3

English

Liebert HPM --- A/W/F/D/H

For A and D units

Outdoor temperature: lower limit

Excee d ing of winter lower limits will temporar il y caus e a comp r es s o r

stop.

down to + 10° C

from +9° C to

--- 2 0 ° C

b e l o w --- 2 1 ° C

standard unit VARIEX required

Consult HPAC Tech-

nical Sales Support

Outdoor temperature: higher limit

This limit is determined by coupl ed condenser model. Exceeding of this

limit (or a lack of maintenance), will caused a compress or stop by HP

safety thermostat. Reset to normal operation can only be carried out

manuall y.

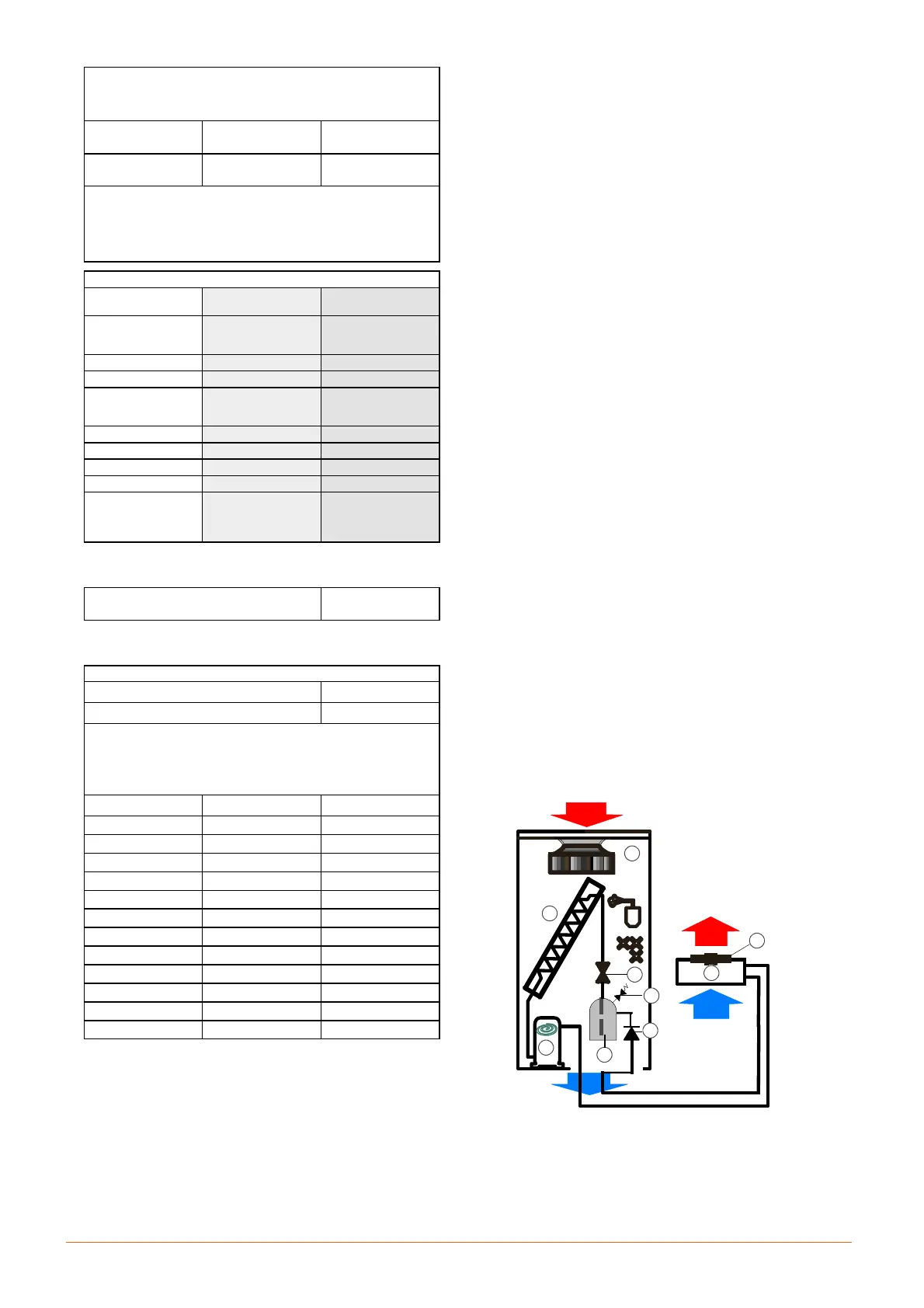

Relative position room unit vs. remote condenser

F r o m unit to cond ens-

er max distance

up to 30 m

equivalent length

from 30 to 50 m

equivalent length

F r o m unit to cond ens-

er max geod etic

heig ht ( 1 ) (2)

from 20 m to --- 3 m from 30 m to ---8 m

Requi r em ents

Pipe diameter see Tab. c see Tab. c

Oil traps on vertical

line of gas refrige-

rant

every 6 m, ma x every 6 m, ma x

Extra oil charge see Tab. 8 see Tab. 8

Variex installation suggested mandatory

Condenser design oversized +15%

Hot gas reheat allowed NOT allowed

Additional non

return valve on deli-

very lin e, at 2 m

from compressor

not

necessary

mandatory

For W, F and H units

Water or mixture temperature to condenser,

lower limit (other information par. 5.4)

min. 5° C

For F, D and H units

Chilled water circuit

inlet water t emperature min. 5°C

water pressure max. 16 bar

Max. differential pressure s on th e modulating valve

(2 or 3 ways)

--- Max. differential pressure through the closed valve: Δp

cv

--- Max. differential pressure across the valve for modulating service:

Δp

ms

Model s

Δp

cv

(kPa) Δp

ms

(kPa)

S1GxF/D/H 300 300

S2ExF/D/H 300 300

S2GxF/D/H 300 300

M2HxF/D/H 300 300

M3FxF/D/H 175 175

M3GxF/D/H 175 175

M4ExF/D/H 175 175

M4HxF/D/H 175 175

M5BxF/D/H 175 175

M5CxF/D/H 175 175

M5DxF/D/H 175 175

L8Fx F/D/H 150 200

(1) Positive difference in height: condenser above conditioner

(2) Negative difference in height: condenser below conditioner

Other information in para 5.3.

1.12 -- Noise level limits

The sound pressure level in free field at 1.5 m height and 2 m

in front of the air conditioner , with compressor and fan in op-

erations, is less than 70 dBA for all models.

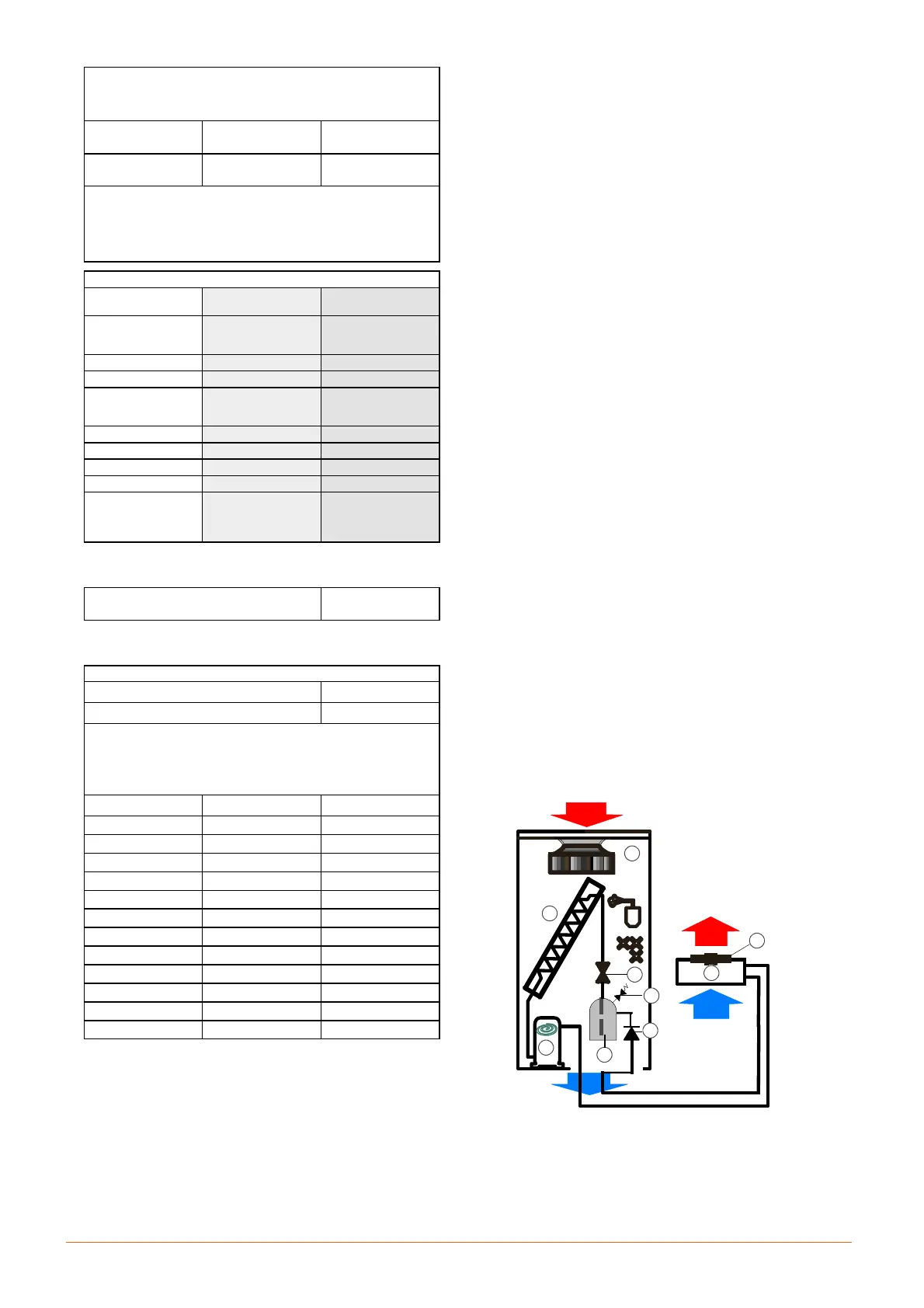

2 --- General description

2.1 --

Direct expansion units

2.1.1 --- Refrigeration circuit

All models are provided with a single refrigeration circuit, M

and L ranges present also double circuit units. The com-

pressor (1) pumps the hot gaseous refrigerant into an o ut-

door air---coo led condenser (2). The liquefied refrigerant ar-

rives to a liquid receiver (3) that ensures a constant and even

refrigerant flow to the thermostatic expansion valve (4) and

then arrives to the evaporator (5). Here the refrigerant,

thanks to the heat --- exchanged with the room air moved by

the fan (6) --- evaporates and returns to the compressor (1);

from this, the refrigerant begins a new refrigeration cycle. To

maintain the correct refrigerant discharge pressure, the

speed of th e m otor f an (8 ) is con trolled (on---of f or propor-

tional mode).

Shut---off valves are provided as standard to assist wit h

routine maintenance.

The compressor (1) has abuilt---in non---returnvalve toavoid

return of liquid ref rigerant from the conden ser in summer-

time, thus protecting the compressor from undesired refri-

gerant slugging during the start up. A second non---return

valve (7) is recommended to avoid --- in wintertime --- refri-

gerant migration from the liquid pipes and the receiver (3) to

the cond en ser (2), th at sh ould b e resp on sib le of low pres-

sure intervention at the start---up of compressor.

For safety reason, a relief valve (9) is installed on the liquid

receiver (3); this valve is equipped with flanged connections

so that the refrigerant may be discharged to the outside.

2.1.2 --- Version A

External air---cooled condenser (2)

The units may be connected with a w id e range of our con-

densers in standar d or low noise versio n. For technical data

and performance, refer to the relevant technical documenta-

tion.

Note 1. Units and exter nal condensers are supplied separ-

ately.

Note 2. The room unit refrigeration circuit is pressurised

with helium at 3 bar and the condenserrefrigeration circuit at

2bar with dry air.

Note 3. The customer is resp onsible for making connec-

ti ons bet ween the Uni t and th e externa l c ondenser a nd for

charging with refrigerant (standard R410A) and oil, when re-

quest.

SxxUA

MxxUA

LxxUA

Units

1

2

4

8

5

6

3

9

7

2.1.3 --- Version W

Wate

r---cooled condenser

These units are provided with one very efficient stainless

steel brazed---plate water---cooled condenser (2). The co n-

Loading...

Loading...