WARNING

Make sure the valve is depressurized and

drained completely before the cover plate

bolts are removed.

The cover plate could blow off if the cover plate

bolts are removed while the valve is pressur-

ized, resulting in serious personal injury and/or

pr

operty damage.

•

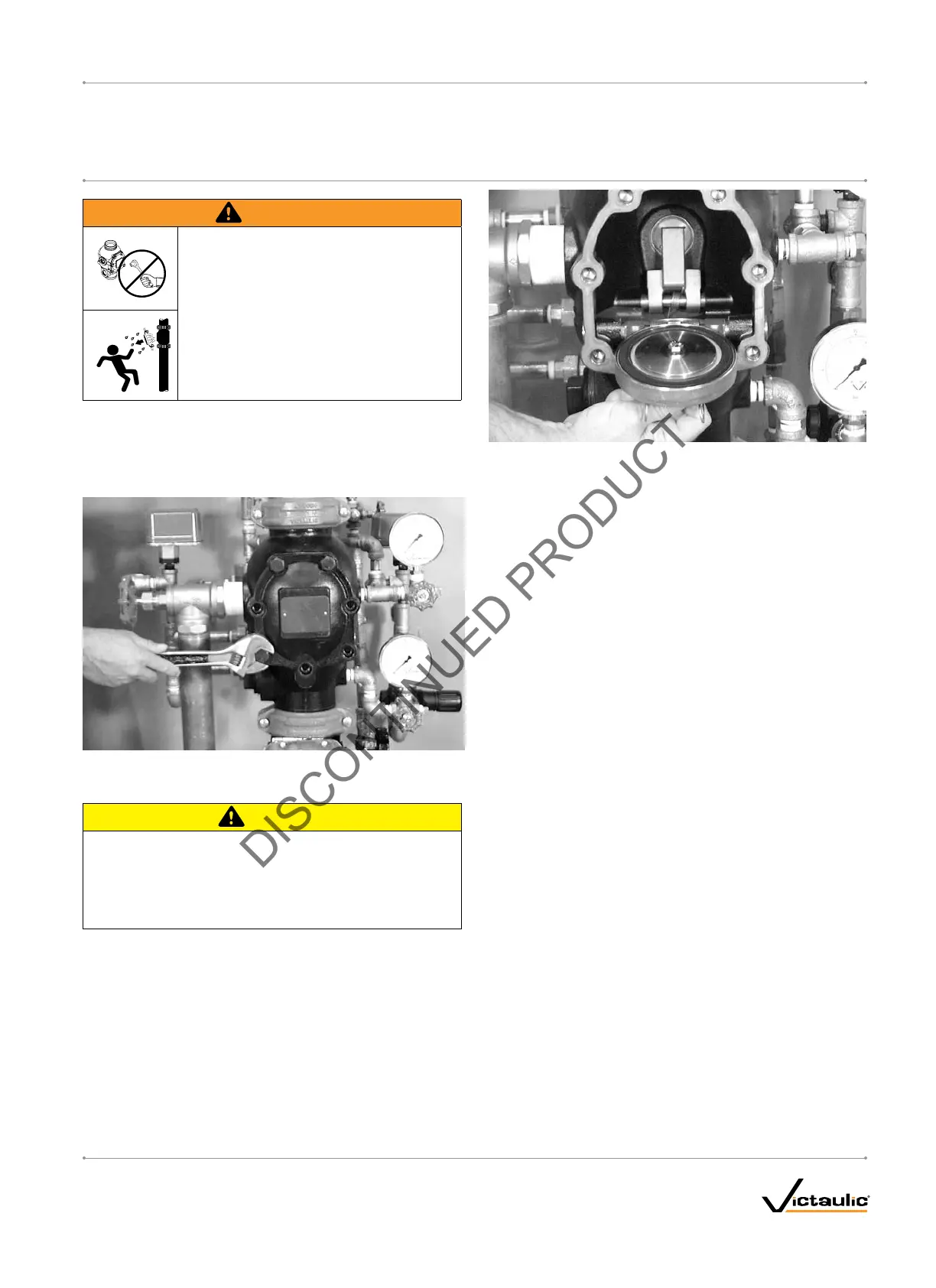

6. PUSH DOWN ON THE AUTO DRAIN SCREW (12) TO REMOVE

PRESSURE IN THE PISTON CHARGE LINE.

7. After all pressure is released from the system, loosen the cover

plate bolts slowly. NOTE: DO NOT remove any cover plate bolts

until all cover plate bolts are loosened.

8. Remove all cover plate bolts, along with the cover plate and cover

plate gasket.

CAUTION

DO NOT use solvents or abrasives on or near the valve body

seat ring.

Failure to follow this instruction could prevent the clapper

from sealing, resulting in improper valve operation and/or valve

leakage.

•

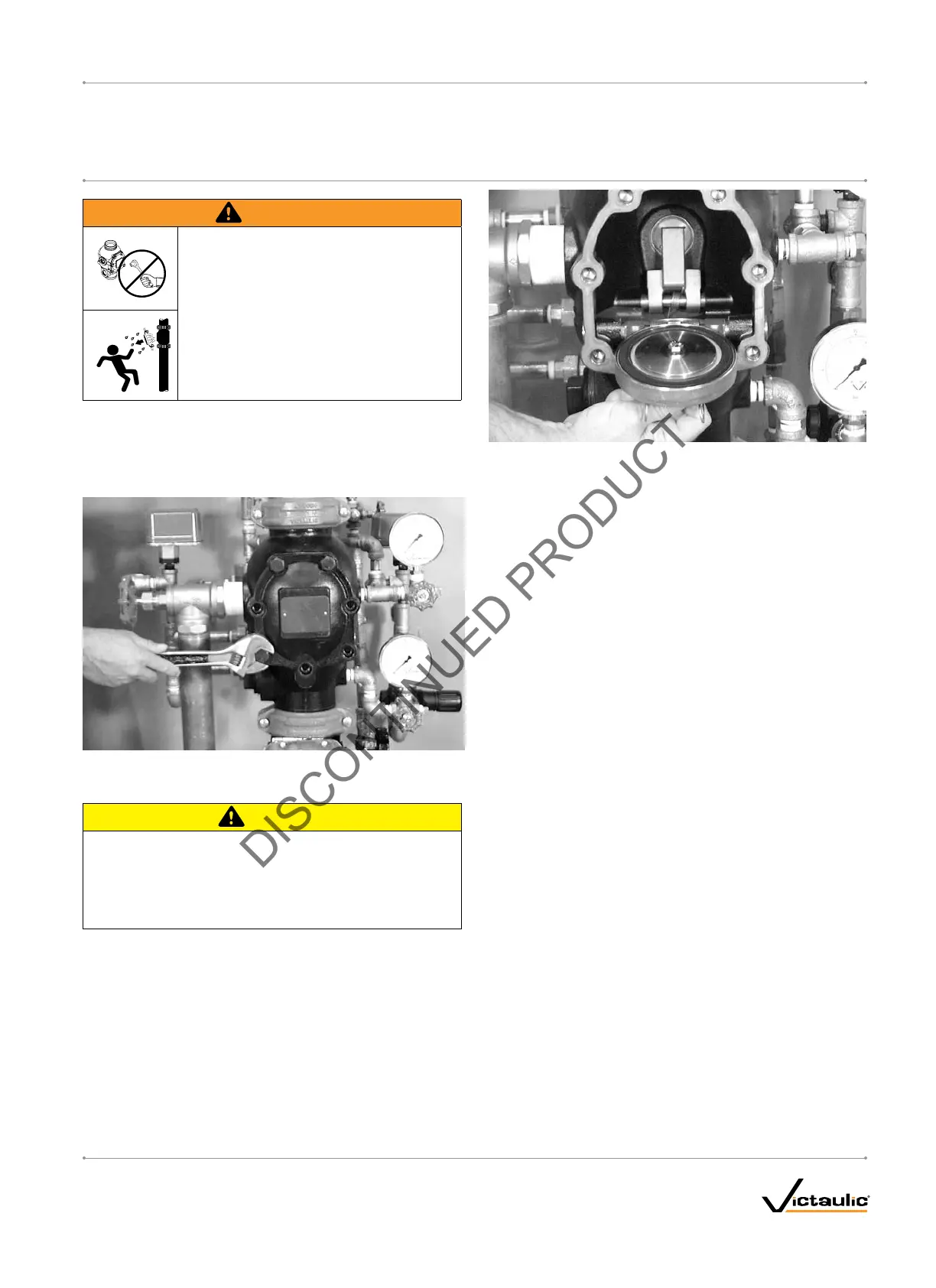

9. Rotate the clapper out of the valve body. Inspect the clapper seal

and seal-retaining ring. Wipe away any contaminants, dirt, and

mineral deposits. Clean out any holes that are plugged in the

valve-body seat ring. DO NOT USE SOLVENTS OR ABRASIVES.

10. Inspect the clapper for freedom of movement and physical

damage. Replace any damaged or worn parts by following the

applicable instructions in the "Maintenance" section, starting on

page 32.

11. Re-install the cover plate by following the "Installing the Cover

Plate Gasket and Cover Plate" section, starting on page 35.

12. Place the system back in service by following the "Placing the

System in Service" section, starting on page 11.

I-756LPA.VDS_25

FireLock

®

European Dry Valve Stations

SERIES 756

WITH SERIES 776 LOW-PRESSURE ACTUATOR

I-756LPA.VDSINSTALLATION, MAINTENANCE, AND TESTING MANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2006 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_B

Loading...

Loading...