4

English

Liebert HPM --- A/W/F/D/H

denser is fitted with an head--- pressure regulating valve (8)

for the automatic control of condensing pressure.

The units operate with mains water or closed circuit with

an external Dry Cooler. When operating in a closed circuit,

to avoid undesired ice formation in wintertime, it is advisable

to use water/glycol mixture: refer to Chap. 5 for the percent-

ages to be used at minimum ambient temperatures. Dry

Coolers are available as an option; water ---glycol mixture

and circulation pump(s) are normally supplied by others.

If mains water is used, a mechanical filter must be fitted in the

water circuit to protect the plate condenser (2) (for other in-

formation see the Service Manual).

To reduce water and energy consumption (pump), it’s advis-

able to adopt a cooling water control valve (by the user), able

to stop water feeding when unit is off.

Unit microprocessor control gives a 24V contact (10VA max,

please refer to the relevant Wiring Diagram, 58 and G termin-

als) to drive that valve.

Note. The water ---cooled Liebert HPM versions are filled

with the complete charge of the requested refrigerant

(standard R410A).

SxxOW

MxxOW

Units

1

2

3

9

4

8

5

6

7

Cooling Water

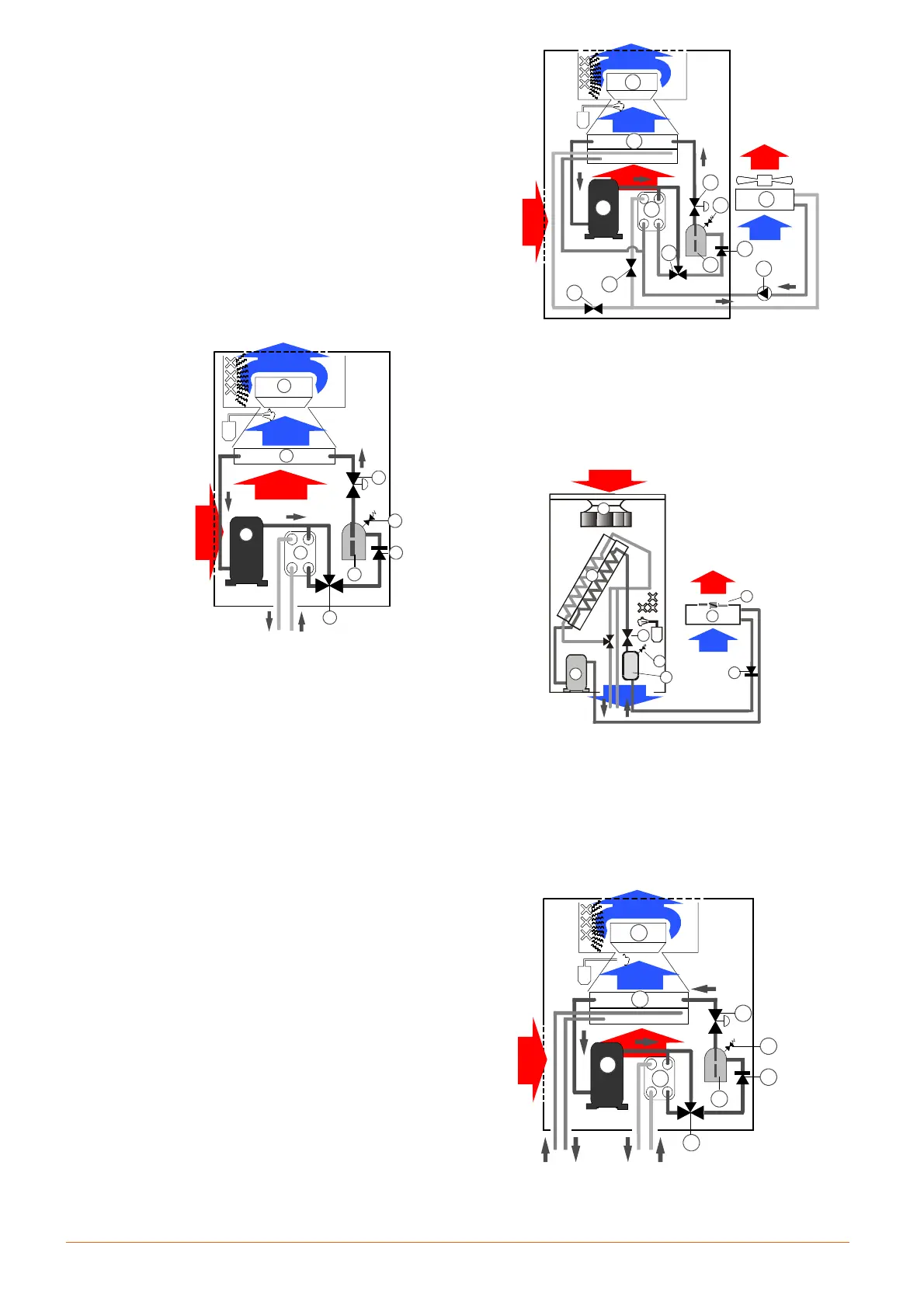

2.1.4 --- Freecooler units --- Version F

Freecooling

mode

The Freecooler unit cools the air flow by means of the air re-

frigerant c o il ( 5) i n di re c t expansi on rows [dir ect expansion

mode] or, as an alternat ive, the air/water coil (5) in freecool-

ing rows [freecooling mode]. Wheneverthe outdoortemper-

ature is at least 5 degrees below the indoor return temperat-

ure, the water flow is cooled by an external Dry Cooler ( 10)

and passes through the coil (5). When the externaltemperat-

ure is higher than ZET (Zero Energy Temperature), the water

exchanges heat with the refrigerant in the water---cooled

plate condenser (2). When the external temperature is below

ZET, the water is cooled as much as to cool the room air dir-

ectly in the air/water coil (5, freecooling rows).

Water/glycol circuit

The units operate with water in closed circuit with an ex-

ternal Dry Cooler (10), cooled by the outside ambient air.To

avoid undesired ice formation in wintertime, it is advisable to

use water/glycol mixture: refer to the Service Manual for the

percentages to be us ed at minimum ambient temperatures.

The circulation of the water---glycol mixture is forced (the

pump (11) and the wat er---gl yco l mixtur e are not supplied).

The unit is provided with 2---way modulating valve (12) to

control the glycoled---water flow passing through the water/

glycol coil. A solenoid valve (13) allows the water flow to the

condenser.

The opening or closing signals , generated by the el e ctronic

cont rolle r, manage the valve actuator movement in order to

maintain the desiderd conditions in the conditioned room.

SxxOF

MxxOF

Units

1

9

4

8

5

6

7

10

11

3

13

2

12

2.1.5 --- Air---cooled condenser dualfluid units

Version D

Dualfluid

modes

The Dualfluid unit cools the air flow by means of the air refri-

gerant coil (5) in direct expansion rows [direct expansion

mode: see refrigeration cir c uit] o r, as an alternative, the air/

water coil (5) in the chilled water rows [chilled water mode].

SxxUD

MxxUD

L8F U D

Units

Chille d Wate r (fro m Cu s t o mer)

8

9

1

5

6

2

7

3

4

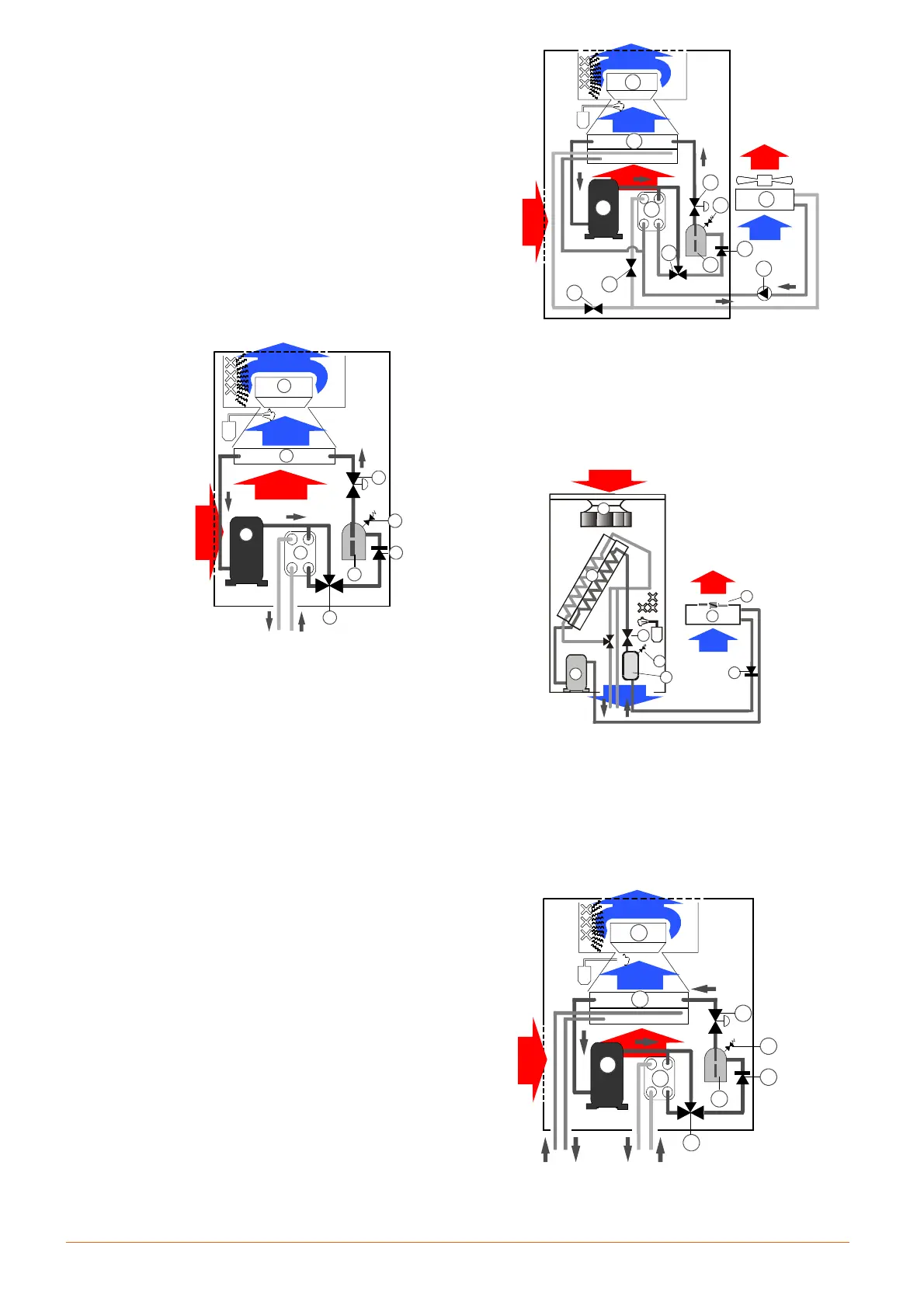

2.1.6 --- Water---cooled condenser dualfluid units

V

ersion H

Dualfluid mode

The Dualfluid unit cools the air flow by means of theair---refri-

gerant coil (5) in direct expansion rows [direct expansion

mode: see refrigeration cir c uit] o r, as an alternative, the air/

water coil (5) in the chilled water rows [chilled water mode].

SxxOH

MxxOH

Units

Co o ling Wat er

Chilled Wat er

(from Customer)

1

2

3

9

4

8

5

6

7

Loading...

Loading...