Series 751 FireLock

®

European Alarm Check Valve Stations

5

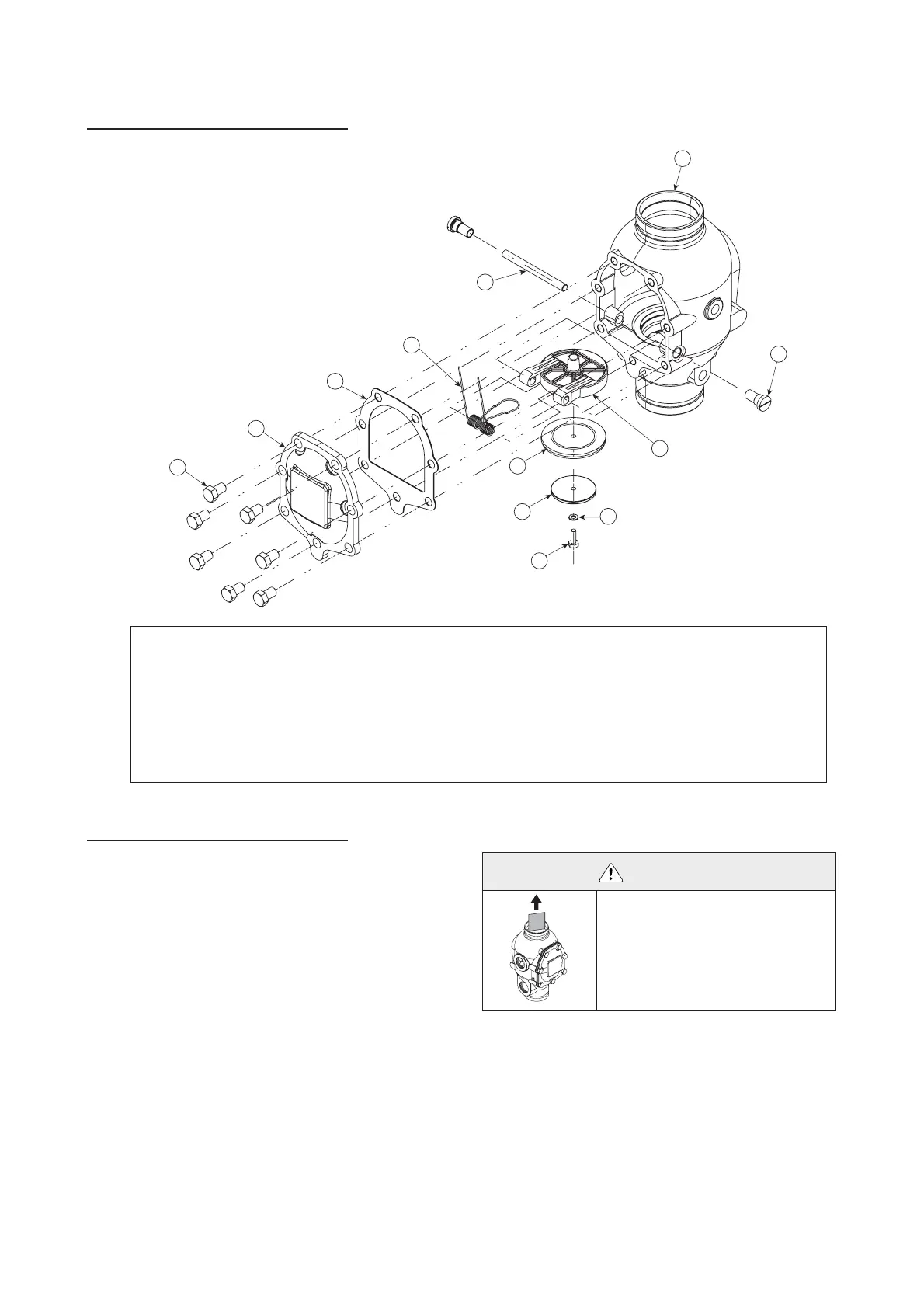

EXPLODED VIEW DRAWING – INTERNAL VALVE COMPONENTS

IMPORTANT INSTALLATION INFORMATION

1.

Before installing the Series 751 Alarm Check Valve, flush

the water supply piping thoroughly to ensure that no foreign ma-

terial is present.

2.

The Series 751 Alarm Check Valve MUST NOT be located

in an area where the valve is subject to freezing temperatures or

physical damage.

3.

It is the owner’s responsibility to confirm material compat-

ibility of the Series 751 Alarm Check Valve, trim, and associated

accessories when a corrosive environment or contaminated wa-

ter is present.

4.

Series 751 Alarm Check Valves MUST be installed in the

vertical position only. The arrow on the body must point upward,

and the arrow on the swing check valve in the bypass line must

point upward.

5.

The Series 752 Retard Chamber should be installed in

variable pressure applications. Victaulic provides specific trim

drawings for installations that involve a Series 752 Retard Cham-

ber.

6.

Confirm that all installation information is available.

7.

Remove all plastic caps and foam spacers from the valve.

8.

Install the Victaulic Series 751 Alarm Check Valve in ac-

cordance with the applicable trim drawings. Make sure the trim

drawing matches the system’s requirements (i.e. retard cham-

ber for variable pressure installations).

BILL OF MATERIALS

1 Valve Body 7 Seal-Retaining Ring

2 Clapper Shaft Retaining Bushing (Qty. 2) 8 Bolt Seal

3 Clapper Shaft 9 Seal Assembly Bolt

4 Clapper 10 Cover Plate Gasket

5 Clapper Spring 11 Cover Plate

6 Clapper Seal 12 Cover Plate Bolts (Qty. 7)

1

12

11

4

3

2

10

6

7

9

5

8

CAUTION

• Make sure foam spacers are removed before

attempting to install the valve.

Failure to follow this instruction could cause

improper valve operation, resulting in serious per-

sonal injury and/or property damage.

Loading...

Loading...