Series 751 FireLock

®

European Alarm Check Valve Stations

10

REQUIRED INTERNAL INSPECTION

The authority having jurisdiction in your area may have estab-

lished requirements for internal inspection frequencies. Verify

these requirements by contacting the authority having jurisdic-

tion in your area.

1. Notify the authority having jurisdiction, remote station

alarm monitors, and those in the affected area that the system is

being taken out of service.

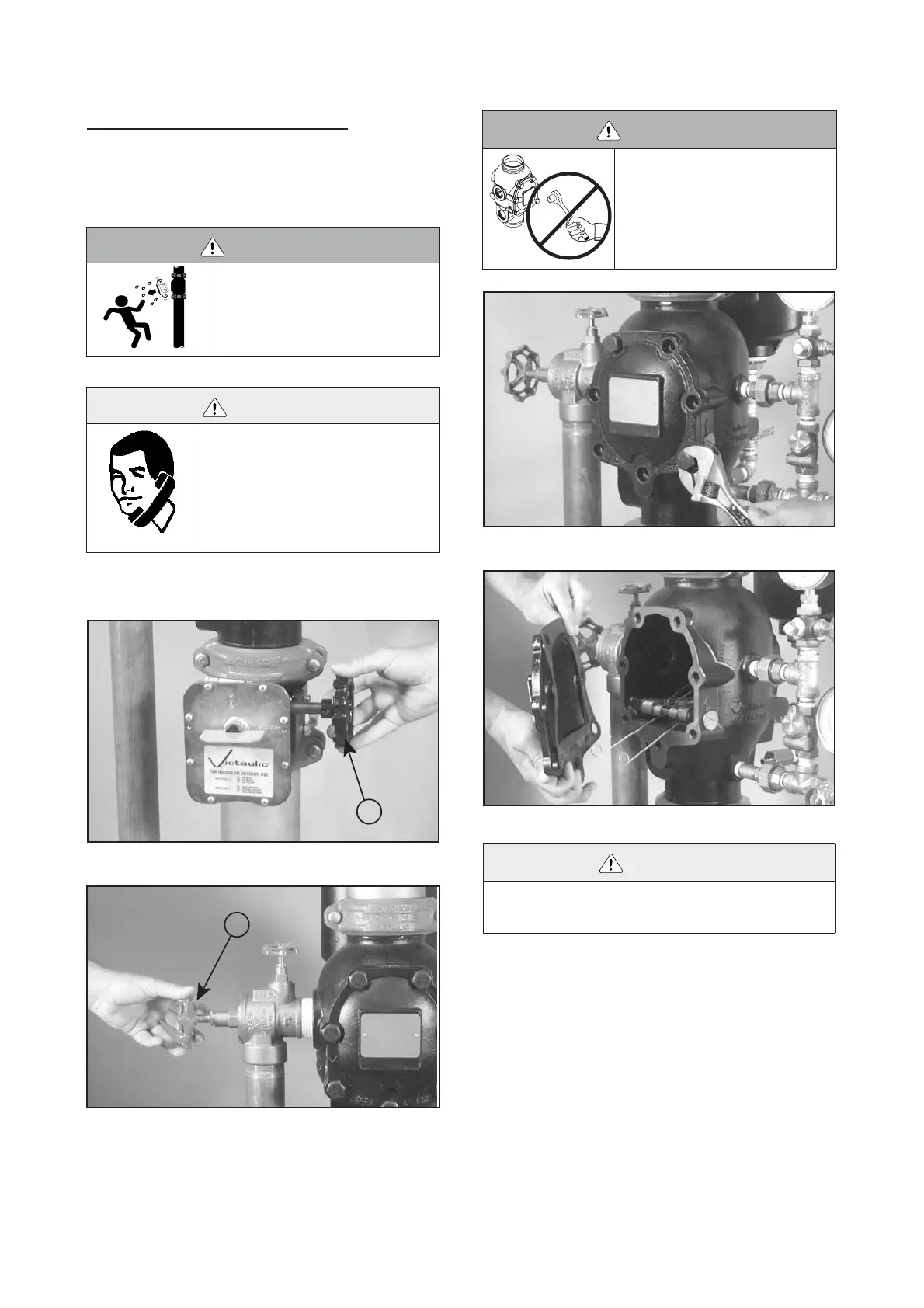

2. Close the water supply’s main control valve (3) to take the

system out of service.

3. Open the system main drain valve (14), and allow the sys-

tem to drain completely. It may be necessary to open the auxil-

iary drains in order to drain the system completely.

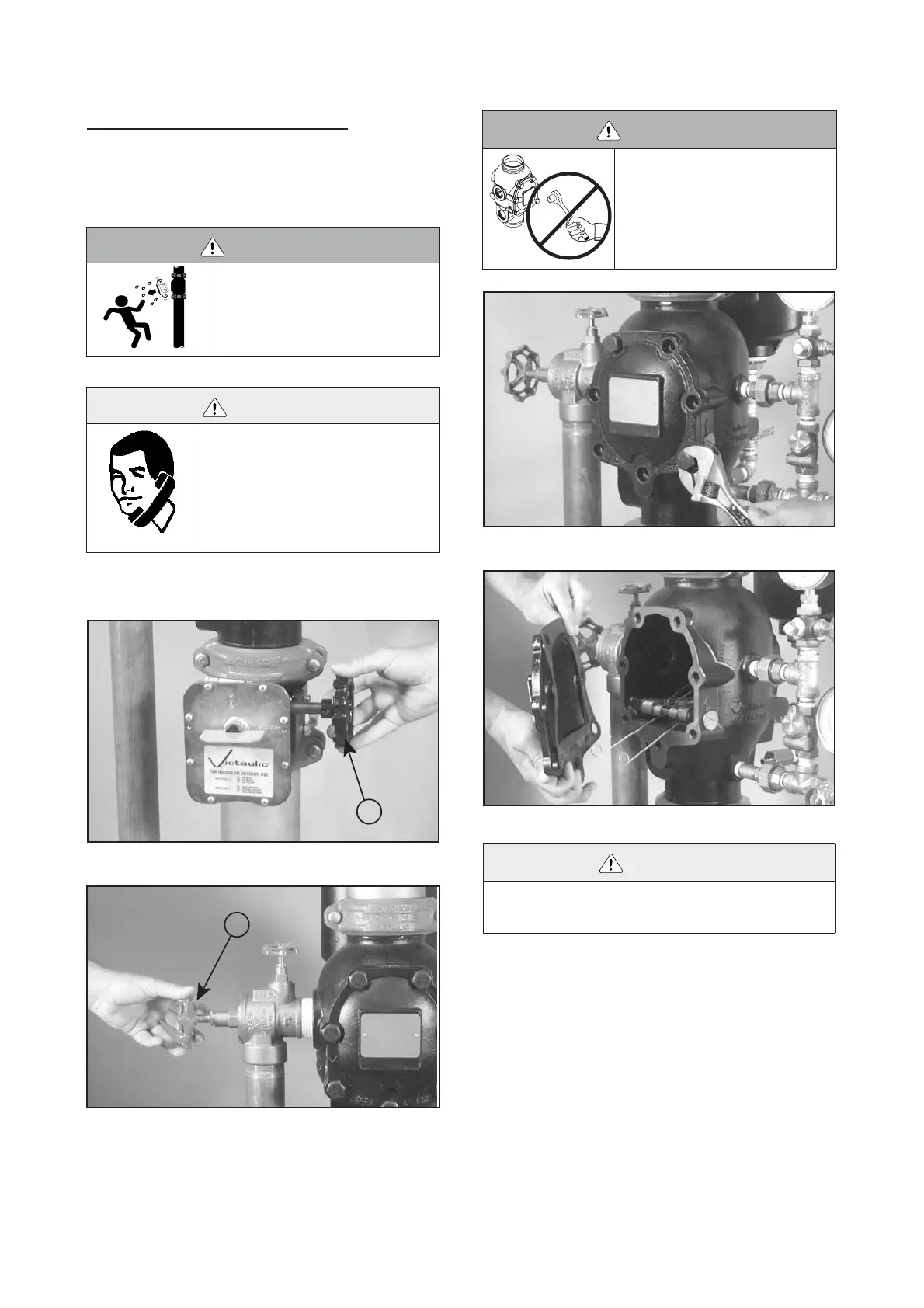

4. After all pressure is released from the system, remove all

cover plate bolts slowly.

4a. Remove the cover plate and cover plate gasket.

WARNING

• Depressurize and drain the piping system

before attempting to install, remove, or adjust

any Victaulic piping products.

Failure to follow this instruction could cause

serious personal injury and/or property damage.

CAUTION

• Any activities that require taking the valve out of

service may eliminate the fire protection provided.

• Before servicing or testing the system, notify the

authority having jurisdiction.

• Consideration of a fire patrol should be given in

the affected areas.

Failure to follow these instructions could cause seri-

ous personal injury and/or property damage.

3

14

WARNING

• Make sure the valve is depressurized and

drained before removing the cover plate

bolts.

The cover plate could blow off if these bolts are

removed while the valve is pressurized, result-

ing in serious personal injury and/or property

damage.

CAUTION

• DO NOT use solvents or abrasives on or near the valve body seat ring.

Failure to follow this instruction could prevent the clapper from sealing prop-

erly, resulting in improper operation, valve leakage, and/or property damage.

Loading...

Loading...