Vertiv | Liebert LVC | User Manual 14

Installation

1. When the condensers are installed side by side, at least 0.5m engineered mounting bracket

height is required, which can increase the return air area and reduce the wind resistance.

2. When the condensers are installed side by side, the distance between the adjacent condensers

is reserved about 30mm, so the condenser can be lifted out for maintenance.

3. Figure 2-10, when multiple condensers are installed side by side, it is suggested that the width of

1300mm is reserved for every 6 condensers for maintenance.

4. The space requirement of condensers is based on enclosure height less than 1m in

Table 2-1 & 2-2. If enclosure height more than 1m, it is must to increase engineered mounting

bracket height. Please consult Vertiv personnel for technical conrmation.

5. The maximum number of side by side condenser which can be installed is 10.

1.4. Installation Procedures

• Before commencing any copper-pipe welding process, release all Nitrogen charges from the

indoor and outdoor units.

1.4.1. Installing Pipelines

• Protect copper pipes from any surrounding heat sources. Separate the copper pipes from structures

or other obstacles using rigid supports. Avoid dust and water vapor to entered in copper pipes.

• Use a good quality, silver-based solder for all brazed connections. Use refrigeration grade copper pipes

and ttings throughout the installation. Remove all Nitrogen from pipes during brazing to prevent

oxidation.

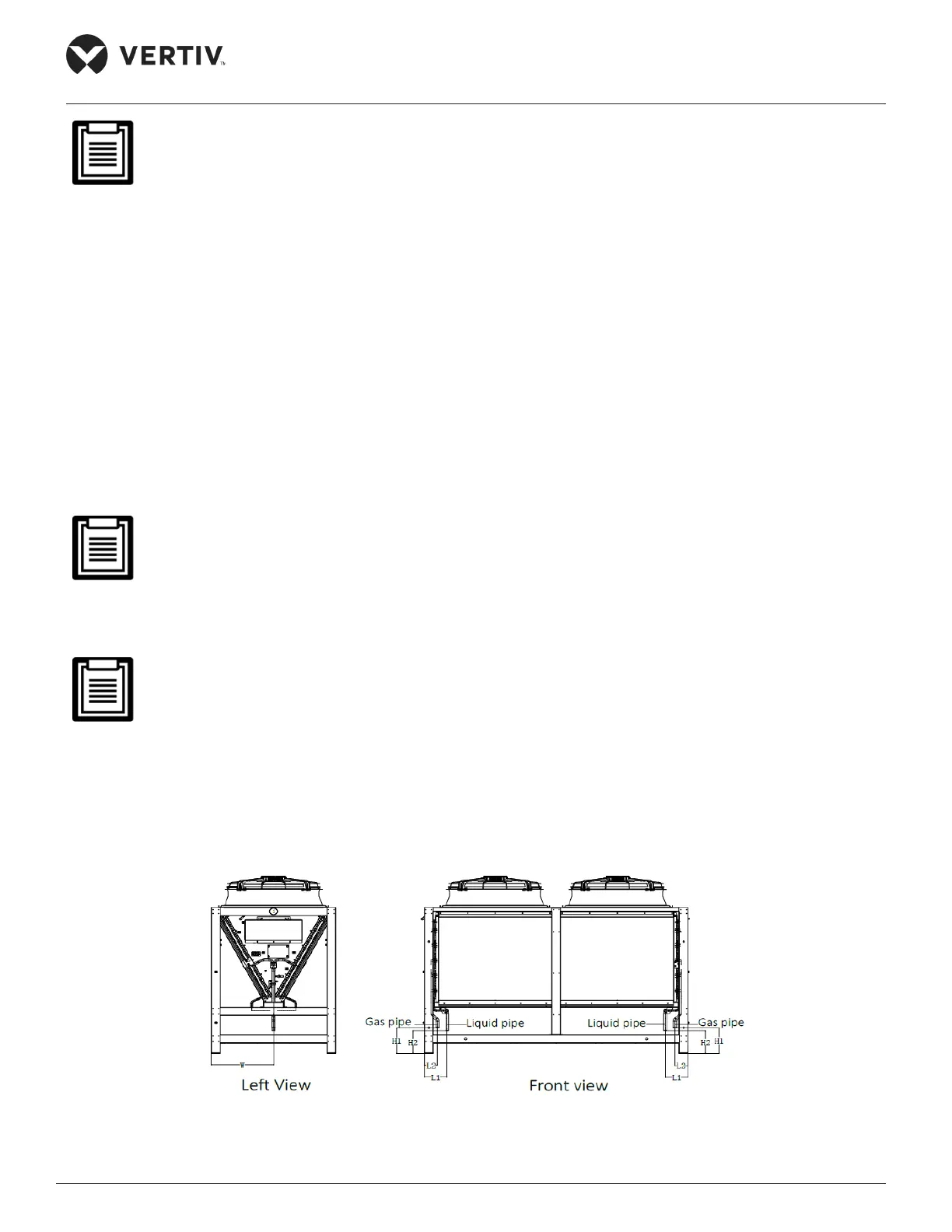

1. Location of gas and liquid pipe: The location of gas and the liquid pipe is shown in Figure 2-11. The

location parameters of each model are listed in Table 2-3.

Figure 1-11 The Position of Gas and Liquid Pipe

Loading...

Loading...