14

English

Liebert HPM --- A/W/F/D/H

7.4 -- Checking the refrigeration piping pres-

sure drops

Liebert HPM is equipped with connections to check the refri-

geration piping pressure drops:

room unit → condenser → room unit

To carry out this operation it is necessary to use 2 calibrated

manometers and connect them as follows:

M1, connected to the compressor delivery valve;

M2, connected to theSchrader valve (2) of Fig. h.

When the compressor is ruuning, check M1 and M2.

N.B.: Repeat this test , inverting the manometers : tocalcula-

te the correct Δp consider the average value of the two

readings.

Refrigeration pipeline Pressure drops (Δp bar), at 45_C:

S At the same geodetic level: Δp ( b a r ) = M 1 --- M 2

S When condenser is above the room unit:

Δp (bar) = M1---M2+geodetic difference (m x 1,1:10,2)

S When condenser is below the room unit:

Δp (bar) = M1---M2 ---geodetic difference (m x 1,1:10,2)

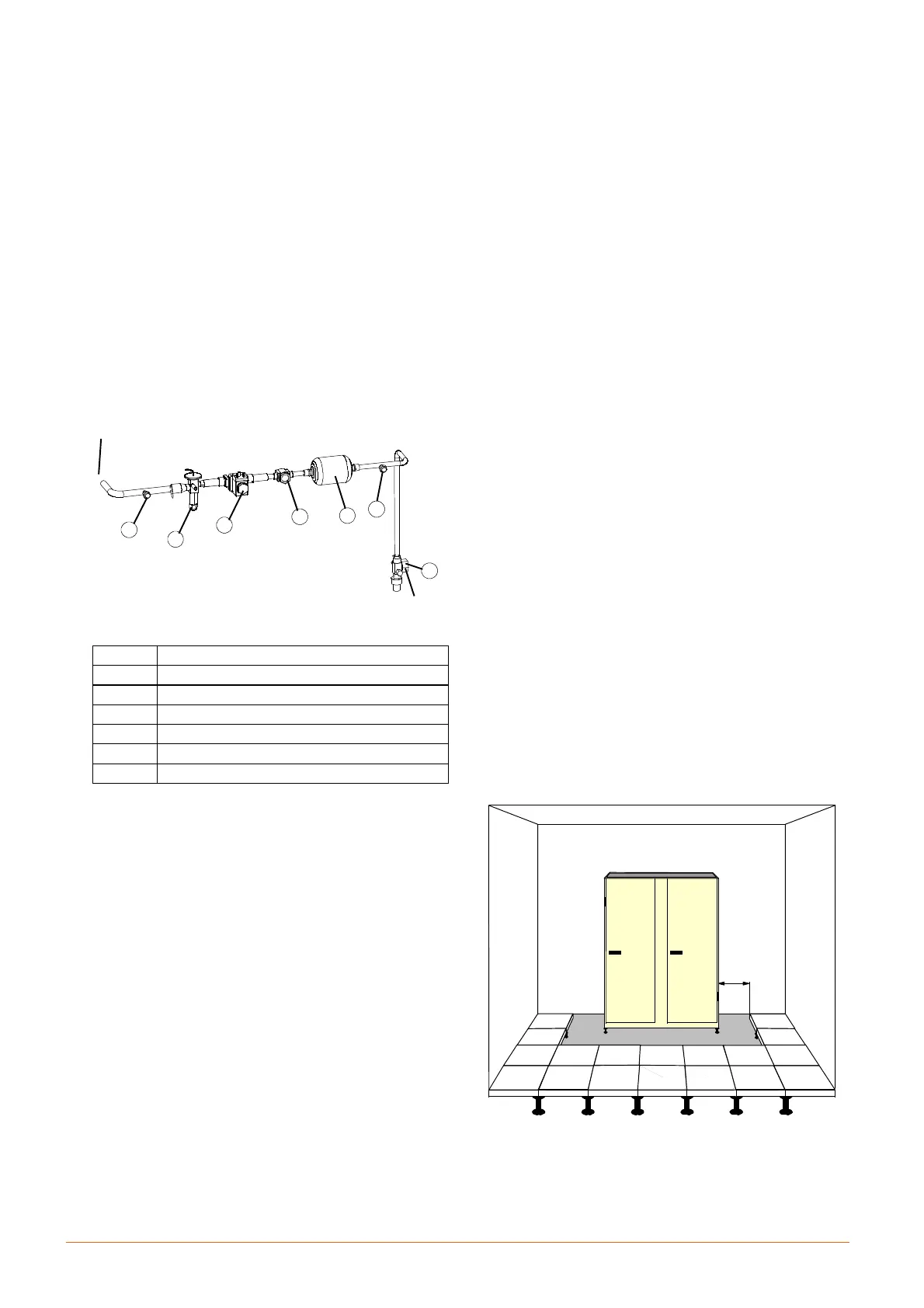

Fig. h --- Refrigerant line components

7

6

5

4

3

2

1

connection

on the Liquid

Receiver

to the

evaporator

1 Liquid receiver valve

2 Filter dryer inlet Schrader valve

3 Filter dryer

4 Sight glass

5 Solenoid valve

6 Thermostatic expansion valve

7 Evaporator inlet Schrader valve

8 --- Operation

Unitoperation iscompletely automatic.The below sequence

explainshowtheunitoperates:

S The air, sucked in by the fan(s), enters the unit.

S The air is immediately filtered.

S The TEMPERATURE sensor or HUMITEMP (temperature

+ rel. humidity) sensor (check type installed), verifies the

state of the inlet air, and relays this information to the control

system.

S Filtered new air is injected into the air stream via the

Fresh Air Intake (optional).

S The treated air passes through the fans, which operate

continuously, and is then dispersed out of the unit.

S Under unit only: the air passe s from the underfloor void

into the room via air distribution outlets.

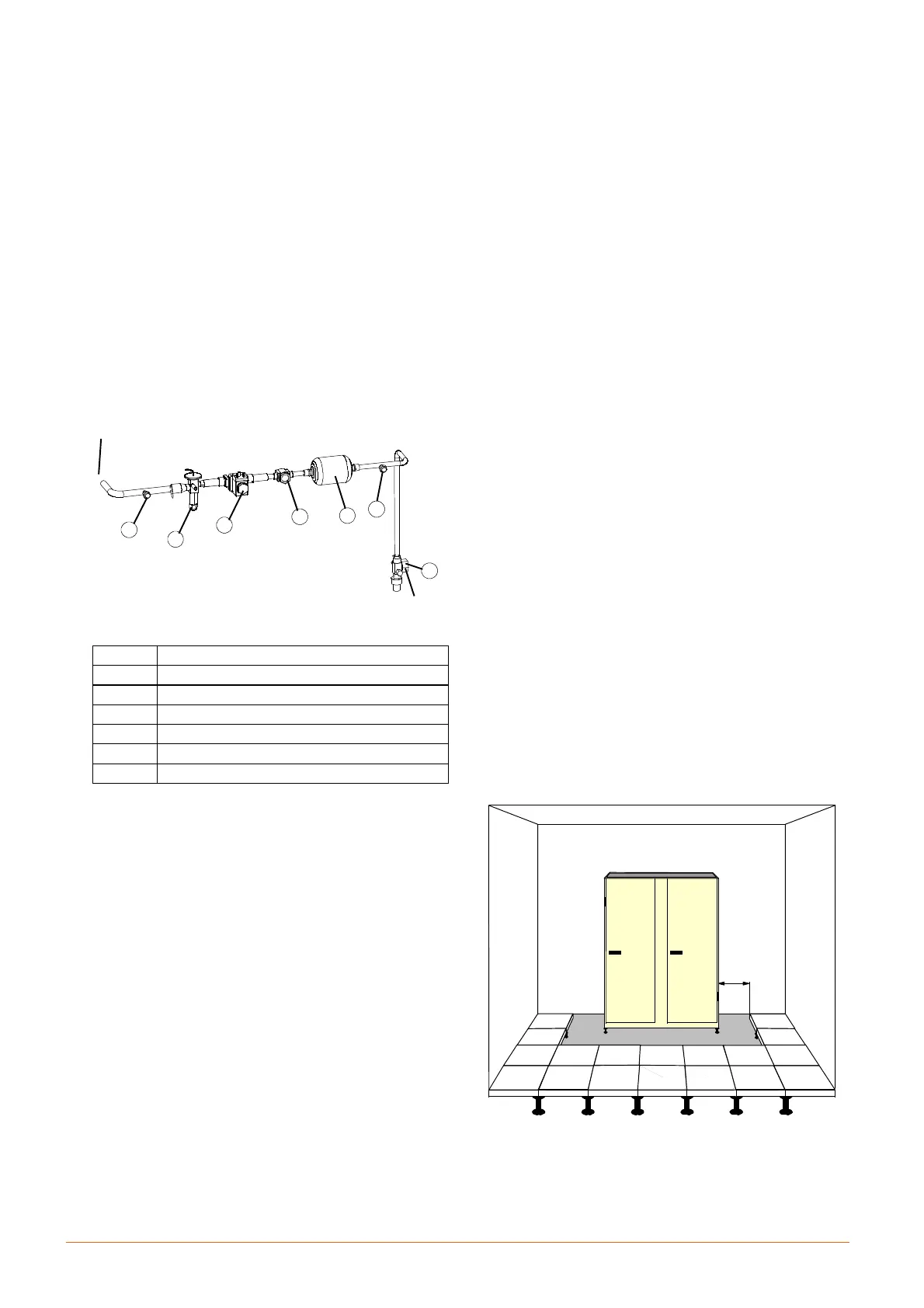

For ”UNDER” units installed on raised floor: switch

off the machine before removal of the floor panels

within a distance of 850 mm from the machine, to

avoid risks of contact with rotating devices (fans)

moving and with hot heating elements. (see Fig. i).

S The control system compares the relayed information to

the set point and proportional band values programmed

into its memory: it then commands the air conditioner to

treat the air as follows (see also Control manual):

S

COOLING

Direct expansion mode (DX)

The compressor is started and the cold refrigerant flows

through the evaporator, thus cooling the air passing over

it. For compressor operation see Control manual.

S

HEATING

Thiscan takeoneof threeforms:

--- electrical heating (optional): the heating elements

heat the air passing over them. There are 3 heating

steps.

--- hot water heating (optional):ifhotwaterisavailable,

this flows through the hot water coil, thus heating the

air passing over it. The hot water flow is contr olled by

a n o n --- o f f ( 3 --- w a y ) v a l v e .

--- hot gas reheat (optional used during dehumidifica-

tion): the hot refrigerant which exits the compressor

flows through the hot gas coil, thus heating the air

passing over it.

S DEHUMIDIFICATION --- optional

DX mode

One of the compres sors starts and either the air flow or

the evaporator surface is reduced (depending on the

model), thereby causing dehumidification (refer also to

Control manual).

In freecooling mode: see Control manual.

N.B.: If, during dehumidification, the ambient temperat-

ure drops below a specified level, dehumidification will

be stopped if necessary (see LOW LIMIT intervention in

Control manual).

S HUMIDIFICATION --- optional

The humidifier creates steam, which is distributed into

the air stream via the steam distribution pipe (see also

Enclosure A).

N.B.: Manual control can beperformed usingthe controlsys-

tem (see Control manual).

Fig. i --- Floor panels removal on a safety way

850 mm

Loading...

Loading...