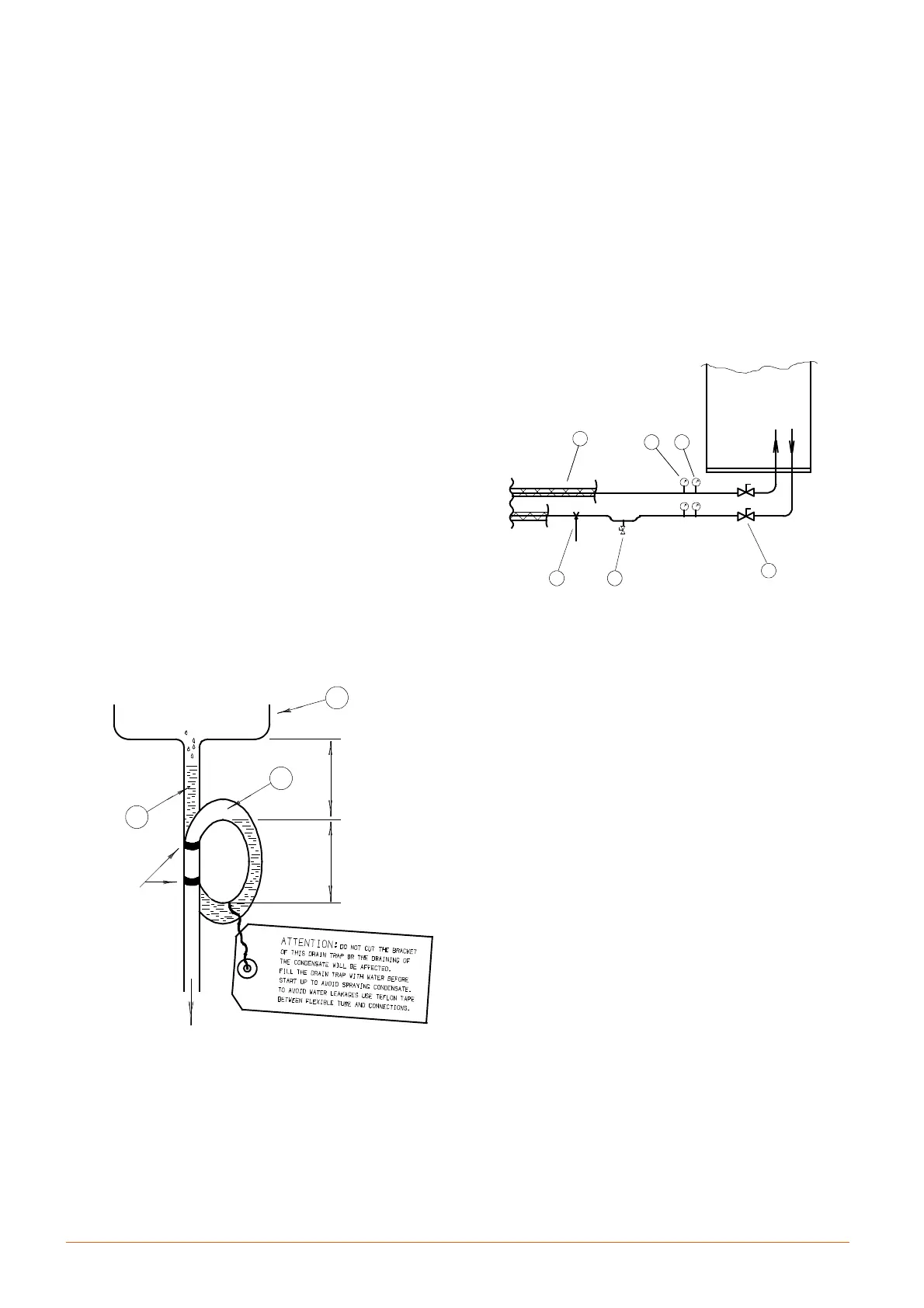

(D and H only) --- ( F i g . d )

S Use copper or steel (Mannesmann) tubing.

S Place the tubing on supporting saddles (1).

S Insulate both tubes using Armaflex insulation (2).

S Place shut---off ball valves (3) at the conditioner inlet and

outlet to allow easy maintenance.

S It is useful to install a thermometer (4) and a manometer

(5) at the conditioner inlet and outlet.

S Install a water drain tap (6) at the lowest point in the cir-

cuit.

S Join the threaded water connections. It is recommended

to use hemp and paste to get a reliable pressure ---tight

joint.

S Fill the circuit with water/glycol (see Fig. d).

Air

1 6

3

4 5

2

conditioner

F i g . d --- C h i l l e d w a t e r c i r c u i t

5.4 -- Cooling water connections (W, F and H only)

The unit must receive cooling water as follows:

a) from an external cooling water source, in open circuit

(para. 5.4.1 and Figures in Enclosures).

b) using a Dry cooler, in closed circuit (para. 5.4.2).

S Connect the piping as shown in Enclosures D.

S It is advisable to use hoses to be connected, with

3---piece joints, to the condenser water inlet and outlet

couplings.

S IMPORTANT: fit a standard strainer on the inlet water pip-

ing.

S Place shut---off ball valves at the conditioner inlet and

outlet to allow easy maintenance.

S It is advisable to install a water drain system at the lowest

point in the circuit.

S Fully drain the piping before connecting it to the air con-

ditioner.

5.4.1 --- Notes for open circuit applications

S Use the unit with mains or well water.

DO NOT USE WATER FROM AN EVAPORATIVE COOL-

ING TOWER UNLESS THE FILLING WATER HARD -

NESS IS CONTROLLED.

S The water pressure must be 2 --- 10 bar (if this is not so,

contact the Technical Support Department).

Loading...

Loading...