16

English

Liebert HPM --- A/W/F/D/H

9.4 -- Water condenser flow control valve

(F only)

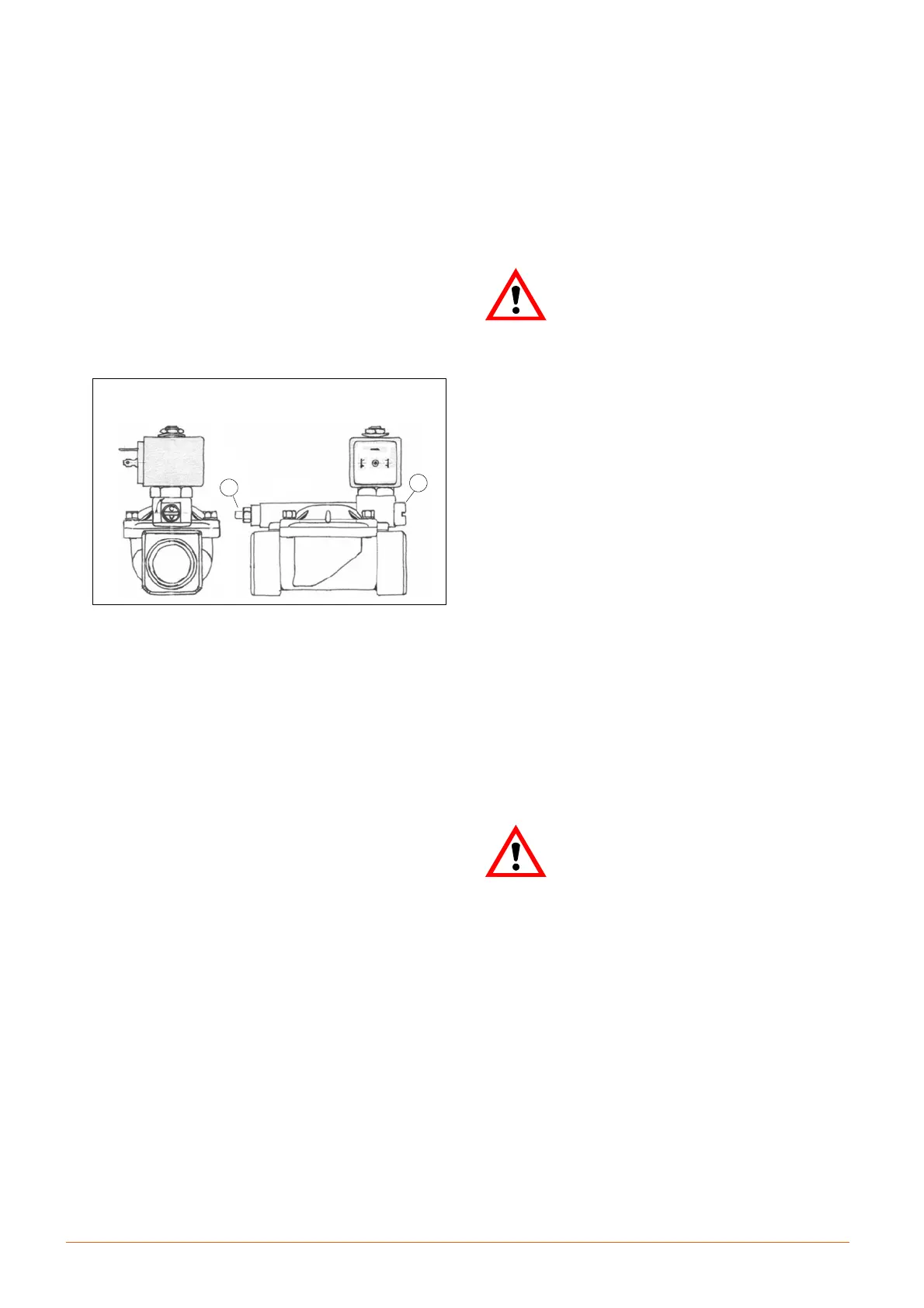

S o l e n o i d 2 --- w a y --- F i g . K s h o w n --- v a l v e , c o n t r o l s t h e p l a t e

condenser water---flow. This valve is equipped with a hand

driven opening system, and a closing---speed control.

Opening hand drive can be used when a main control failure

occurs, and is made by a cylindrical headed screw (screw 1)

which has two position:

Closed --- (valve closed) if letter ”C” is turned upside;

Open --- (valve open) if letter ”A” is turned upside.

When from the ”Closed” position the screw is turned to the

”Open” position (no matter if in clockwise or counterclock-

wise direction) the valve is completely opened. In order to

close the valve again it’s necessary to turn again the screw to

the ”Closed” position. When the hand drive is in ”Closed”

position the valve can open if the coil is energized. Is then

possible to modify the closing times turning a setting screw

(screw 2); the adjustment possibilities range from fully open

position with maximum closing speed to fully closed posi-

tion with valve always open.

Fig. k --- Regulation of water condenser flow control

valve

2

1

9.5 -- Water leakage sensor (Liquistat)

Due to high flooding alarm device sensitivity, to the end to

avoid undesirable alarm signal because of few sporadic wa-

ter drops, place the sensors at a minimum distance of 50 cm

from the unit base perimeter.

This solution assures alarm intervention for real flooding risk

only.

9.6 -- Environment protection

A misuse or an incorrect calibration of the unit leads to in-

creased energy consumption, resulting in an economic and

environmental damage. Use the freecooling function, if

available.

10 --- Maintenance/Spare Parts

10.1

-- Safety instructions

All maintenance operations must be carried out strictly ob-

serving the European and National accident prevention reg-

ulations. We refer especially to the accident prevention regu-

lations concerning electrical systems, refrigerators, and

manufacturing resources.

Maintenance may be done to air conditioning equipment

only by authorized and qualified technicians.

To keep all warrantees valid the maintenance must adhereto

the manufacturer’s regulations.

The work should be done in the system only

when it is at standstill. Do this by switching off

the air conditioner at the controller and the

main switch. Post a warning sign saying: ”DO

NOT SWITCH ON.”

Electrical components o f device have to be switched off

and be checked that they are not under voltage.

Ignoring the safety instructions can be dangerous to per-

sons as well as t o the environment.

Soiled parts always cause a loss of performance and for

switch or control devices can lead to t he break---down of a

plant.

10.2 -- Spare parts

Only original spare parts made by Vertiv may be used.

Using third---party material can invalidate the warrantee.

When making inquiries always refer to the ”Com-ponent

List” supplied with the equipment and specify the model

number, serial number and, if available, the part num-ber as

well.

NOTES:

1) When a faulty component is replaced, follow the relevant

manufacturer instructions.

2) When the spare parts must be welded, be carefully do

not damage the internal parts (gaskets, seals, o ---rings,

etc.).

10.3 -- Maintenance schedule

Monthly, quarterly, biannual and annual checks to be con-

ducted according to the follo wing guidelines.

All tasks and periods listed here are regulations from the

manufacturer and need to be doc umented in an inspection

report.

All these ta sks should be carried out only by

an authorized and trained technician. We

re-commend the Vertiv Cus-tomer Service

Loading...

Loading...