12

English

Liebert HPM --- A/W/F/D/H

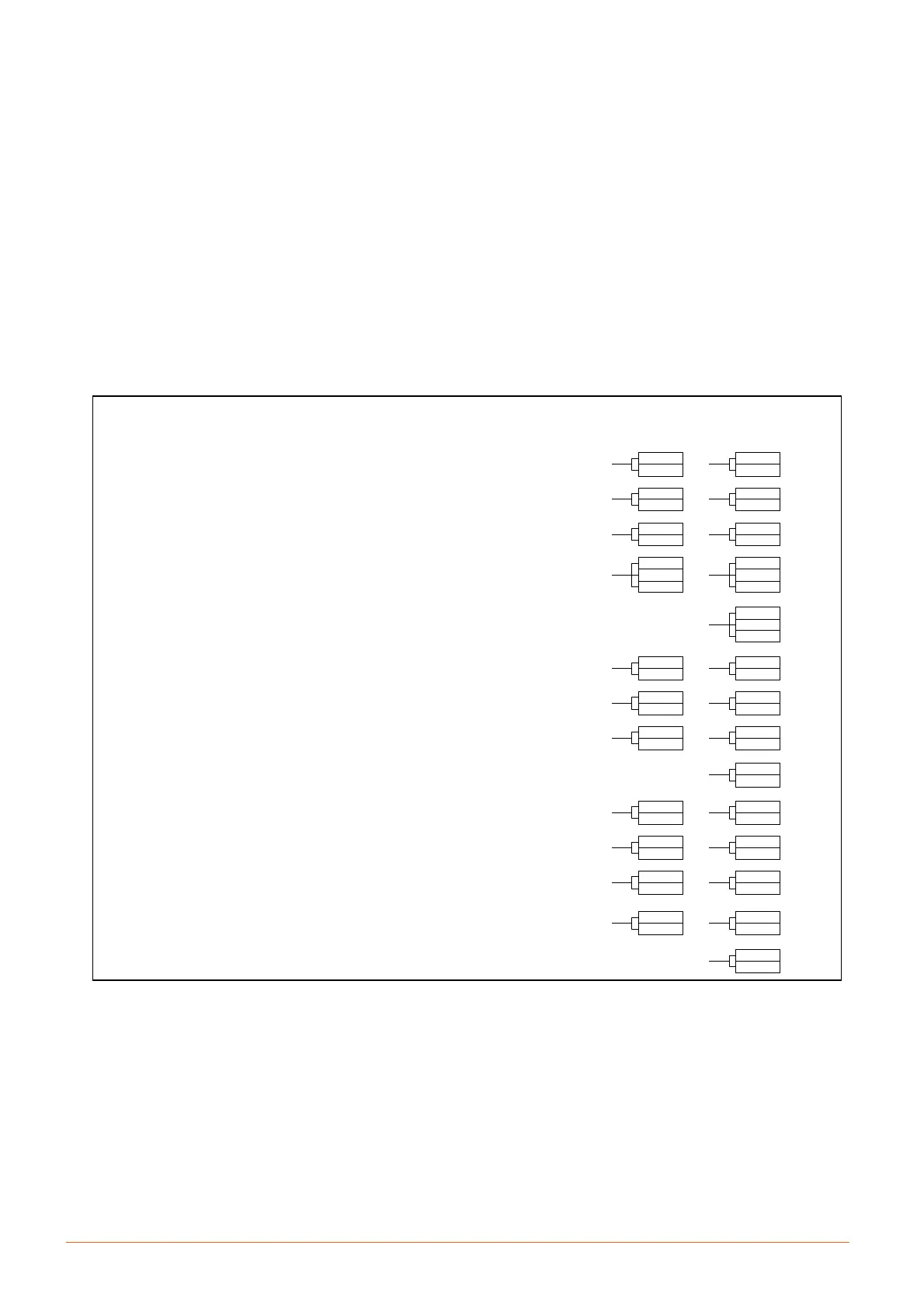

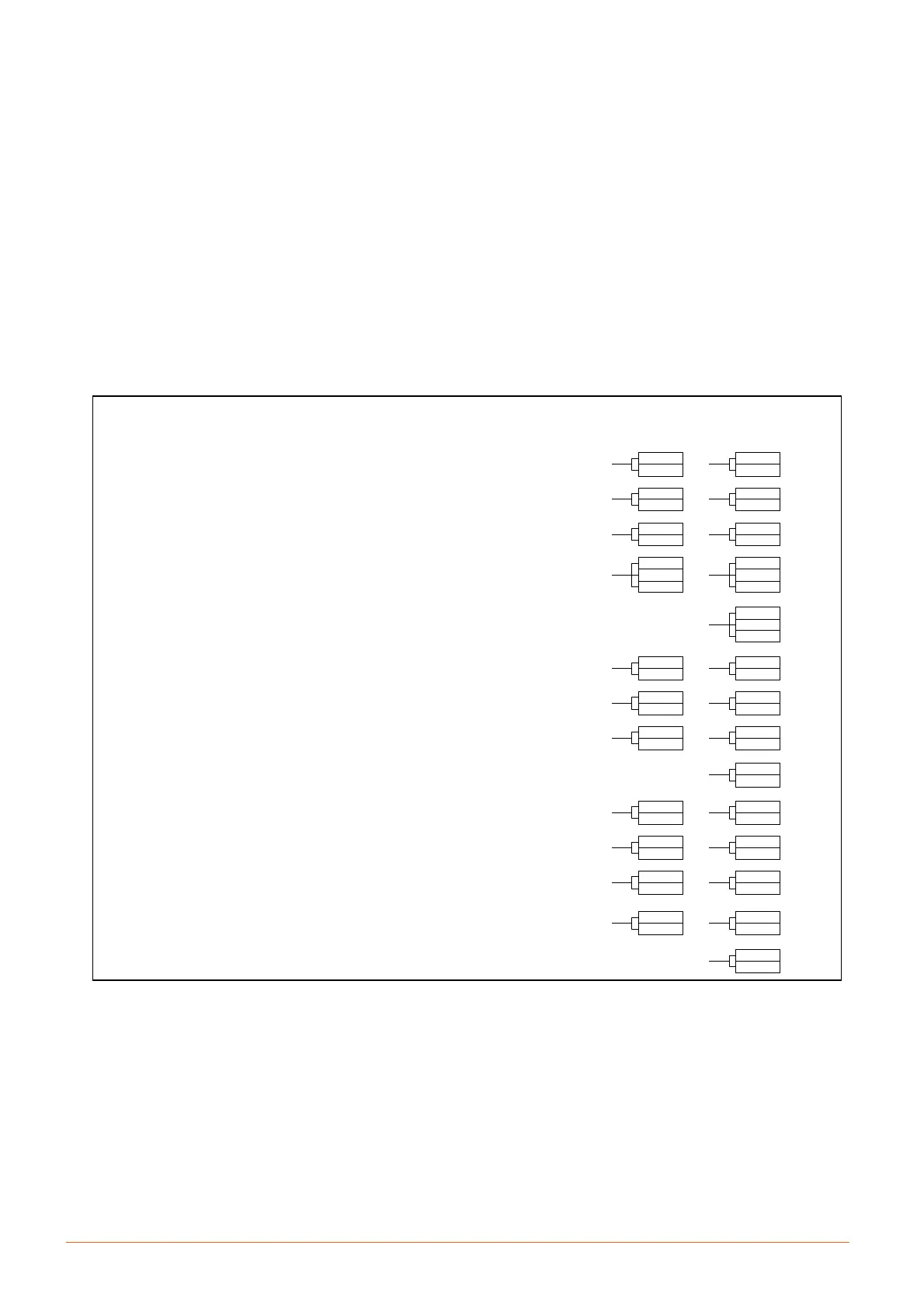

6 --- Electrical connections

6.1

-- Electrical connections

1) Before proceeding with the electrical connections, en-

sure that:

S all electri cal components are undamaged;

S allterminalscrewsaretight;

S the supply voltage and frequency are as indicated on

the unit.

2) Power supply cable connections:

S Connect the cable to the Line inlet terminal board.

S Usethecablesizedefinedaccordingtotheflow,the

supply voltage and the installation type.

S Thesystem/linecableprotectionistobearrangedby

the customer. Use a protection with differential

switch. If the system is equipped with EC fans, use

aBtypeswitch.

S Do not fit the supply cable in the raceways inside the

machine electric board.

S Use multipolar cables with sheath (CEI20 ---22) only.

3) Wiring connec tions (Fig. f):

S Connections for remote on---off and hot water con-

sent must be done by the installer.

S According with compressor running, two terminals

for the opening of a water solenoid valve are avail-

able, by installer (W/H units).

S The General Alarm terminals allow remote alarm sig-

nalling.

4) In case of short circuit, check the sticking of the involved

switch and possibly replace it.

See electrical data in Enclosures B: Technical data

tables.

Fig. f --- Electrical connections

clogged filter (CF)

(CLOSE = OK)

remote on ---off

(CLOSE = ON)

smokestat firestat (AAP)

optional (CLOSE = ON)

water leakage (LWD)

GENERAL ALRM

(400, 401 NC = alarm or unit off)

operating fan

(CLOSE = ON)

operating compressor

(CLOSE = ON)

user alarm

(CLOSE = OK)

freecooling relay enabling, F/D/H only

(CLOSE = ON)

chilled water thermostat enabling,

D version only (CLOSE = compressor ON)

water solenoid valve enabling (by installer) before compressor

i n t e r v e n t i o n , W / H u n i t --- 2 4 V a c --- 1 A m a x

operating compressor 2

(CLOSE = ON)

water solenoid valve enabling (by installer) before compressor 2

i n t e r v e n t i o n , W / H u n i t --- 2 4 V a c --- 1 A m a x

WARNING

(300, 301 NC = warning or unit off)

only on units with EC fan

53

52

61

63

105

106

53

51

400 (NC)

401 (C)

402 (NO)

70

71

72

73

61

62

580

369

83

84

AUXILIARY TERMINAL BOX

(Cooling + Electr. heating + Humidification)

22

0

1 compressor 2 compressors

020

366

1

33

105

106

86

84

400 (NC)

401 (C)

402 (NO)

70

71

72

73

86

030

580

369

710

720

351

355

300 (NC)

301 (C)

302 (NC)

76

77

353

354

6.2 -- Fan connections

The fan is electrically feeded by 1 or 2 autotransformers that

are connected in order to obtain the nominal air flow and the

External Static Pressure (ESP: 20 Pa for Under and 50 Pa for

Over).

To change the factory connection proceed as follow:

--- identify the unit’s aeraulic graph in the Product Docu-

mentation;

--- choose the curve’s point where both the air flow and the

static pressure are the most suitable for the installation;

--- check the factory fan blocks connection and correct it, if

necessary (see electrical diagram);

--- choose the new output fan connections and connect the

wires to the relevant blocks.

6.3 -- Protection degree IP2x check

After whole of t he connect ions and insta llatio n wo rks, com-

prising ceiling elements (plenum, ducting) and floor ele-

ments (base frame), check and verify the protection degree

IP2x (protection against finger access, std. IEC 60364---1) at

the boundary of the air conditioner.

6.4 -- Protective features of EC fan

The

EC fan has been provided with the following protective

features:

S Over temperature of electronics

S Over temperature of motor

S Locked rotor protection

Loading...

Loading...