Series 751 FireLock

®

European Alarm Check Valve Stations

12

MAINTENANCE

The following steps instruct on how to remove and replace inter-

nal valve components. It is important that care be taken to avoid

damage to parts.

Removing and Replacing Clapper Seal for

DN 100 and DN 150 Size Valves

1. Perform steps 1 – 4 of the “Required Internal Inspection”

section, starting on page 10.

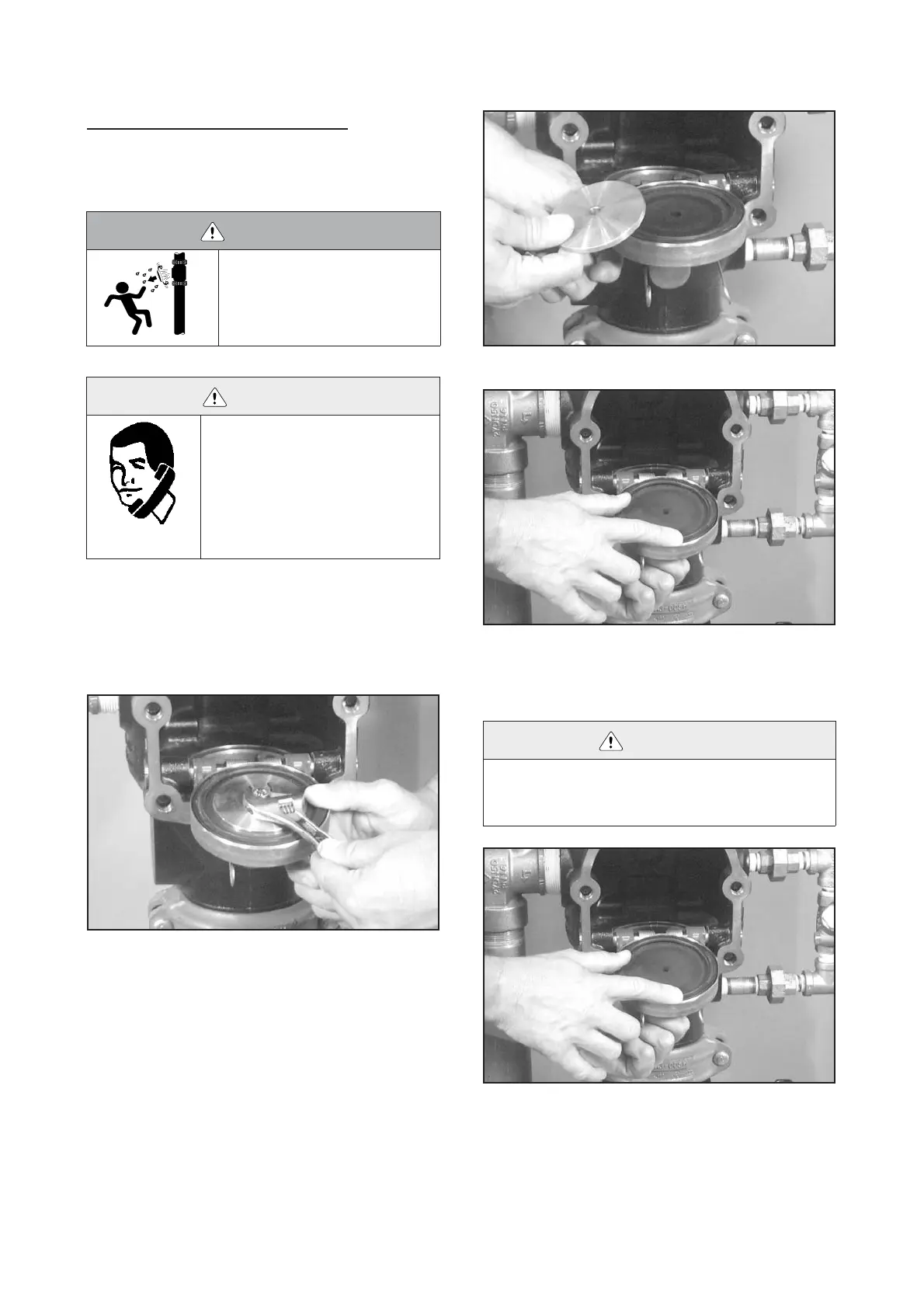

2. Remove the seal assembly bolt/bolt seal from the clapper,

as shown above.

3. Remove the seal-retaining ring. This seal-retaining ring will

need to be re-installed in later steps.

4. Remove the solid seal from the clapper and discard.

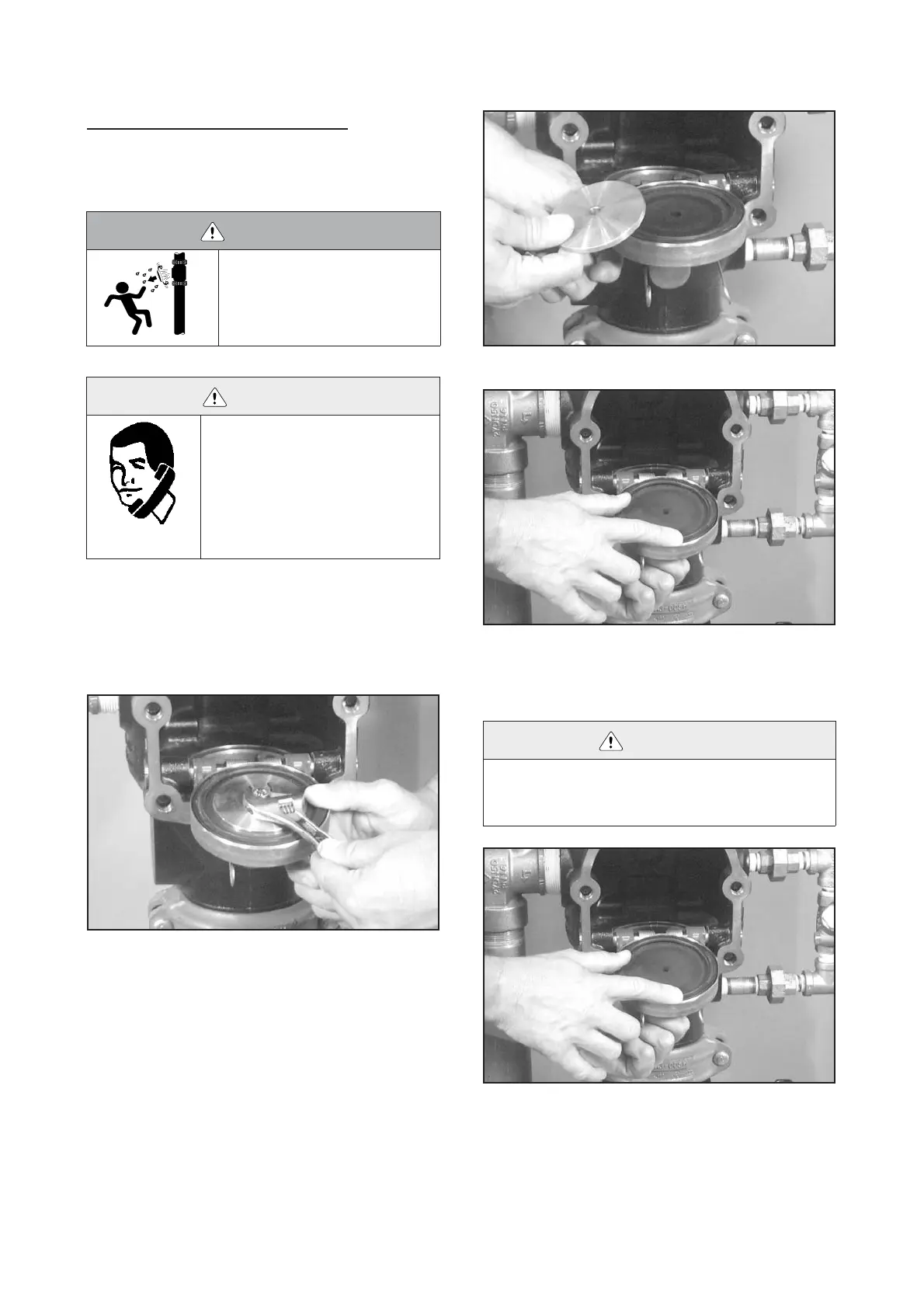

5. Make sure the clapper is free of contaminants, dirt, and

mineral deposits. Clean any holes in the valve body seat ring

that are plugged. DO NOT USE SOLVENTS OR ABRASIVES.

6. Install the new solid seal into the clapper, as shown above.

NOTE: Make sure the sealing lip is pointing upward.

WARNING

• Depressurize and drain the piping system

before attempting to install, remove, or

adjust any Victaulic piping products.

Failure to follow this instruction could cause

serious personal injury and/or property dam-

age.

CAUTION

• Any activities that require taking the valve out of

service may eliminate the fire protection pro-

vided.

• Before servicing or testing the system, notify the

authority having jurisdiction.

• Consideration of a fire patrol should be given in

the affected areas.

Failure to follow these instructions could cause

serious personal injury and/or property damage.

CAUTION

• DO NOT use solvents or abrasives on or near the valve body seat ring.

Failure to follow this instruction could prevent the clapper from sealing prop-

erly, resulting in improper valve operation, valve leakage, and/or property

damage.

Loading...

Loading...