VESDA-E VEA Commissioning Guide

4 32407_01

3 NFPA72 Code Compliance

3.1 NFPA72 Requirements

VESDA-E VEA is classified as an Aspirating Smoke Detection (ASD) product and it complies with NFPA72

Initial Acceptance and Annual testing requirements with minimal testing. With full supervision and automated

centralized tests, VEA verifies end to end system operation continuously and automatically performs system

integrity tests at set times and at much shorter intervals than the annual period required by NFPA72.

The below sections are taken from the NFPA72 2013 edition.

14.2.8 Automated Testing

14.2.8.1 Automated testing arrangements that provide equivalent means of testing devices to those specified

in Table 14.4.3.2 at a frequency at least equivalent to those specified in Table 14.4.3.2 shall be permitted to

be used to comply with the requirements of this chapter.

14.2.8.2 Failure of a device on an automated test shall result in an audible and visual trouble signal.

14.2.9 Performance-Based Inspection and Testing

As an alternate means of compliance, subject to the authority having jurisdiction, components and systems

shall be permitted to be inspected and tested under a performance-based program.

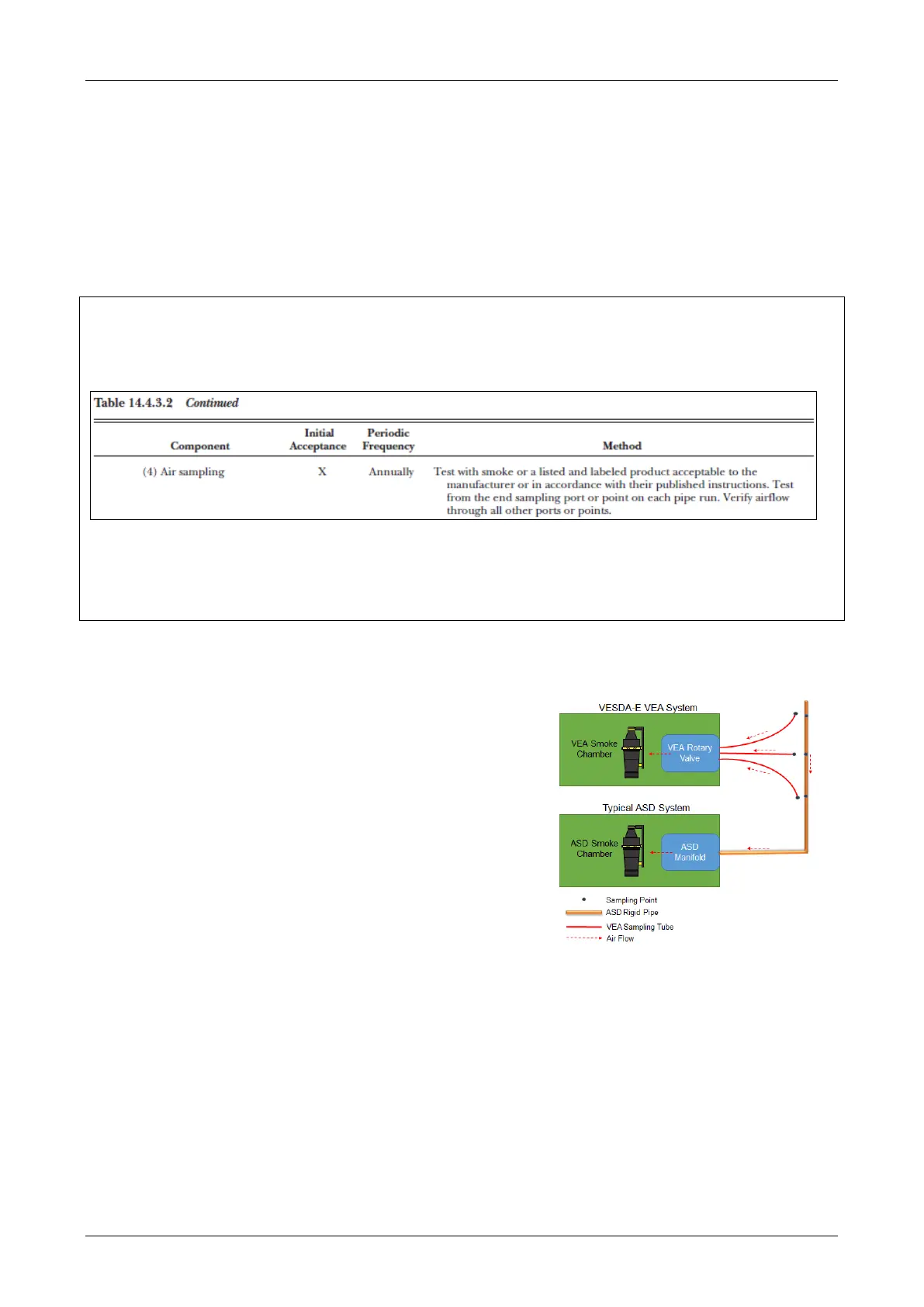

Explanation of VEA being an Air Sampling Detector (ASD):

VESDA-E VEA is an ASD system like any other.

The figure represents the two types of ASD and shows that VEA

is an ASD system that works in the same way as the other ASD

systems:

• ASD using rigid orange pipes: each pipe can have multiple

sampling holes that transfers smoke to a centralized smoke

chamber through a manifold. Hence the sample air entering

the smoke chamber is combined from all the sampling

holes from individual pipes.

• VESDA-E VEA ASD using tubes: an ASD that has a tube

for each sampling hole, smoke is transferred from all these

holes to a centralized smoke chamber through a manifold

in the rotary valve. Hence the sample air entering the

smoke chamber is combined from all the sampling points

connected to individual tubes.

So both ASD systems work exactly in the same way; the same rules apply to both the systems.

In addition:

• VEA continuously monitors airflow from each sampling point to detect clogged/broken tubes or sample

points meeting NFPA72 Table 14.4.3.2 Air Sampling requirement of verification of airflow.

• Full supervision of sampling port and microbore tube at set intervals much shorter than annual

requirement in NFPA72.

• End to end system integrity monitoring allows centralized smoke test (to test smoke chamber) which

Xtralis recommends to test during commissioning and at the time of annual maintenance.

Loading...

Loading...