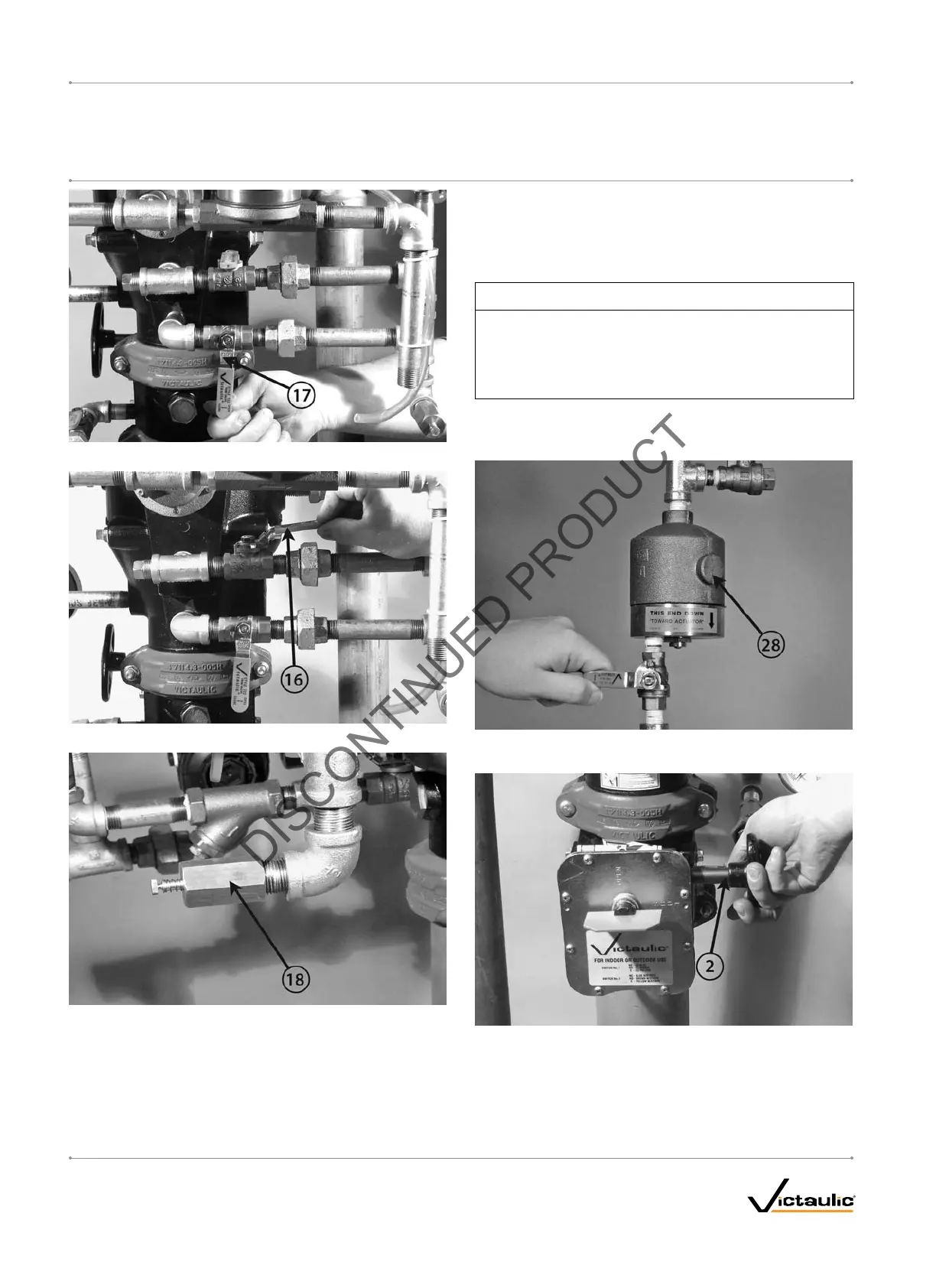

7. Confirm that the alarm test ball valve (17) is closed.

8. Open the alarm line ball valve (16).

9. Confirm that there is no leakage from the intermediate valve cham-

ber. The restricted orifice/alarm line drain (18) should not be leak-

ing water or air.

10. Notify the authority having jurisdiction, remote station alarm moni-

tors, and those in the affected area that the valve is back in ser-

vice.

11. Provide test results to the authority having jurisdiction, if required.

WATER LEVEL AND LOW AIR ALARM TESTS

The authority having jurisdiction may have standards that require water

level and low air alarm tests on a more frequent basis than national

requirements. Verify these requirements by contacting the authority

having jurisdiction in the affected area.

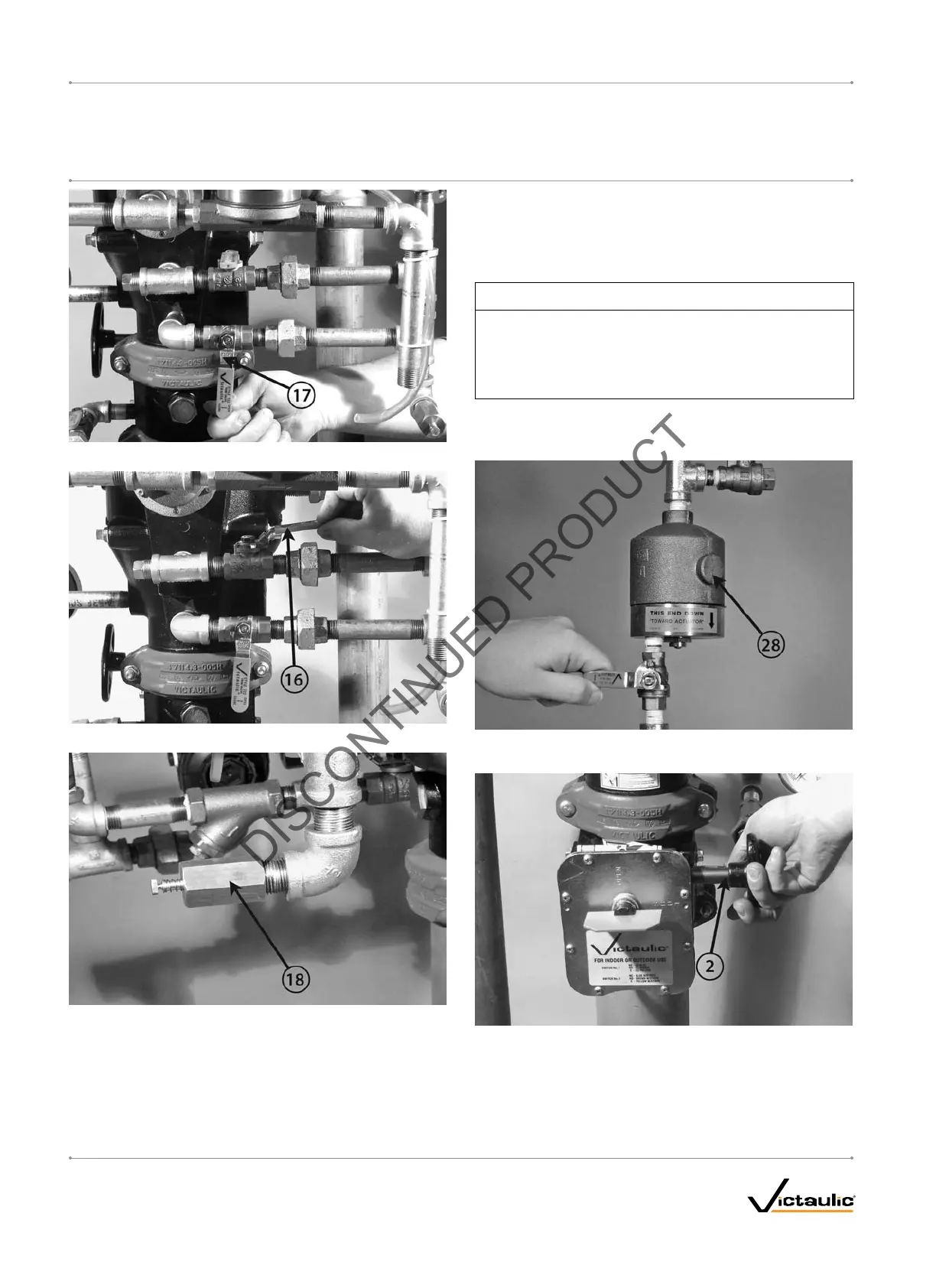

NOTICE

If a Series 746-LPA Dry Accelerator is installed, make sure the

authority having jurisdiction is notified that the water level and

low air alarm tests are in progress. Failure to close the isolation

ball valve of the Series 746-LPA Dry Accelerator may cause the

valve to trip, resulting in a false alarm.

•

1. Notify the authority having jurisdiction, remote station alarm moni-

tors, and those in the affected area that the water level and low air

alarm tests will be performed.

2. If a Series 746-LPA Dry Accelerator (28) is installed, close the iso-

lation ball valve.

3. Close the water supply main control valve (2).

I-756LPA.VDS_18

FireLock

®

European Dry Valve Stations

SERIES 756

WITH SERIES 776 LOW-PRESSURE ACTUATOR

I-756LPA.VDS

INSTALLATION, MAINTENANCE, AND TESTING MANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2006 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_B

Loading...

Loading...