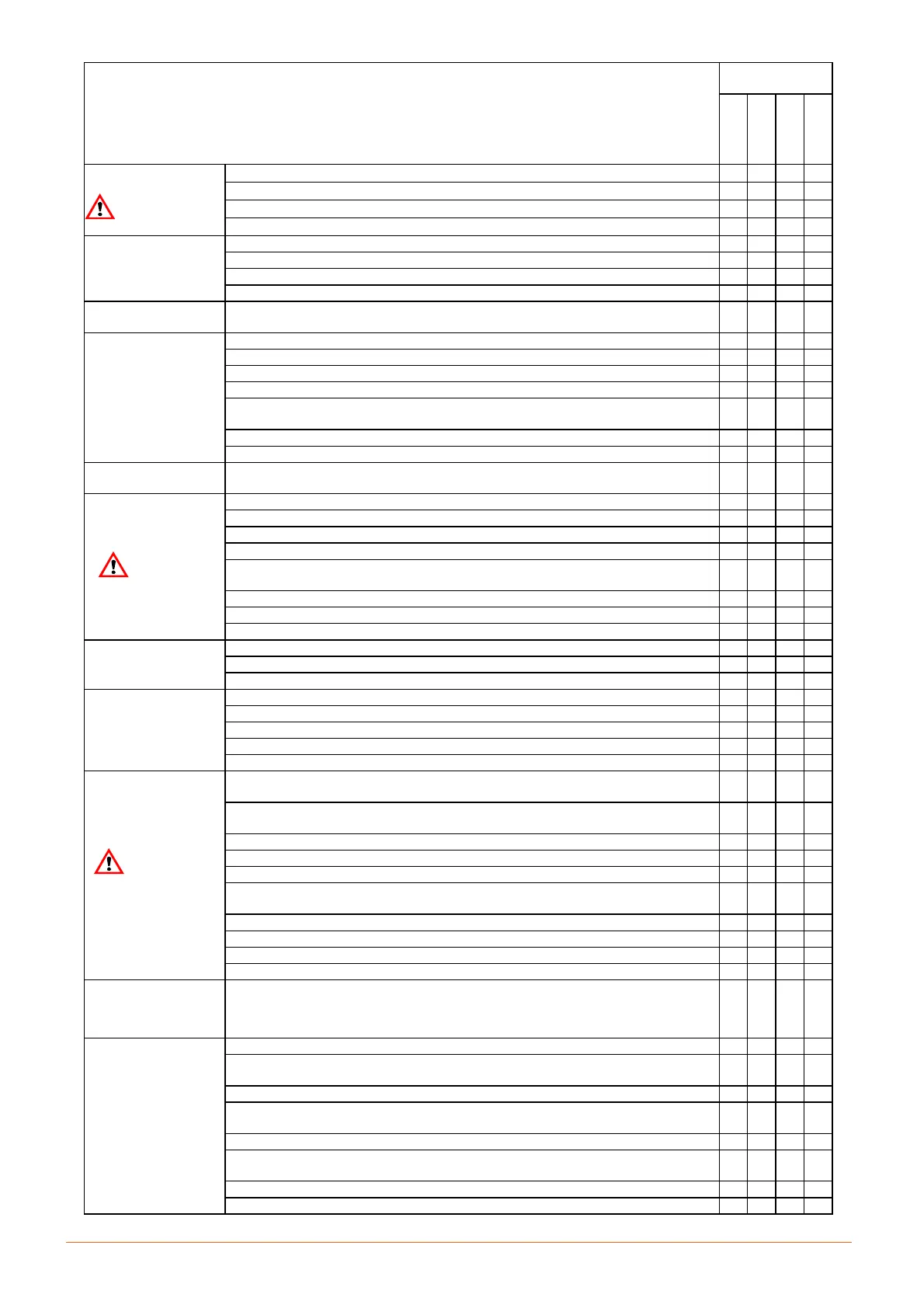

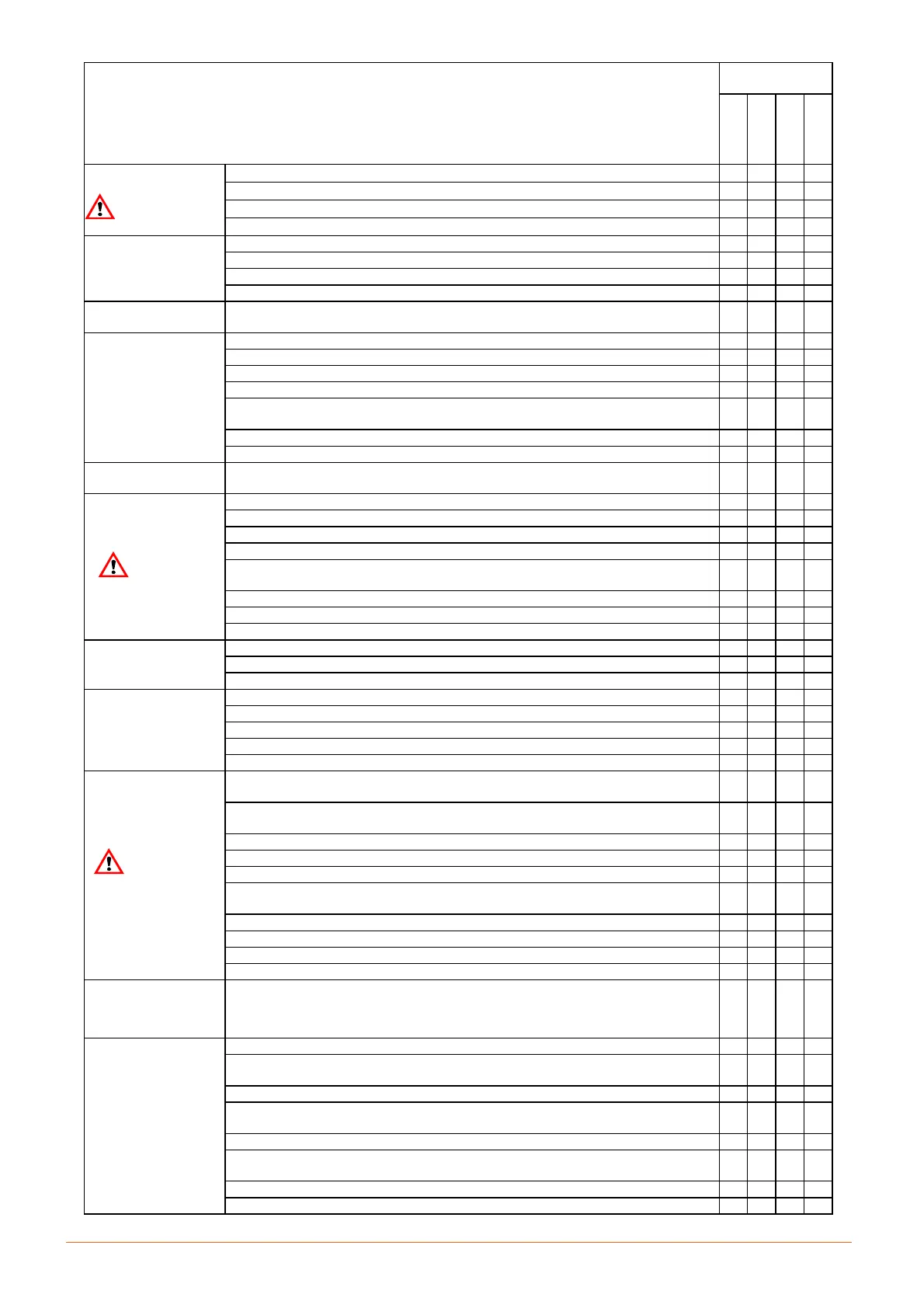

17

English

Liebert HPM --- A/W/F/D/H

Maintenance schedule

COMPONENT

MAINTENANCE

PERIOD EVERY

1Month

3Months

6Months

1Year

FANS

Attention, do not

reach into the fan

while the fan

wheel is running.

Check for soiling, damage, corrosion, and proper fixing. X

Check bearings noise. X

Measure the current and power consumption. X

Cleaning to preserve the function. X

AIR FILTERS

Check for soiling, damage, corrosion. X

Check state of filter. X

Clean or replace if necessary. X

Carry out controls more frequently in dusty environments. X

NEW AIR FILTER

(if installed)

see air filter. Clean or replace X

CONTROL

SYSTEM

Check for proper and functionally correct installation and surrounding conditions. X

Check the function of the LEDs of the display’s control system and the alarms. X

Check the connections for electrical and mechanical function. X

Check the functional elements (e.g. operational controls and display devices). X

Check the electrical/electronic and pneumatic input signals (e.g. sensors, remote

controllers, command variable) for compliance with nominal values.

X

Check control function, control signals, and safety chains. X

Adjust control function and control signals. X

HUMIDIFIER

(if installed)

See appendix A.

SWITCH CABINE T

POWER CIRCUITS

Attention,

electrical

cables and

electrical components

of the air co nditioner

are under voltage.

Check the power supply on all phases. X

Check the connections for electrical and mechanical function. X

Check the power supply at all terminals. X

Measure power consumption at all connected consumers. X

Set, adjust, and tighten the functional elements (e.g. operational controls and display

devices).

X

Check safety equipment, e.g. thermal switch. X

Replace fuses (every 2 --- 3 years) X

Check protective covers for completeness. X

COOLING WATER

(W, F and H only)

Check cooling water circuit. X

Check for damage, leaks, and proper fixing. X

Makesurethereisnolossofwater.

COOLING WATER

(W, F and H only)

Only for closed

circuits:

Make sure that the water pump works properly. X

Deaerate circuits. X

Check whether the heat transfer medium of circuit---connected system is frost--- proof. X

Check safety equipment for function.

Check glycol% comparing minimum yearly ambient temperature. X

Fluoride refri-

gerants in-

crease the green--- house

effect and are subject to

restrictions and norms,

according to the national

and European regula-

tions.

REFRIGERATION

CIRCUIT

Measure the working pressures and temperatures (to be done by a refrigeration

technician).

X

Check the power consumption, measure head temperature, and check for possible

abnormal operating sounds.

X

Make sure that there is no frost building up on the evaporator and compressor. X

Check function of all regulating devices (power regulators, valves, etc.). X

Check safety devices for function. X

If the quantity of refrigerant is not enough, it needs to be reclaimed and refilled with

completely new refrigerant.

Check oil level at the sight glass. X

Carry out a test to ceck humidity inside oil X

Check valves and replace if necessary on industrial piston compressors (every 2 years). X

Check crankcase heater for function. X

EXTERNAL

CONDENSER/

Dry cooler

(if installed)

Seeappropriatemanual.

CHILLED WATER

CIRCUIT

(D and H only)

Makesurethereisnolossofwater. X

Deaerate the cooling water circuit using the vent valve on the top right hand side of the

cooling coil.

X

Check that the cold water supply is ensured. X

Check the temperature and the pressure of the water on the inlet and outlet side using

thermometers and manometers if installed.

X

Check the proper function of the three---way valve. X

Make sure that the system is filled with the prescribed amount of glycol and that there is

no frost in the hydraulic circuit.

X

In case water loss needs to be refilled make sure the glycol concentration is correct. X

Check that the water circulation is in perfect order. X

Loading...

Loading...